Precision Micro Welding Explained

Precision micro welding is at the forefront of joining miniature components with unmatched accuracy and minimal thermal distortion. Utilising laser technology, this advanced welding process meets the high standards required in industries such as medical devices, electronics, and precision engineering. By offering clean, consistent, and robust welds, precision micro-welding stands out as an indispensable solution in modern manufacturing.

Why Choose Precision Micro Welding?

Precision micro-welding addresses challenges associated with traditional methods, such as thermal damage and a lack of control. Its ability to weld at the micron level makes it indispensable for industries requiring intricate assemblies. Unlike conventional techniques, it excels in maintaining the structural and aesthetic integrity of components, even when working with complex or delicate designs.

This technology is particularly suited for materials like thin metals, precious alloys, and intricate composites. Its versatility ensures the durability of welds while maintaining minimal waste and a reduced environmental impact, making it a sustainable choice for forward-thinking businesses.

Key Applications of Precision Micro Welding

Medical Technology: Precision micro-welding is critical for producing surgical tools, implants, and other devices where biocompatibility and ultra-fine assembly are paramount. The accuracy of this process ensures patient safety and device reliability.

Electronics Manufacturing: Micro-welding enables the assembly of delicate electronic components, including connectors, microchips, and sensors. Its high precision ensures reliable connections without compromising the functionality of the smallest parts.

Precision Engineering: From thermosensors to intricate industrial components, precision micro-welding is widely used to create high-strength joints with minimal material disruption, even in challenging environments.

Tool and Die Repair: Precision micro-welding plays a vital role in restoring worn or damaged tools and dies across engineering and manufacturing sectors. This process allows for precise repairs to critical areas, extending the life of components, reducing downtime, and lowering replacement costs. It’s an essential solution for maintaining operational efficiency in engineering plants and manufacturing facilities.

The Science Behind Precision Micro Welding

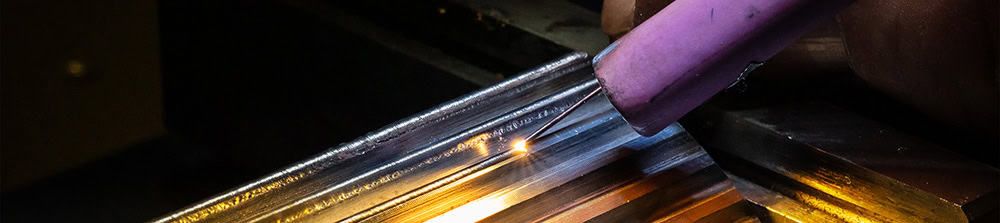

Precision micro-welding relies on focused laser beams that deliver high-energy density in a controlled manner. Unlike traditional methods, where excessive heat can cause warping or deformation, the laser’s concentrated energy melts only the desired area. This approach creates a clean, reliable joint without damaging surrounding material.

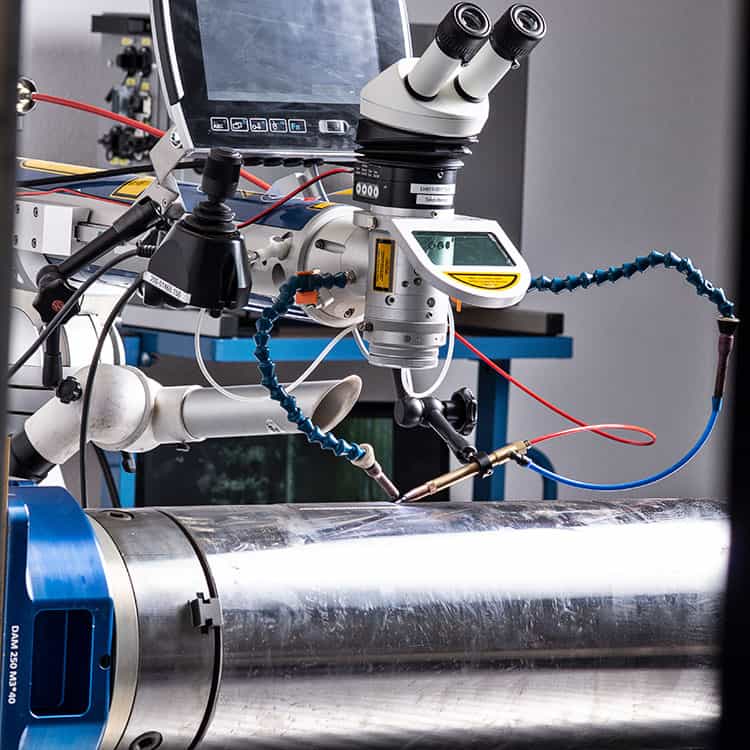

The technology incorporates real-time monitoring systems, ensuring that weld depth, consistency, and alignment meet stringent industry standards. These features are particularly advantageous in applications where micro-level accuracy is essential, such as medical implants or aerospace components. By adjusting parameters like pulse duration and beam intensity, micro welding offers unparalleled adaptability to different materials and welding requirements.

The Benefits of Precision Micro Welding

Unmatched Accuracy: Laser micro-welding provides pinpoint precision, allowing for intricate designs and high-strength joints. This accuracy is critical in fields where even minor deviations can result in failures or inefficiencies.

Minimal Thermal Distortion: By focusing heat only where it is needed, this process preserves the surrounding material’s structural integrity. This is particularly advantageous for delicate assemblies or temperature-sensitive components.

Environmental and Cost Efficiency: Unlike traditional welding methods, laser micro welding eliminates the need for consumables such as filler metals or flux. Additionally, it reduces material waste, making it both an environmentally friendly and cost-effective solution.

TLM Laser Solutions for Precision Micro Welding

At TLM Laser, we collaborate with Alpha Laser, a leader in advanced laser welding systems, to deliver state-of-the-art solutions tailored to your specific needs. Our systems are designed to handle intricate welding tasks with ease and precision. These systems are engineered for versatility, enabling seamless integration into existing production lines or as standalone solutions.

From medical device manufacturing to electronics assembly, our solutions redefine what’s possible in precision micro-welding. Contact our team today to explore how we can transform your welding processes.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.