Laser Plastic Welding Machines from Evosys

Laser welding plastic is cleaner, safer, more accurate and more repeatable than other more traditional methods of welding plastic components.

We provide highly reliable laser systems for the automotive, medical technology and the consumer goods industry. Our laser welding machines can either stand alone or be integrated into your production line and are ideal for:

- welding plastic components

- welding plastic film

- welding plastic parts

- welding plastic tubing

Full Production Line Integration

The importance of laser plastic welding continues to increase due to the many technical advantages that laser welding brings with it.

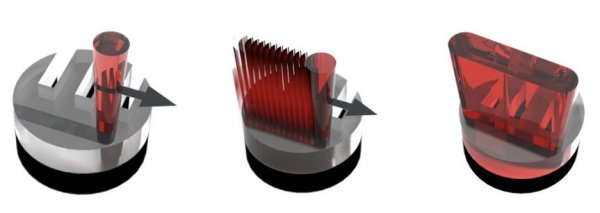

- Contour welding - the weld seam is traced once or several times with the laser but the plastic is only melted at the point of direct laser impact before immediately solidifing again, so there is no melt expulsion.

- Simultaneous Welding - where the entire weld seam is heated and melted by one or more beam sources simultaneously

- Quasi-simultaneous Welding - where all areas of the weld seam are heated and melted almost simultaneously.

- Radial Welding - a special type of contour welding for processing radially symmetrical assemblies.

If you would like to integrate a laser plastic welding machine into your round the clock production line, we will advise you the best machine for your purposes. See below for fact sheets and specifications and please feel free to contact our sales team for more information.

Stand-alone Plastic Welding Systems

One of the more recognisable applications of plastic laser welding technology is the production of tail lights for the automotive industry. The laser welding of these parts can be achieved using stand alone laser plastic welding equipment.

Data Sheets