FOBA Mosaic

FOBA’s Mosaic vision system revolutionises laser marking by offering fixture-free flexibility and precision. Ideal for industries where efficiency and accuracy are paramount, Mosaic delivers unmatched ease of use and cost-effectiveness.

How Mosaic Works: Fixture Free Marking

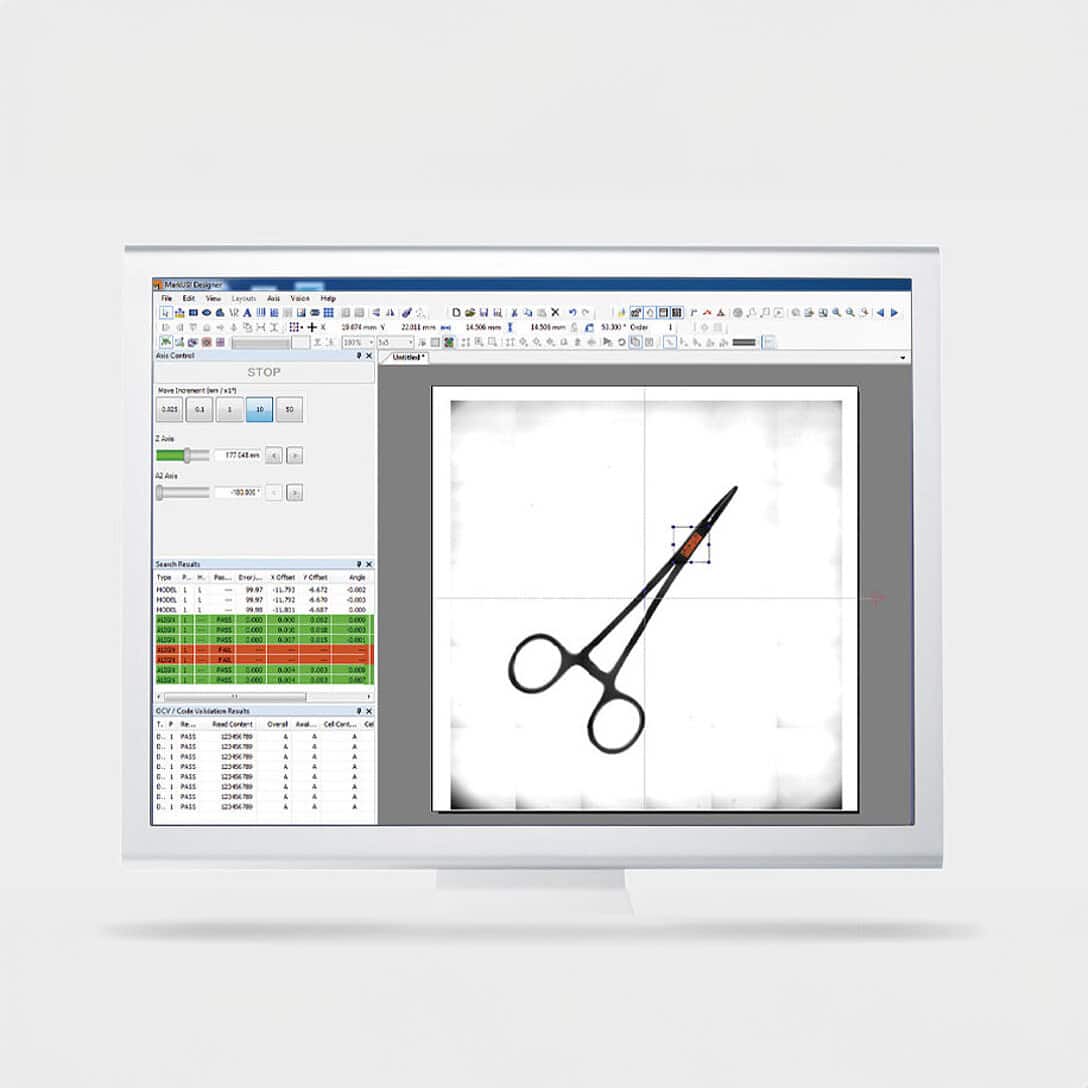

Mosaic leverages FOBA’s patented vision system technology to provide a simulated straight-down view of the marking field, eliminating the distortion typically caused by angled or external cameras. This process begins with the laser system’s integrated camera capturing multiple images of the part within the marking area. These images are then stitched together into a single, undistorted view.

