FOBA Holistic Enhanced Laser Process (HELP)

Enhance your laser marking capabilities with FOBA’s HELP process, the ultimate solution for precision, reliability, and efficiency in direct part marking.

A 360° Laser Marking Workflow for Precision and Quality Assurance

HELP (Holistic Enhanced Laser Process) is FOBA’s most comprehensive and advanced laser marking process, integrating IMP (Intelligent Mark Positioning), Point & Shoot, and Mosaic vision technologies into a seamless, fixtureless workflow. Designed to meet the stringent demands of industries requiring absolute precision, HELP ensures accurate part validation and marking verification before and after the laser marking process.

How HELP Works

HELP operates in three stages:

Pre-Mark Validation

Confirms the correct part is loaded and correctly oriented.

Ensures no pre-marked or defective parts proceed in the workflow.

Marking

Executes the marking process with unparalleled precision using FOBA’s integrated vision systems.

Post-Mark Verification

Inspects the marked part for position, content accuracy, and quality, ensuring compliance with stringent standards.

Key Features of HELP

Fixtureless Workflow

HELP eliminates the need for part fixtures, saving costs and enhancing production flexibility. Parts are positioned directly in the marking area without the constraints of traditional fixtures.

Integrated Validation

Combines part and mark validation processes to detect errors at every stage. From loading to marking and final inspection, HELP ensures error-free operations.

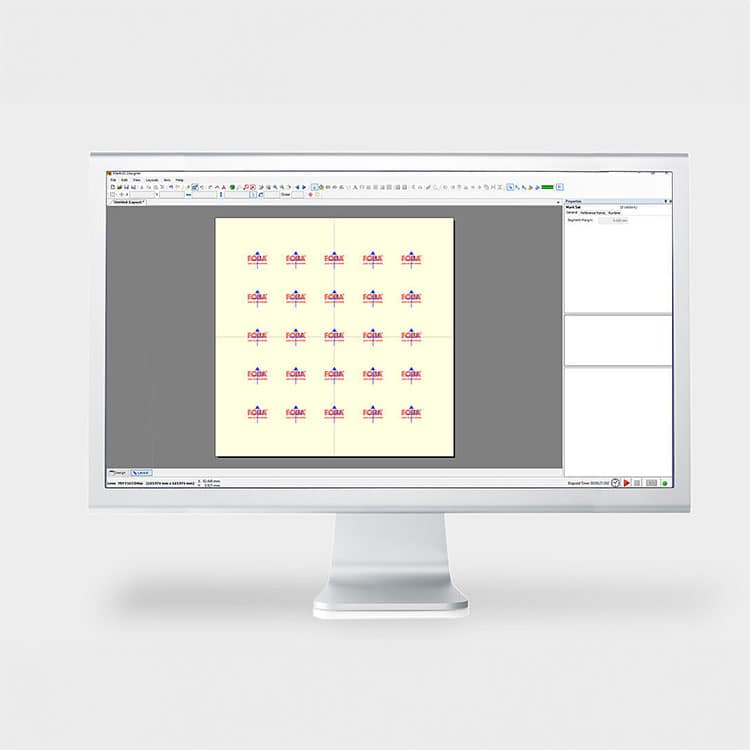

Advanced Vision Systems

Utilises FOBA’s industry-leading technologies, including IMP, Point & Shoot, and Mosaic, for unmatched accuracy and reliability.

Benefits of HELP

Error Reduction: Minimise operator and process errors with integrated validation.

Reduced Scrap: Ensures only defect-free parts continue in the production line.

Enhanced Productivity: Faster setup and streamlined workflows improve throughput.

Compliance Assurance: Meets the highest quality standards in regulated industries.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.