Laser Hardening Explained

Unlock the potential of advanced laser technology with Laser Surface Hardening. This process enhances the durability and performance of metal components by delivering precise, efficient, and environmentally friendly heat treatment solutions. Ideal for industries requiring superior wear resistance and minimal distortion, laser surface hardening redefines precision engineering.

Revolutionising Heat Treatment

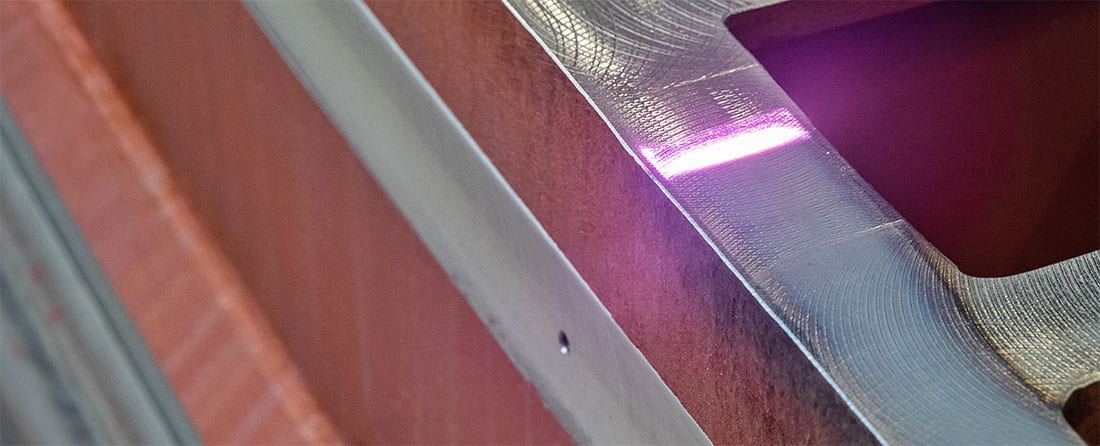

Laser surface hardening is a cutting-edge process designed to enhance the durability and performance of metallic components. By using a focused laser beam as a heat source, this technology rapidly heats the material’s surface to a precise temperature between 900°C and 1300°C, triggering a metallurgical transformation. The surrounding material acts as a natural heat sink, enabling self-quenching without the need for additional cooling methods like oil or water. This clean and efficient process ensures precise hardening with minimal environmental impact.

