Talk to Us!

Connect with our Technical & Support Team.

Key Feature

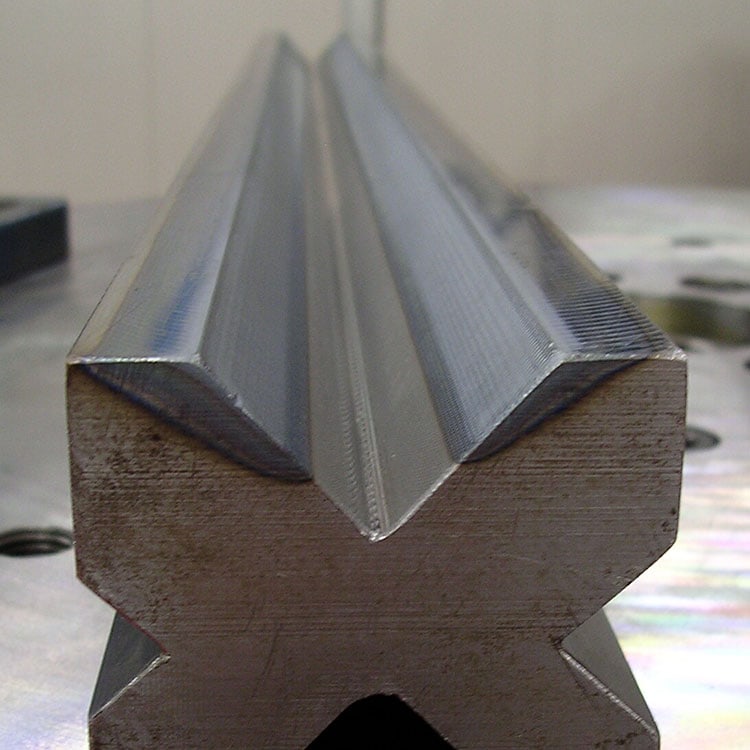

Tool & Die Hardening

Laser hardening significantly enhances the longevity and performance of tools and dies by creating wear-resistant surfaces. This precise process ensures extended tool life, reduced maintenance costs, and improved efficiency for demanding industrial applications.

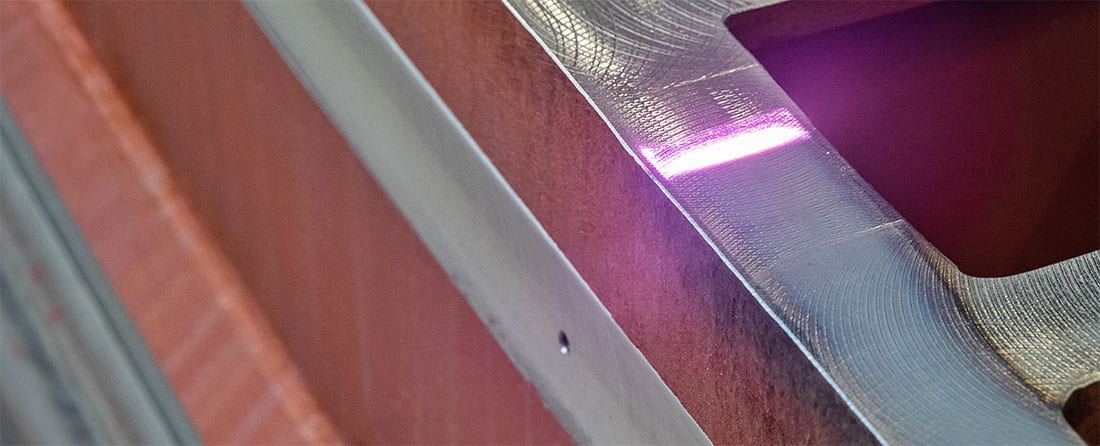

Information About Laser Hardening

Laser hardening as an application works by rapidly heating the metal surface using a focused laser beam, followed by controlled cooling. This process transforms the microstructure of the metal, creating a hardened layer while preserving the core’s toughness. Unlike traditional hardening methods, laser hardening targets only the required areas, reducing material distortion and enhancing precision.

Laser Hardening for UK Industries

Laser hardening provides tailored solutions for industries requiring durable and wear-resistant components, ensuring superior performance under demanding conditions.

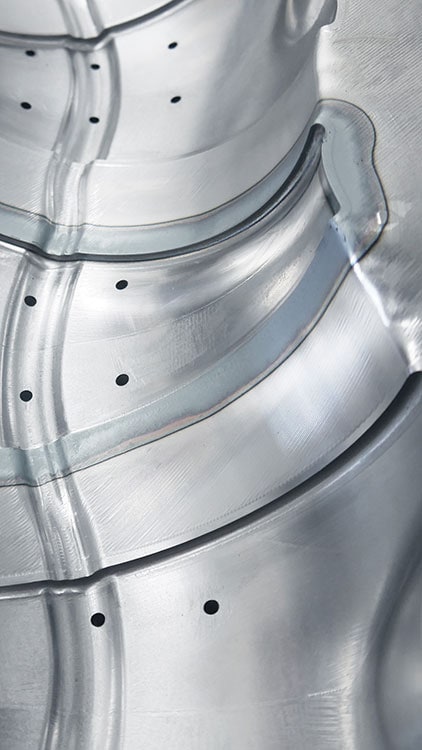

Laser Hardening Materials

Laser hardening is a versatile solution for enhancing the surface properties of various metals, delivering increased strength and durability.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.