Using this composite image, Mosaic allows operators to place markings precisely on the part, even if it’s irregularly shaped or placed arbitrarily within the marking field. The system adjusts for part position, orientation, and size, ensuring perfect alignment without the need for physical fixtures or pre-aligned positioning.

Key Features of Mosaic

Fixtureless Operation

Say goodbye to costly and time-consuming fixtures. Mosaic enables precise marking without the need for specialised part holders. Whether working with flat, curved, or irregularly shaped parts, the system adapts seamlessly, saving on tooling costs and simplifying workflows.

Distortion-Free Precision

Using advanced image stitching technology, Mosaic generates a composite straight-down view of the marking area. This ensures markings are perfectly aligned, regardless of part orientation or placement, eliminating errors caused by distorted perspectives from external cameras.

Simplified Workflow and Flexibility

Mosaic makes laser marking more accessible for operators by removing the need for exact part positioning. This streamlined process reduces setup time, enhances flexibility, and allows for rapid transitions between different part types or sizes, making it ideal for high-mix production environments.

Advantages of Mosaic

Enhanced Productivity

By eliminating the dependency on fixtures and minimising setup time, Mosaic accelerates production workflows. This results in higher throughput without compromising on marking quality, even for complex or large parts.

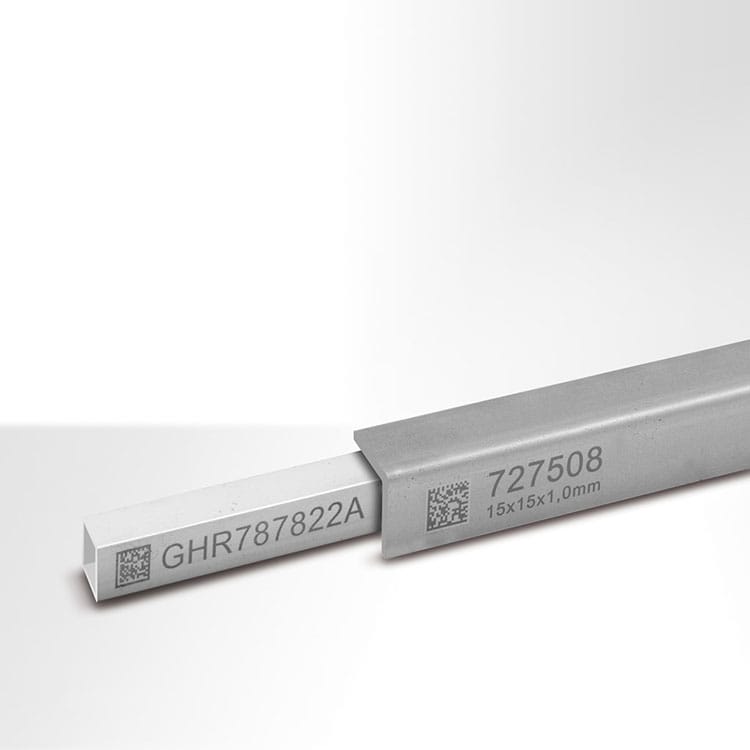

Versatile Applications Across Industries

From automotive components like brake discs and gears to medical devices requiring traceability, Mosaic’s adaptability makes it suitable for a wide range of applications. Its ability to handle large or irregular parts ensures it meets diverse industry needs with ease.

Cost Efficiency and ROI

Reducing fixture costs and setup complexity translates into significant savings. By enabling faster changeovers and reducing downtime, Mosaic offers a faster return on investment while maintaining consistent, high-quality results.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.