Laser Cladding Information

Laser cladding is a high-precision process used to enhance surface properties, improving wear resistance and extending component life. By applying a controlled layer of material, it enables repair, refurbishment, and performance improvements for critical parts.

Learn about our applications

Laser Cladding

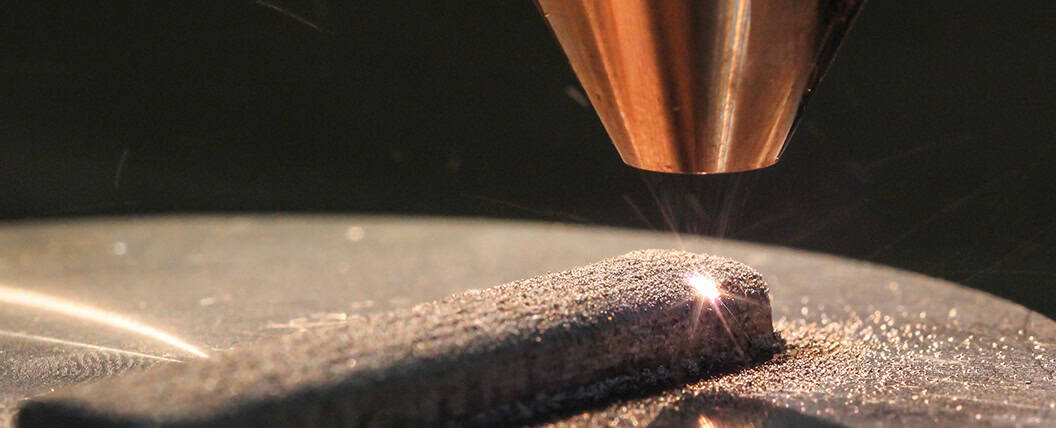

Laser cladding is the deposition of material onto a base part for the purpose of enhancing the mechanical properties of the component.

Direct Metal Deposition (DMD) uses a laser to melt metal powder or wire onto a workpiece, creating a metallurgically bonded coating. This process is frequently used for component restoration, surface hardening, and prototyping, particularly in industries like aerospace, automotive, and medical device manufacturing. Systems with the capability to deposit material with pinpoint accuracy are ideal for both part repair and functional surface enhancement, offering increased lifespan and performance for critical components.

Talk to Us!

Connect with our Technical & Support Team.