Talk to Us!

Connect with our Technical & Support Team.

Key Feature

Precision Repairs for Critical Components

Laser cladding excels in precision repairs, restoring worn or damaged components to their original specifications. This reduces downtime and material waste, offering a cost-effective and sustainable solution for maintaining critical parts in high-performance applications.

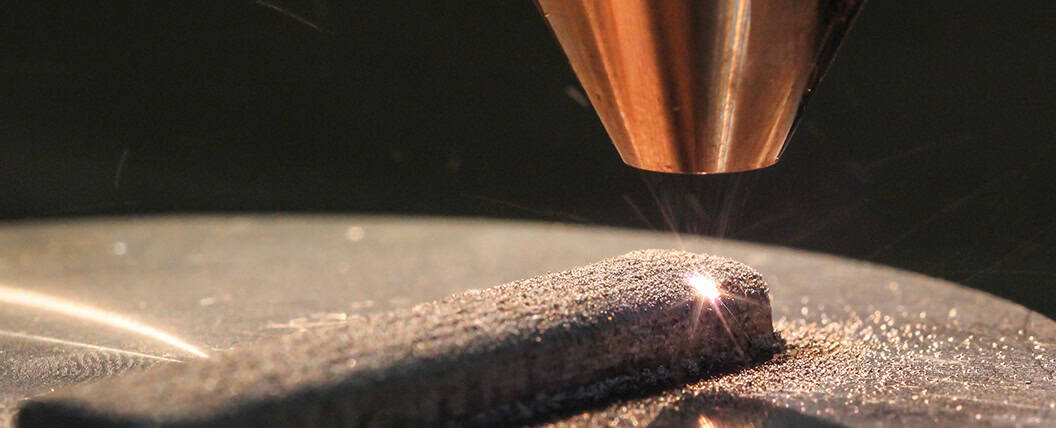

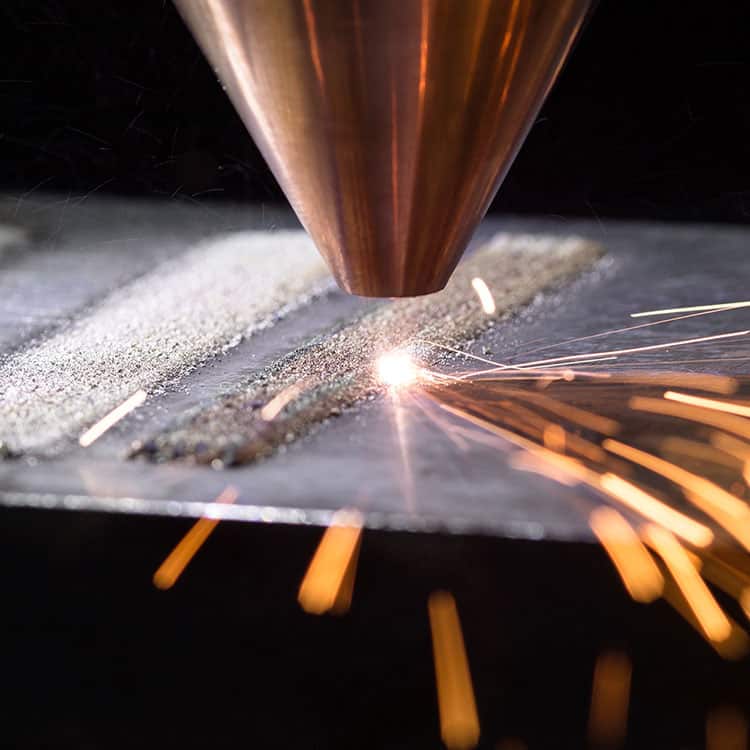

Information About Laser Cladding

Laser cladding works by melting a powdered or wire material onto a substrate using a high-energy laser beam. This creates a metallurgical bond that integrates the coating seamlessly with the base material. The process allows for precise application with minimal heat distortion, ensuring enhanced surface properties such as hardness, corrosion resistance, and wear protection. Unlike traditional welding, laser cladding provides superior control and uniformity, making it ideal for high-precision applications.

Laser Cladding for UK Industries

Laser cladding is versatile and delivers tailored solutions across industries, enhancing the durability and efficiency of critical components.

Strengthen turbine blades and repair components to meet stringent aerospace standards.

Protect and repair high-wear parts like engine components and transmission gears.

Extend the lifespan of machinery components by restoring and reinforcing surfaces.

Enhance the durability of heavy-duty equipment and structural components.

Repair and protect tooling surfaces, improving performance and reducing costs.

Reinforce components to resist wear and corrosion in harsh operational environments.

Improve the performance of turbines, generators, and other critical energy systems.

Strengthen rail components for enhanced durability under heavy loads.

Laser Cladding Materials

Laser cladding provides exceptional results for a variety of metals, delivering enhanced performance and longevity.

Achieve superior wear resistance and corrosion protection on steel, aluminium, and other alloys.

Answering Your Questions

Frequently Asked Questions

Laser Cladding can be used for metals Such as stainless steel, nickel-based alloys, cobalt-based alloys, and titanium.

Laser cladding is utilised across various industries for applications including:

- Surface Enhancement: Applying wear-resistant or corrosion-resistant coatings to extend the lifespan of components.

- Component Repair: Restoring dimensions and functionality of worn or damaged parts, such as turbine blades and moulds.

- Additive Manufacturing: Building up material to create complex geometries or near-net-shape parts with minimal post-processing.

Industries such as aerospace, automotive, power generation, and oil and gas benefit from laser cladding due to its precision and efficiency.

Laser cladding is a process that involves depositing material onto a substrate using a laser to melt the feedstock, which can be in powder or wire form. The laser creates a melt pool on the substrate’s surface, into which the feedstock is introduced, resulting in a metallurgical bond upon solidification. This technique is used to enhance surface properties, repair worn components, or fabricate near-net-shape parts. The process offers advantages such as low dilution between the clad and substrate materials, minimal thermal distortion, and the ability to apply coatings with precise control over thickness and composition.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.