Talk to Us!

Connect with our Technical & Support Team.

Key Feature

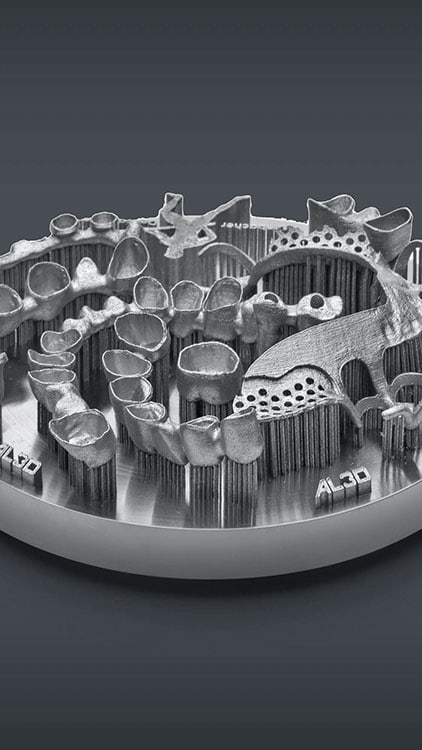

Precision in Complex Geometries

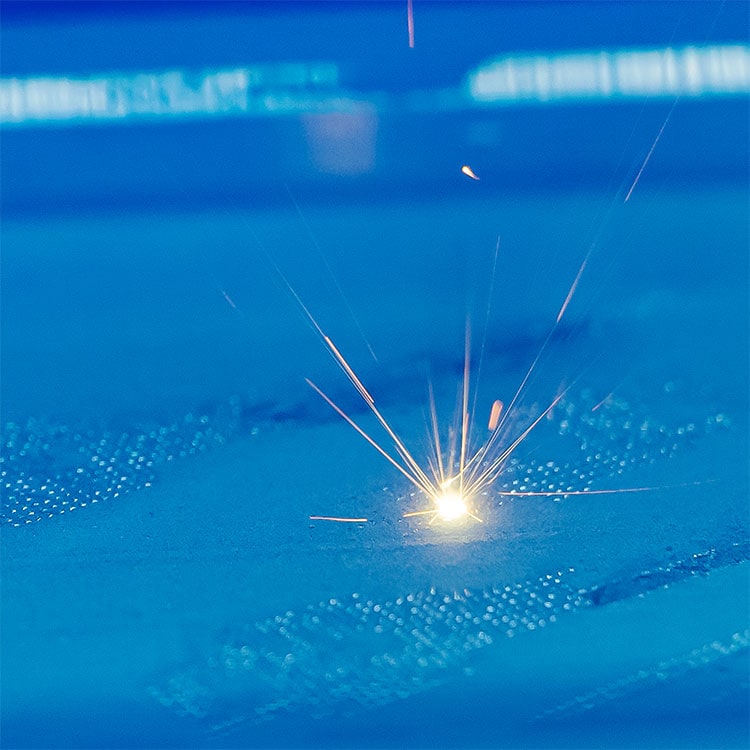

The standout feature of laser 3D metal printing is its ability to achieve highly detailed and complex geometries with a very fine laser spot. This capability is particularly beneficial for industries where precision is critical, such as medical implants and aerospace components.

Information About Laser Metal 3D Printing

These systems utilise a closed powder circuit system to ensure safety by preventing any direct contact with the metal powder during the printing process. They are designed for optimum detail accuracy and are equipped with powerful lasers that enable the creation of components with a density greater than 99%, ensuring the mechanical properties of the printed parts match those of the bulk material.

Laser Metal 3D Printing for UK Industries

Laser metal 3D printing is versatile and pivotal across various sectors, offering modern solutions for manufacturing across many industries such as:

Laser metal 3D printing is ideal for producing bespoke medical implants and prosthetics with tailor-made fits for individual patients.

Laser metal 3D printing is capable of fabricating lightweight, structurally complex components that meet rigorous industry standards.

Laser metal 3D printing supports the production of durable, high-performance parts that can withstand the demands of automotive use.

Laser metal 3D printing provides solutions for creating robust, custom parts for specialised machinery.

Aids in the manufacture of intricate components used in electrical and electronic devices.

Perfect for creating intricate designs and custom pieces in precious metals.

Laser 3D Printing Materials

This technology significantly reduces material waste supporting more sustainable manufacturing practices.

Our systems handle a variety of metals, including but not limited to Iron alloys, Nickel based alloys, Cobalt chrome alloys and precious metals.

Answering Your Questions

Frequently Asked Questions

The AL3D-METAL 200 is particularly suited for industries requiring high precision and intricate designs, such as precision mechanics, medical technology, dental, and jewellery sectors, as well as research and development laboratories. Its ability to produce complex geometries with fine detail makes it ideal for creating customised components, prototypes, and small series productions. The printer’s efficient material usage and safe powder handling are advantageous when working with high-value materials, making it a valuable tool for producing high-quality metal parts across various applications.

The AL3D-METAL 200 features a closed powder circuit that prevents operator contact with metal powders during the entire printing process, enhancing workplace safety. Its intelligent cartridge system simplifies material supply, enables quick process preparation, and ensures high material utilisation, which is particularly beneficial when working with expensive or precious metals. Additionally, the system includes the AL3D-CABIN unpacking station, providing a closed process chamber for the safe separation of sintered components from residual powder and facilitating the collection and potential reuse of leftover material.

The AL3D-METAL 200 is a 3D metal printer developed by ALPHA LASER GmbH, designed for the additive manufacturing of high-precision metal components. Key features include a 200 W fibre laser with a 50 µm focus diameter, a closed powder handling system for enhanced safety, an innovative cartridge system for efficient material usage, and a compact footprint of 600 × 617 mm, making it suitable for environments with limited space. The printer supports a variety of materials, including iron alloys, nickel-based alloys, cobalt-chrome alloys, precious metals, and reactive metals.

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.