Laser Systems

IL C4600

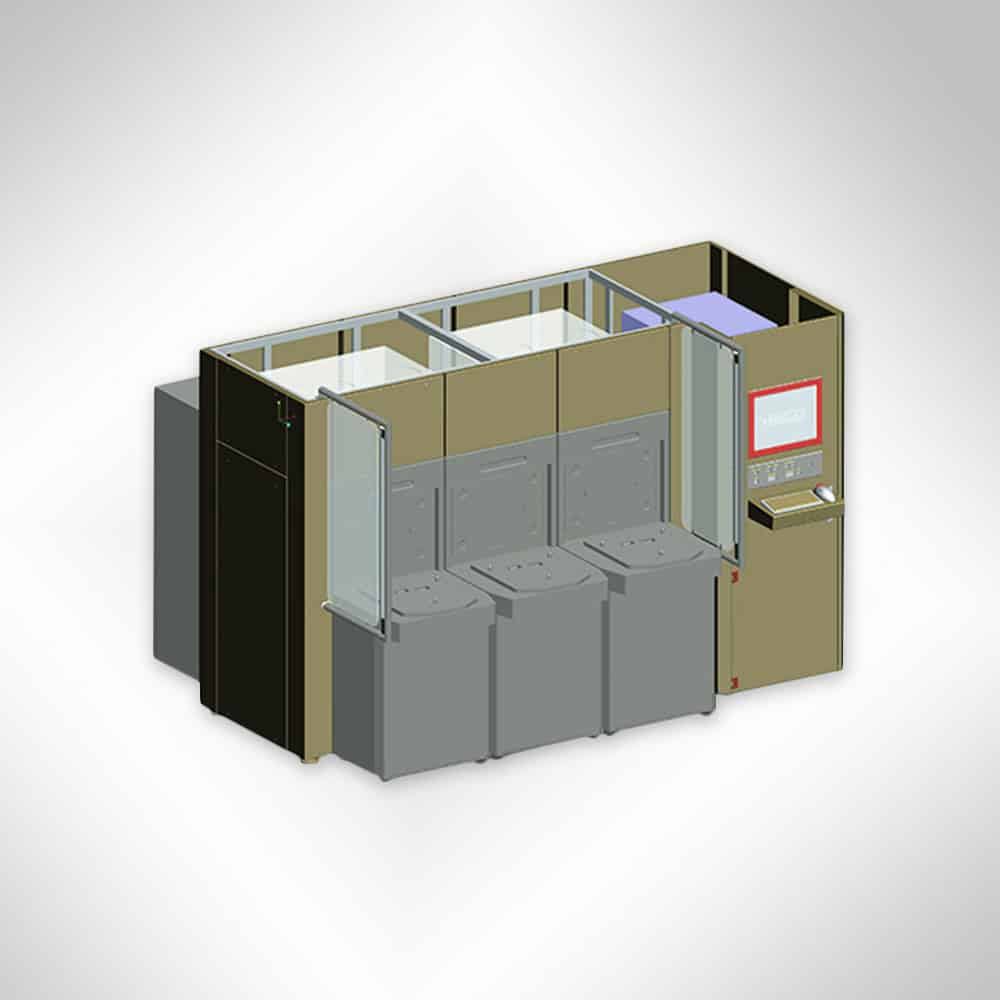

The IL C4600 from InnoLas is a high-capacity wafer sorting system designed for 450 mm wafers. With a throughput of up to 300 wafers per hour, it offers advanced sorting modes and precise handling for semiconductor production.

Laser Systems

Semiconductor Processing

The IL C4600 by InnoLas Semiconductor is a robust wafer sorting system tailored for high-precision and high-throughput semiconductor production. Designed to handle 450 mm wafers, the system features a single-arm robot with a double end-effector for precise and reliable wafer transfers. It supports sorting tasks at a throughput of 180 wafers per hour and transfer tasks at 300 wafers per hour. The IL C4600 offers flexible sorting options based on wafer ID, weight, and thickness, with modes such as ascending, descending, random, split, and merge. The system accommodates up to seven loading stations and supports AGV, PGV, and OHT cassette loading systems. Built with a stainless steel frame, ISO 3 mini-environment compliance, and CE certification, the IL C4600 ensures reliable performance and seamless integration into modern production environments. Its advanced handling features and configurable sorting modes make it an ideal choice for large-scale semiconductor manufacturing.

Send a Product Request

Product Form

Contact form for product pages

"*" indicates required fields

Laser Cleaning

Related Laser Cleaning Systems

Answering Your Questions

Frequently Asked Questions

Reviews

Don't Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.