Talk to Us!

Connect with our Technical & Support Team.

Key Feature

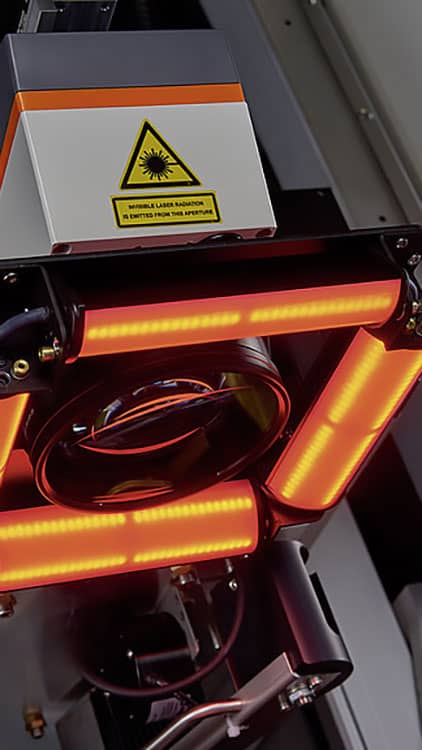

Medical Marking

Traceability and precision are crucial in the medical sector, and our advanced laser systems help manufacturers achieve unparalleled compliance

UDI (Unique Device Identification) is now mandatory for most medical devices and packaging, requiring detailed markings such as date codes, batch numbers, expiry dates, and serial numbers. Laser marking delivers the most reliable direct part marking, offering high-contrast, permanent details for optimal traceability. As medical marking experts, we provide a range of solutions for contamination-free, non-distorting, and permanent markings.

Information About Laser Marking & Engraving

Do you need marking or engraving and what’s the difference?

Laser marking and laser engraving are both precision techniques, but they differ in depth and application:

- Laser Marking: A non-contact process that discolours the surface of the material, creating high-contrast marks without penetrating deeply. It’s ideal for barcodes, logos, and text, ensuring minimal material impact while providing permanent identification.

- Laser Engraving: A process that physically removes material to create deeper, more durable marks or designs. This method is suitable for applications needing a more tactile result, such as serial numbers or custom artwork on metal or plastic.

Both methods provide permanent solutions, but engraving involves more depth and durability, while marking is quicker and preserves the surface.

Laser Marking & Engraving for UK Industries

Our laser marking and engraving systems have been assisting manufacturing industries in future proofing their production operations.

Laser Marking & Engraving Materials

Laser marking and engraving are premium solutions for various materials, from plastics to metals to organics.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.