Talk to Us!

Connect with our Technical & Support Team.

Key Feature

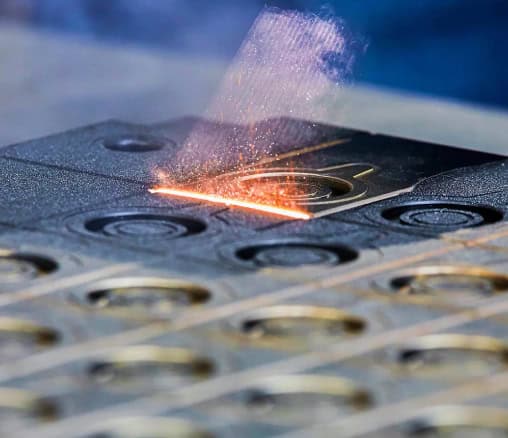

Laser Mould Cleaning

Laser cleaning removes residues such as mould release agents, burnt polymers, and carbon deposits from dies and moulds. The process preserves the surface texture and ensures dimensional accuracy, essential for high-quality production.

Information About Laser Cleaning

Laser cleaning uses focused continuous wave or pulsed top hat laser beam profiles to remove paint, rust, and contaminants from surfaces in a precise, non-contact, and eco-friendly manner.

Laser Paint Removal

Laser technology efficiently removes paint and coatings from surfaces without damaging the underlying material. It is ideal for delicate or complex shapes, where traditional methods might cause wear or environmental concerns.

Laser Rust Removal

Rust and corrosion are safely and effectively removed with lasers, restoring the original surface condition. This method minimises the need for harsh chemicals and mechanical abrasion, offering a cleaner, faster, and more sustainable solution.

Laser Contamination Removal

Lasers effectively remove contaminants like dirt, grease and any other release agent residues, providing a cleaner solution for industries like aerospace and automotive.

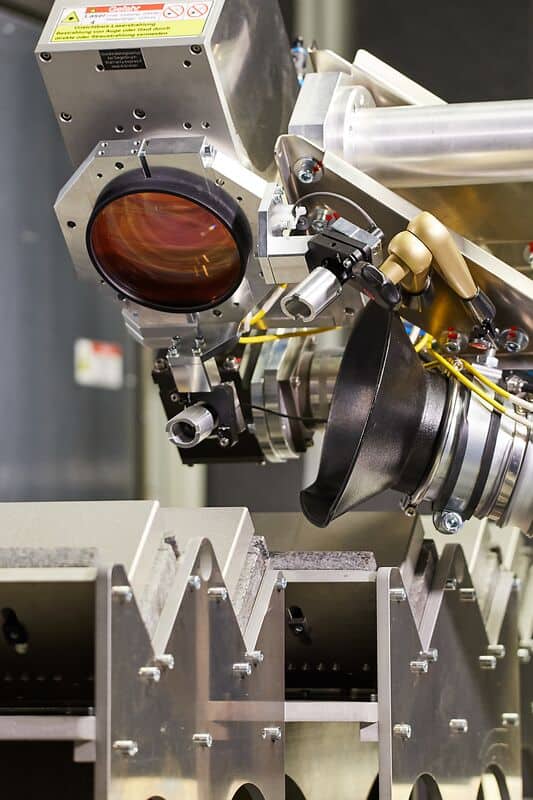

Laser Cleaning for UK Industries

Industrial laser cleaning systems from 4JET offers the ultimate process for quick removal of rust, paint and other contaminants from tools, moulds and components for many industries.

Laser Cleaning Materials

Our laser cleaning systems are designed to effectively remove contamination, coatings, and residues from a wide range of materials, making them ideal for industries where precision and surface integrity are critical.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.