Laser Rust Removal

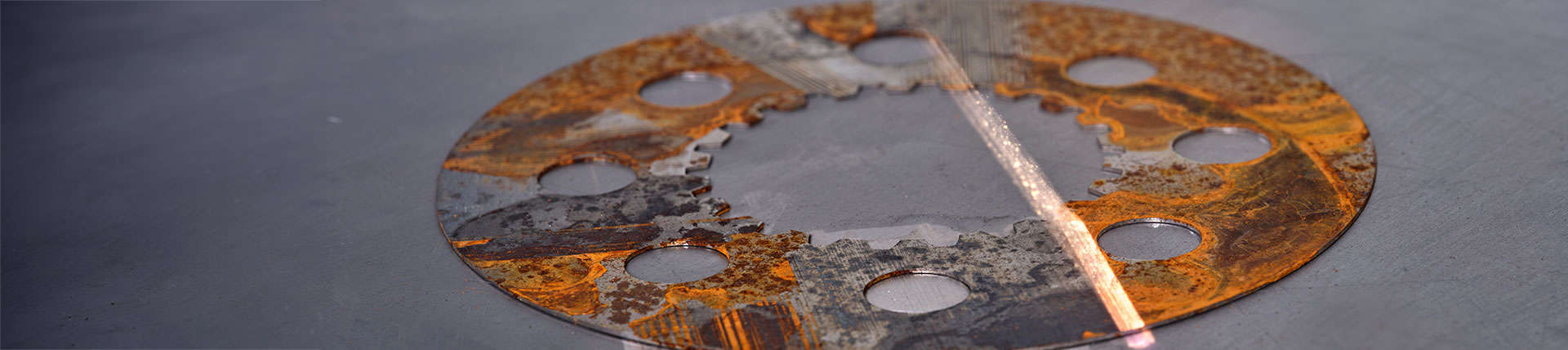

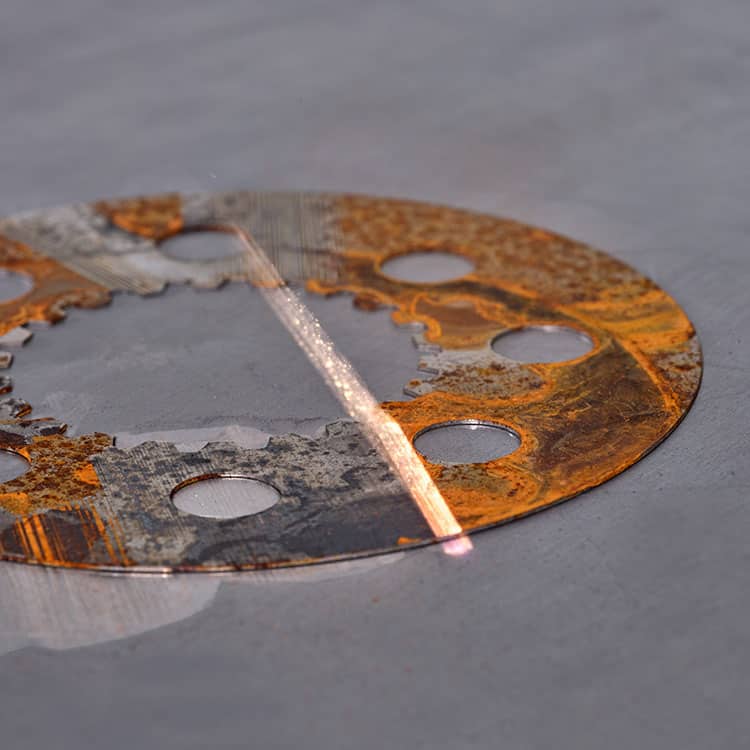

Laser rust removal is revolutionising surface preparation across industries. By using high-powered laser beams to vaporise rust and other impurities, this non-abrasive and chemical-free method ensures a clean, rust-free surface without damaging the underlying metal.

