Laser Engraving Explained

Laser engraving is a high-precision, versatile, and durable method of creating permanent marks or designs by removing material layers. Unlike laser marking, which alters the surface, engraving penetrates deeper into the material for enhanced durability and visibility, even in harsh conditions. This technology is widely used across industries such as aerospace, automotive, and medical manufacturing, where precision and reliability are essential.

What Is Laser Engraving?

Laser engraving is a subtractive process that vaporises layers of material to create permanent marks. By focusing a high-powered laser beam, it removes precise amounts of material, leaving behind smooth and sharply defined engravings. This process offers unparalleled precision and repeatability, ensuring consistent results for industrial, artistic, or personal applications.

Laser engraving is distinct from laser marking in that it physically removes material rather than altering it. This makes it ideal for applications requiring deeper, highly visible, and long-lasting marks.

Laser Engraving vs. Laser Marking

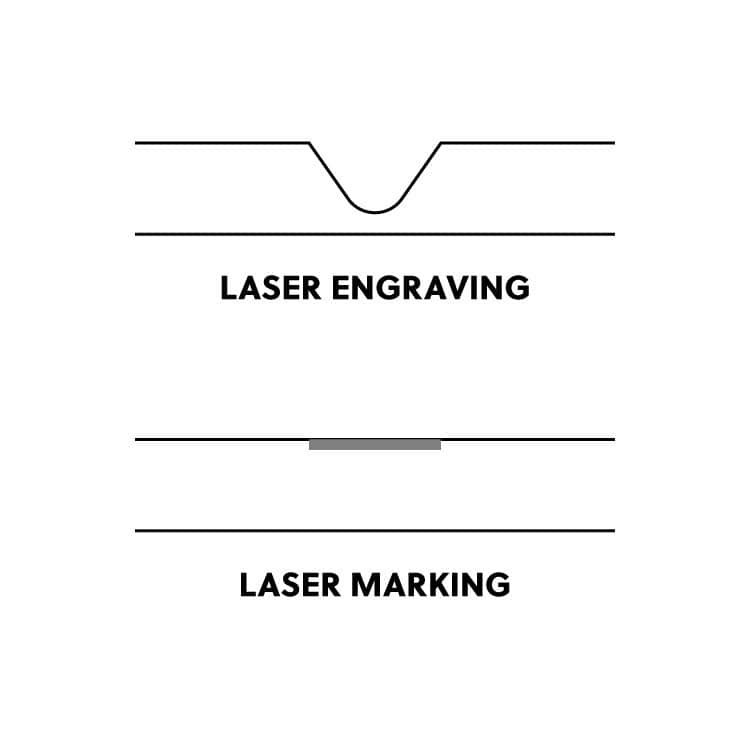

While laser engraving and marking are often used interchangeably, they differ significantly in their processes and outcomes:

Laser Engraving: Removes material to create a recessed mark, resulting in a deeper and more tactile imprint. This process uses high-intensity laser pulses to remove material layer by layer, creating a tactile imprint. It is commonly used in automotive and aerospace industries, where marks must endure extreme conditions.

Laser Marking: Alters the surface of a material by discolouration, oxidation, or annealing, leaving the surface intact. Ideal for applications requiring smooth, non-invasive markings, such as medical devices or electronics.

The Science Behind Laser Engraving

Laser engraving works through the physical removal of material via intense laser energy. This energy is focused into a narrow beam, generating heat that vaporises the material on contact. The depth of the engraving can be adjusted by controlling the laser’s power, speed, and focus, allowing for customisation based on application needs.

This process is highly efficient, eliminating the need for consumables or secondary operations. Additionally, it ensures high repeatability and precision, even on challenging surfaces or complex designs.

Advanced Laser Engraving Techniques

Laser engraving offers a variety of specialised methods to meet diverse industry demands. These advanced techniques extend the capabilities of traditional laser engraving, enabling intricate designs, improved surface quality, and enhanced functionality.

Deep Engraving: Deep laser engraving involves the removal of multiple layers of material to achieve significant depth. This technique is particularly useful for creating durable moulds, embossing tools, and dies. The depth of the engraving ensures that markings remain clear and legible even after prolonged use or exposure to harsh conditions. It is especially beneficial for applications in industries like automotive, aerospace, and tool manufacturing, where durability and precision are paramount.

Micro Engraving: Micro laser engraving delivers unmatched precision on a minute scale, producing finely detailed markings that are often visible only under magnification. This capability makes it essential for industries requiring intricate, filigree structures, such as jewellery design, watchmaking, and medical device manufacturing. The process ensures ultra-fine details with exceptional clarity, making it suitable for engraving logos, serial numbers, and microscopic patterns.

Laser Smoothing: Laser smoothing is employed to refine the surface quality of engraved areas, improving both their aesthetics and functionality. This technique reduces surface roughness, thereby extending the lifespan of tools and enhancing their performance. It is especially valuable for manufacturing and stamping processes, where smooth surfaces are essential for optimal results. By refining the engraved areas, laser smoothing enhances bonding or sealing performance and ensures durability in demanding environments.

Matting (Frosting): Laser matting, also known as frosting, creates a matte finish by altering the surface texture of the material. This method is widely used to achieve decorative effects or functional finishes, such as reducing glare or improving grip. Often applied to embossing tools or directly onto finished products, matting enhances the visual appeal and usability of the surface. Typical applications include frosted effects on glassware, textured finishes on metal surfaces, and light-diffusing patterns.

Benefits of Laser Engraving

Durability: Creates deep, long-lasting marks that withstand wear, abrasion, and environmental factors.

Precision: Delivers high-resolution engravings with unmatched detail.

Eco-Friendly: A chemical-free process that reduces waste and eliminates the need for consumables.

Versatility: Compatible with various materials, including metals, plastics, ceramics, and wood.

Cost-Effective: Reduces downtime and operational costs by minimising maintenance and consumable requirements.

Why Choose TLM Laser Engraving?

Laser engraving offers unmatched quality, precision, and versatility, making it the ideal choice for applications requiring permanent markings or decorative designs. Whether you’re producing high-volume industrial parts or customising unique items, laser engraving ensures reliable and efficient results every time.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.