The Science Behind Laser Hardening

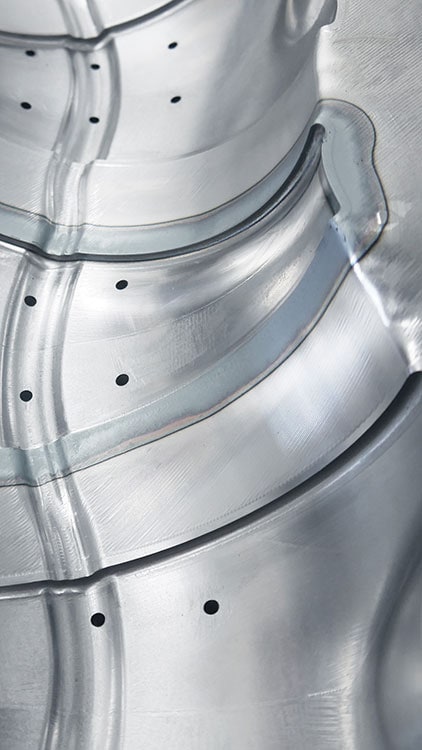

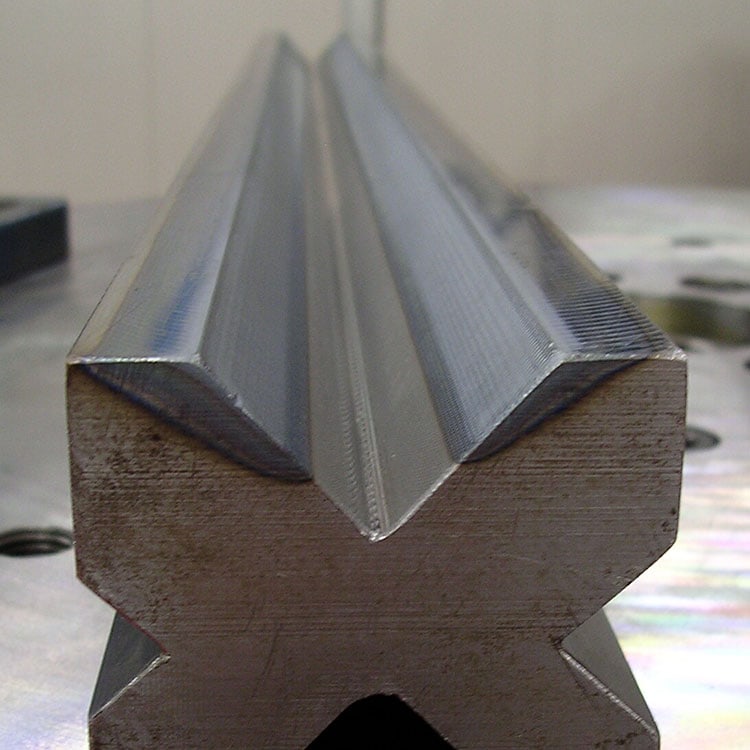

At the heart of laser surface hardening lies the process of metallurgical transformation. When the material’s surface is heated rapidly by the laser, its structure changes at the molecular level. The high temperatures lead to the formation of martensite, a hard crystalline structure that significantly increases the material’s wear resistance and fatigue strength. Unlike traditional methods such as flame or induction hardening, the focused laser beam delivers pinpoint accuracy, ensuring only the intended areas are hardened while maintaining the integrity of surrounding materials.

This precision makes laser hardening ideal for complex geometries, thin components, and intricate designs, eliminating the risk of warping or distortion. Additionally, the high-energy efficiency of lasers reduces processing times, making it suitable for high-volume industrial applications.

Comparing Hardening Technologies

Laser hardening stands out when compared to traditional methods like flame hardening and induction hardening:

1. Flame Hardening:

- Benefits: Precision, minimal heat-affected zones, and suitability for complex designs.

- Drawbacks: Higher initial investment costs but compensated by long-term efficiency.

2. Induction Hardening:

- Benefits: Simplicity and suitability for large, straightforward surfaces.

- Drawbacks: Inconsistent results, potential for warping, and slower processing times.

3. Laser Hardening:

- Benefits: Fast heating and suitability for repetitive production.

- Drawbacks: Limited flexibility for intricate geometries and higher energy costs.

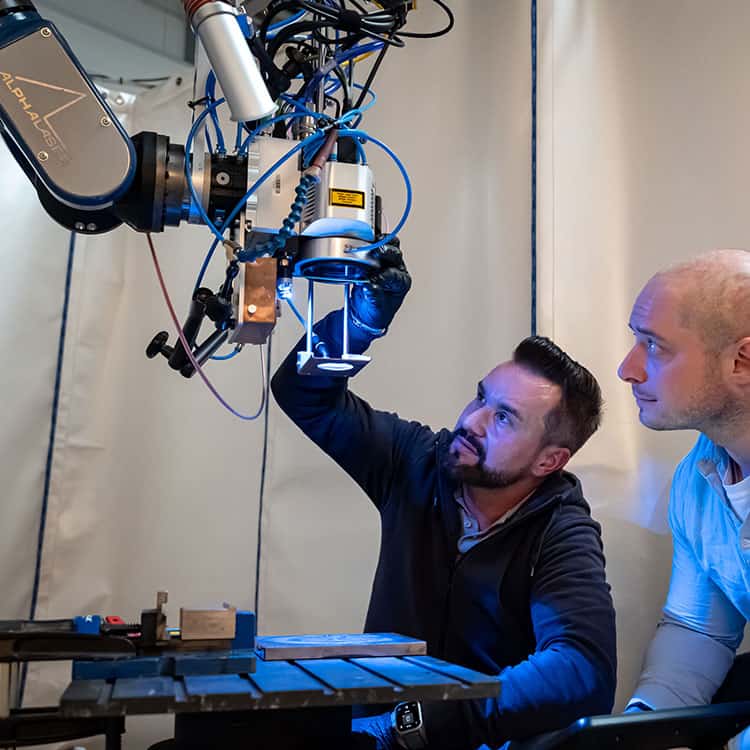

The AL-ROCK Mobile Laser System

The AL-ROCK mobile laser system represents the pinnacle of laser hardening technology. Designed for mobility and flexibility, this system enables on-site hardening of large and heavy components, such as casting moulds, without disrupting production workflows. With its 4 kW laser capacity, the AL-ROCK delivers targeted, high-quality hardening for applications requiring maximum precision.

Why Choose Laser Surface Hardening?

Laser surface hardening offers unmatched control, precision, and efficiency, making it the preferred choice for industries ranging from automotive to aerospace. Its ability to harden components without distortion or environmental harm positions it as a sustainable alternative to traditional methods. By investing in this advanced technology, businesses can achieve longer component lifespans, reduced maintenance costs, and enhanced operational efficiency.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.