Tyre Manufacturing

Laser cleaning technology has become a vital tool in the tyre manufacturing industry, revolutionising mould maintenance and surface preparation. By using precision laser energy to remove contaminants from production tools, manufacturers can achieve cleaner moulds, improved rubber flow, and reduced production defects. This non-abrasive method preserves the integrity of mould surfaces, extends equipment life, and minimises production downtime.

Applications of Laser Cleaning in Tyre Manufacturing

Laser cleaning plays a critical role at multiple stages of tyre production, ensuring consistency and quality while reducing manual maintenance efforts. Some of the key applications include:

Mould Cleaning and Maintenance

Tyre moulds accumulate rubber residues and other contaminants over time, leading to inconsistencies in rubber flow and surface defects on finished tyres. Laser cleaning systems, such as the JETLASER from 4JET, offer a non-contact cleaning method that effectively removes these residues without damaging the precision details of the mould. This ensures a longer mould lifespan and reduces the need for frequent replacements.

Production Tool Cleaning

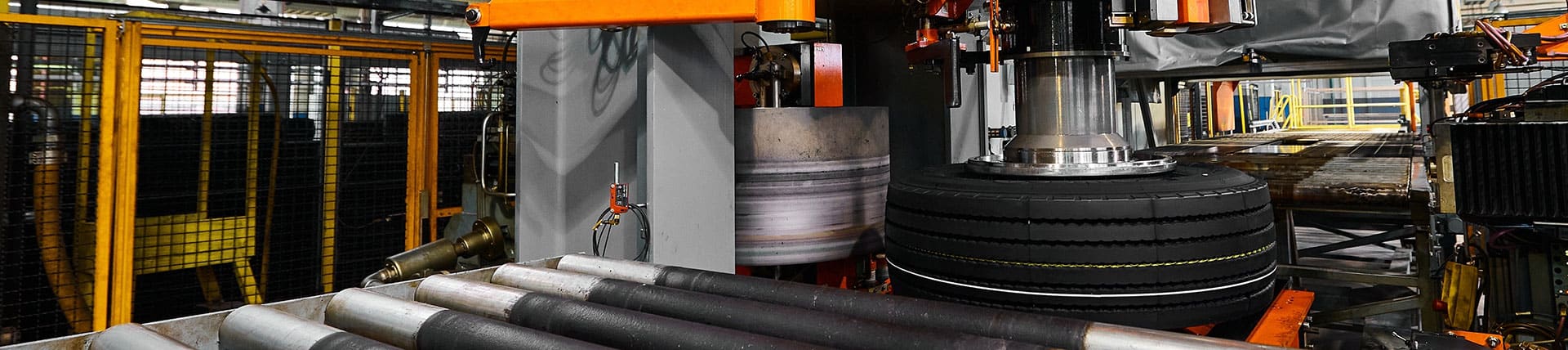

Beyond tyre moulds, laser cleaning is utilised for the maintenance of other production tools such as drum assemblies, curing tools, and rollers. This prevents contaminant build-up that could affect production efficiency and quality.

The Science Behind Laser Cleaning for Tyre Manufacturing

Laser cleaning works by directing a focused laser beam onto the surface of a material, where it interacts with contaminants. The laser energy is absorbed by the unwanted material, causing it to break down and vaporise or detach from the surface without damaging the underlying substrate.

This process relies on the principle of ablation, where the laser’s energy threshold is carefully calibrated to affect only surface contaminants while preserving the mould material. The result is a dry, chemical-free cleaning method ideal for sensitive components.

The JETLASER from 4JET uses a specialised pulsed laser designed for tyre manufacturing environments. The high peak energy and short pulse durations effectively break down organic and inorganic residues, ensuring thorough cleaning with minimal heat impact on the mould surface.

Key Benefits of Laser Cleaning in Tyre Production

Non-Abrasive Cleaning

Traditional cleaning methods such as blasting or chemical treatments can wear down the fine details of tyre moulds over time. Laser cleaning, however, is a non-contact, non-abrasive process, preserving the integrity of the mould while still achieving a deep clean.

No Chemicals or Abrasive Media Required

Laser cleaning eliminates the need for hazardous chemicals, abrasive media, or consumables often associated with other cleaning methods. This makes it a dry, eco-friendly solution that reduces operational costs and minimises waste.

Consistent and Reliable Results

The precision of laser technology ensures a uniform cleaning effect across the entire surface of the mould or tool, reducing the risk of inconsistencies in the final tyre product. Laser systems can be programmed for repeatable results, enhancing quality control in production.

Reduced Downtime and Maintenance

The JETLASER system is designed for fast, in-situ cleaning, allowing tyre moulds and production tools to be cleaned without disassembly. This capability significantly reduces downtime and allows for more frequent cleaning cycles, preventing long-term build-up of contaminants.

Safer and Cleaner Work Environment

Without chemicals or abrasive materials, laser cleaning contributes to a safer working environment for staff while reducing waste disposal challenges. The compact, enclosed design of systems like the JETLASER makes them suitable for harsh manufacturing environments.

TLM Laser Solutions for Tyre Manufacturing

At TLM Laser, we are proud to offer advanced laser cleaning systems from 4JET, including the JETLASER series, designed specifically for the tyre manufacturing industry. These systems provide unmatched performance for tyre mould cleaning, surface preparation, and sidewall marking applications.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.