Precision Laser Cutting Explained

Achieve intricate designs and precise cuts on natural and synthetic materials with Universal Laser Systems. Tailored for delicate applications, our laser systems provide unparalleled accuracy and versatility across industries like medical, automotive, and consumer goods.

Why Choose Universal Laser Systems for Organic Cutting?

Universal Laser Systems (ULS) excels in precision cutting for organic materials, offering advanced CO2 laser systems designed to handle delicate and challenging applications. Unlike traditional cutting methods, ULS systems utilise non-contact laser technology to deliver consistent results without damaging sensitive materials.

Whether working with textiles, leather, wood, or paper-based products, ULS machines deliver clean edges, reduced material waste, and high repeatability, ensuring a professional finish every time. With decades of experience and patented technologies, Universal Laser Systems sets the standard for precision organic cutting.

Applications of Precision Organic Cutting

Universal Laser Systems’ advanced CO2 laser technology is transforming precision cutting in various industries, particularly the medical and electronics sectors. By delivering clean and accurate results, ULS systems cater to the strict demands of these high-tech industries.

Gasket and Seal Manufacturing: A wide range of industries from automotive and aerospace to petrochemical and energy use laser cutting machines for the production of gaskets, oil seals and mechanical seals.

Medical Device Manufacturing: Laser cutting is ideal for producing intricate components such as surgical masks, medical filters, and flexible diagnostic equipment. The precision ensures clean edges on delicate materials like woven textiles or medical-grade plastics, meeting stringent hygiene and performance requirements.

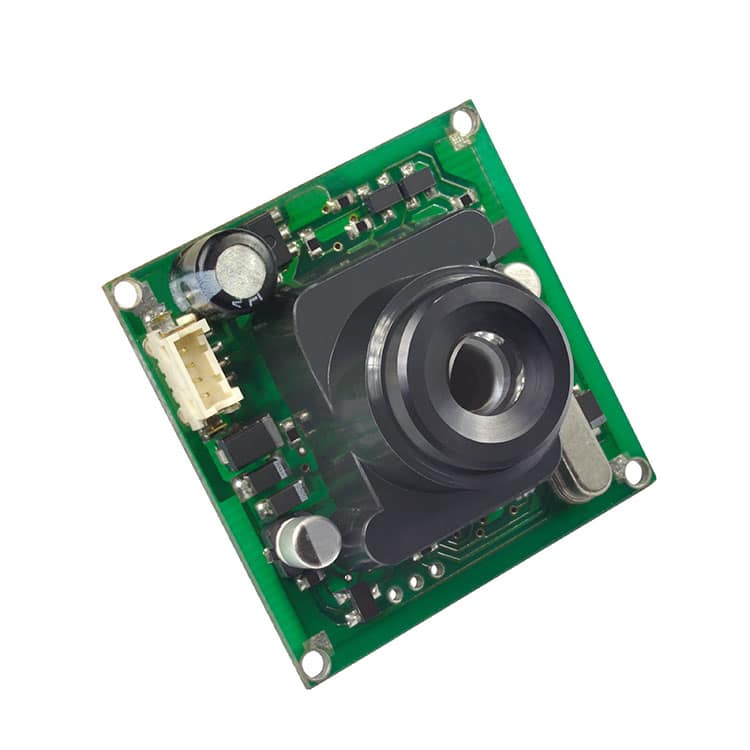

Electronics Manufacturing: ULS systems are frequently employed to cut and shape insulating films, flexible printed circuit boards (FPCBs), and other organic materials used in electronic devices. The non-contact process eliminates mechanical stress, ensuring the integrity and functionality of these critical components.

Biomedical Applications: The ability to cut biodegradable materials with precision makes ULS lasers a valuable tool in creating eco-friendly medical products like dissolvable implants or drug delivery patches.

The Science Behind Organic Laser Cutting

Organic laser cutting with Universal Laser Systems utilises CO2 lasers, which operate by directing a concentrated beam of infrared light onto the material’s surface. The laser’s energy heats the material to the point of vaporisation, creating a precise cut without physical contact.

CO2 lasers are particularly effective for organic materials due to their absorption properties. Materials like wood, leather, and textiles efficiently absorb the laser’s wavelength, resulting in clean, precise cuts with minimal heat-affected zones. This process also eliminates mechanical stress on the material, preserving its integrity and appearance.

Advanced features, such as Universal’s Multi-Wavelength Technology, optimise the laser’s performance across a wide range of organic materials. By adjusting the wavelength and power, ULS systems achieve precision cutting tailored to the unique properties of each material.

Benefits of Precision Organic Cutting with ULS

Unmatched Precision

ULS systems ensure every cut meets exacting specifications, ideal for applications requiring intricate designs and high tolerances.

Versatility Across Materials

From soft fabrics to dense woods, ULS lasers handle a variety of organic materials with ease, providing consistent performance across different industries.

Non-Contact Process

The non-contact nature of laser cutting eliminates wear and tear on tools, reduces material waste, and prevents damage to delicate materials.

Eco-Friendly Cutting

Laser cutting produces minimal waste and requires no consumables like blades or dies, aligning with sustainability goals in modern manufacturing.

Customisation and Automation

ULS systems integrate seamlessly into production lines, offering customisation options to meet unique business needs while automating repetitive tasks for higher efficiency.

TLM Laser and Universal Laser Systems: Your Organic Cutting Experts

At TLM Laser, we are proud to partner with Universal Laser Systems, delivering cutting-edge solutions for precision organic cutting. Our expertise in ULS technology ensures that businesses can optimise their processes, reduce costs, and enhance product quality.

Whether you’re crafting intricate patterns in textiles or producing high-end leather goods, TLM Laser and ULS provide the tools you need to excel. Contact us today to discuss your cutting requirements and discover how ULS systems can transform your operations.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.