FOBA Intelligent Mark Positioning (IMP)

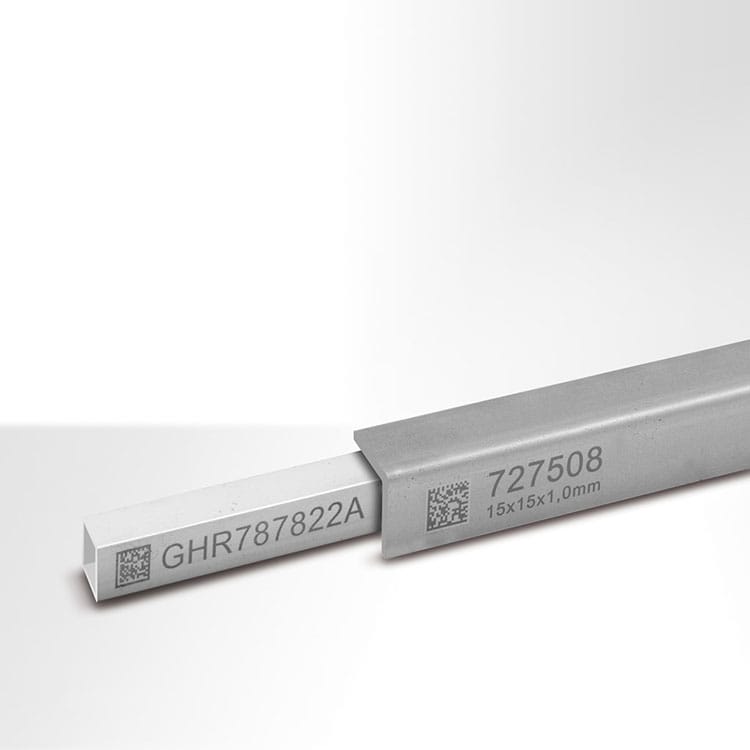

IMP ensures precise part alignment and verification, automating the marking process from premark validation to postmark inspection. It reduces the risk of errors, ensures consistent results, and enhances traceability, making it indispensable for high-accuracy marking workflows in industries like medical and aerospace.

What is IMP?: Precision, Efficiency, and Quality Assurance in Laser Marking

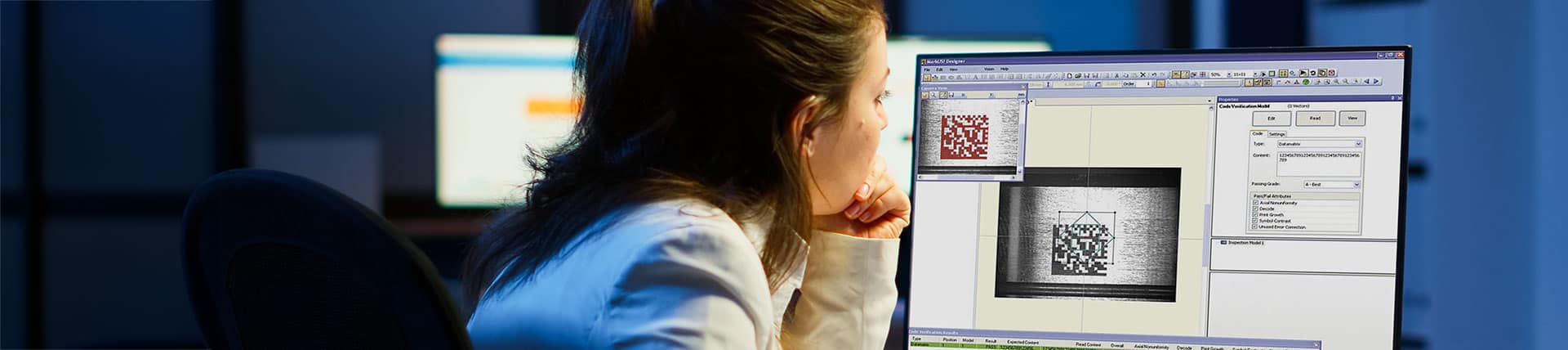

IMP integrates an advanced camera system directly into the FOBA MarkUS software, creating a cohesive and efficient solution for high-precision laser marking. The system not only detects the position and orientation of parts in real-time but also validates the marking process, minimising waste and maximising consistency.

By combining through-the-lens vision with automated alignment, verification, and validation, IMP revolutionises the marking process. Whether you’re working with medical devices, automotive components, or aerospace parts, IMP ensures unparalleled accuracy, repeatability, and compliance.

Key Features of IMP

Premark Verification

Ensures only unmarked parts are processed, avoiding duplication.

Confirms the correct part is positioned on the marking table.

Mark Alignment

Automatically adjusts the marking alignment for X, Y, and rotational shifts.

Guarantees accurate placement of every mark, reducing misalignment errors.

Postmark Verification

Validates the accuracy and completeness of markings, including Optical Character Verification (OCV).

Checks position, legibility, and content integrity of every mark.

Point & Shoot Integration

IMP includes all the features of FOBA’s Point & Shoot system, offering flexibility for semi-automated tasks.

Advantages of IMP

No Misaligned Parts: Automatic alignment ensures perfect positioning every time.

Integrated Vision: Through-the-lens imaging delivers superior precision.

Reduced Waste: Eliminates errors, saving materials and production time.

Machine-to-Machine Consistency: Reliable results across multiple systems.

Precision Without Fixturing: Reduces or eliminates the need for complex fixtures.

Industry Applications for iMP

IMP is designed to meet the most stringent demands of precision-focused industries:

Medical Devices: Achieve compliance with UDI markings for implants and surgical tools.

Automotive Components: Ensure consistent marking of VINs and other critical identifiers.

Aerospace: Deliver accurate markings for traceability on high-value parts.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.