FOBA Point & Shoot

Achieve manual laser marking precision with FOBA’s Point & Shoot system. Perfect for small-batch runs or dynamic production environments, this system ensures every mark is accurately placed with minimal effort.

Manual Mark Alignment Made Simple

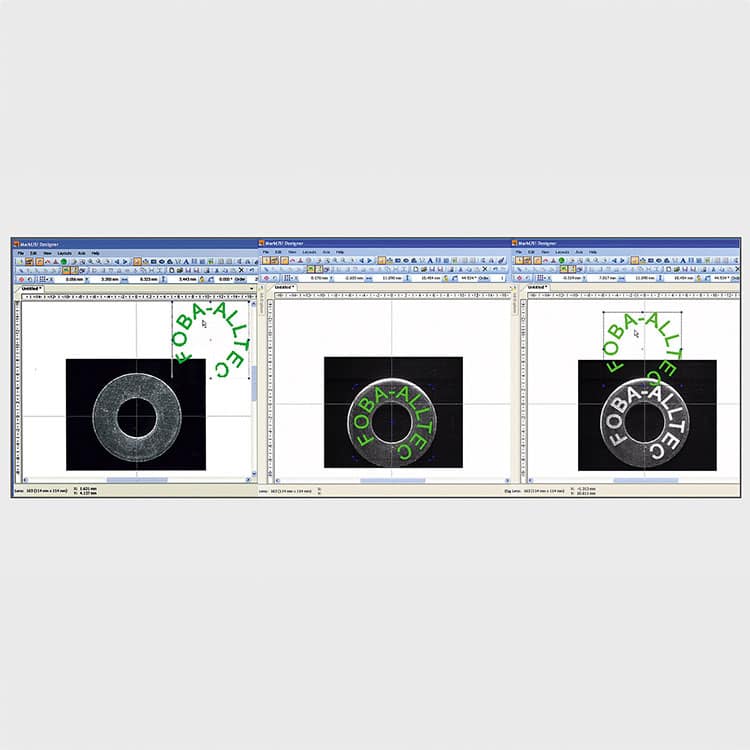

FOBA’s Point & Shoot™ vision system simplifies manual mark positioning for precise laser marking. Using a through-the-lens camera, it captures an image of the part to be marked, allowing the operator to position the marking visually via drag-and-drop directly on the captured image. Point & Shoot eliminates guesswork, reduces errors, and boosts productivity by ensuring markings are placed accurately on every product.

Key Features of Point & shoot

Visual Mark Alignment

The intuitive drag-and-drop interface lets operators align marks with precision. This feature removes the need for trial-and-error setups, significantly reducing setup time and enhancing accuracy.

What-You-See-Is-What-You-Get (WYSIWYG)

The WYSIWYG system previews how the final marking will appear, ensuring confidence in the process before the laser operation begins.

Seamless Integration with FOBA MarkUS

Point & Shoot is fully integrated into the MarkUS software, allowing operators to create marking jobs from pre-marked parts without needing additional part drawings.

Advantages of point & shoot

Enhanced Precision: Accurate positioning of markings ensures consistent results.

Reduced Waste: Fewer defective products due to pre-alignment verification.

Streamlined Workflow: Simplifies marking processes, even for complex parts.

Improved Productivity: Faster setup times translate to higher throughput.

Industry Applications for Point & Shoot

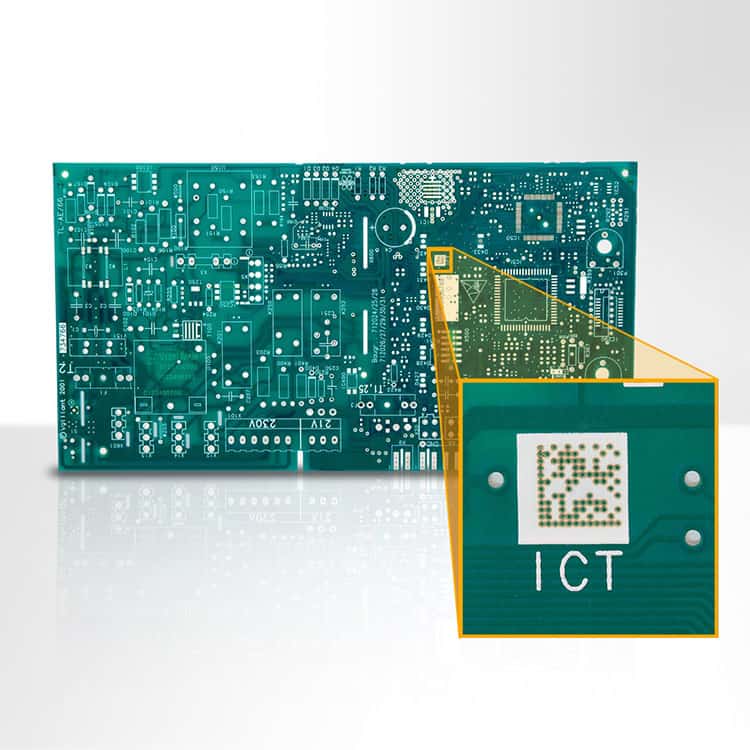

Electronics: Precise marking of circuit boards and components.

Automotive: Manual marking of VINs and other critical identifiers.

Aerospace: High-accuracy marking for traceability and compliance.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.