How Laser Rust Removal Works

Laser rust removal operates on the principle of ablation. A focused laser beam is directed at the rusted surface, where it is absorbed by the rust layer. The rust heats up and vaporises, leaving the metal underneath clean and untouched. The precision of this process allows it to target specific areas without spilling over onto surrounding surfaces, making it ideal for intricate and delicate parts.

- High Precision: The laser beam is finely tuned to remove rust layer by layer, ensuring no impact on the substrate.

Non-Contact Process: The laser does not physically touch the material, eliminating the risk of scratching or deforming delicate parts.

Versatility: Adjustable settings allow the laser to be tailored to different rust levels, surface areas, and materials.

Advantages of Laser Rust Removal

1. Non-Abrasive and Safe for Substrates

Unlike sandblasting or grinding, laser rust removal doesn’t wear down or damage the substrate. This ensures the integrity of even the most delicate components, extending their lifespan.

2. Environmentally Friendly

Laser cleaning produces no secondary waste such as chemical residues, abrasives, or pollutants. This makes it a sustainable option for industries aiming to reduce their environmental impact.

3. Cost-Effective

While the initial investment may be higher, laser rust removal eliminates the ongoing costs of consumables like chemicals or abrasives. It also reduces maintenance and downtime, resulting in long-term savings.

4. Automation and Repeatability

Laser systems can be automated for industrial-scale applications, ensuring consistent and repeatable results. This makes them ideal for production lines and large-scale operations.

5. Versatility Across Applications

Lasers can handle various levels of rust and corrosion, from light surface oxidation to deep-seated rust layers, making them adaptable for a wide range of industries.

Applications of Laser Rust Removal

1. Industrial Machinery and Tools

Remove rust and impurities from machinery and tools without affecting their precision or functionality. Laser cleaning ensures equipment remains in optimal working condition, reducing downtime.

2. Automotive Industry

Clean car body panels, wheels, and components efficiently. Laser rust removal prepares surfaces for painting or welding, ensuring higher-quality finishes and stronger bonds.

3. Aerospace Components

Remove oxides, contaminants, and rust from aircraft parts with precision. Laser cleaning meets the stringent safety and quality standards required in aerospace manufacturing.

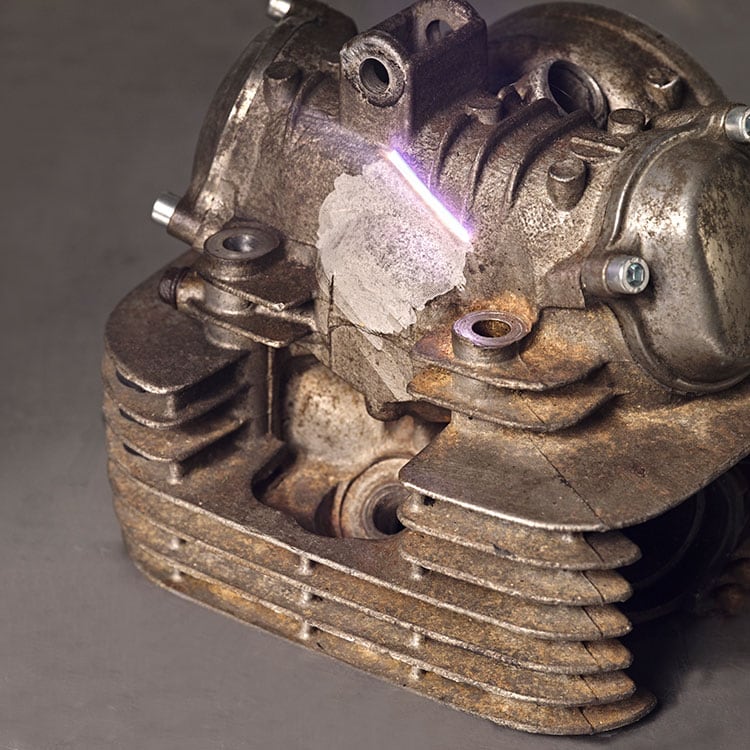

4. Historical Restoration

Delicately remove rust and dirt from historical artefacts, sculptures, and antiques. The laser’s precision allows for cleaning without damaging the original material or details.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.