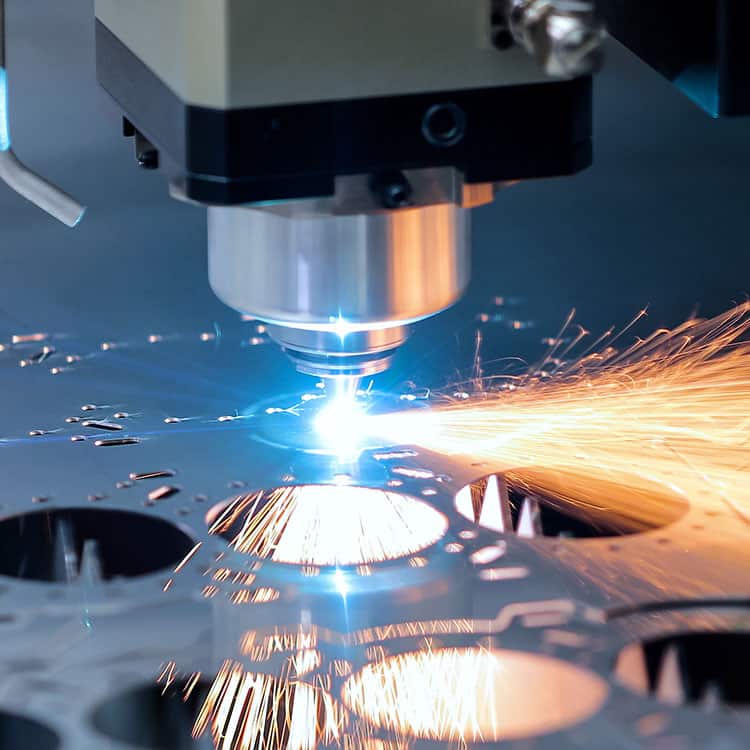

Laser Cutting Gaskets & Seals

Laser cutting has become a highly effective solution for manufacturing gaskets and seals, offering unparalleled precision, efficiency, and flexibility compared to traditional cutting methods. This advanced technology ensures clean, accurate cuts even for intricate designs, making it ideal for industries where tight tolerances and material integrity are critical.

How Laser Contaminant Removal Works

Laser cutting for gaskets and seals involves a focused laser beam that generates intense heat to ablate the material along a pre-defined path. The laser’s precision allows it to create clean edges with minimal heat-affected zones (HAZ), preserving the integrity of the gasket material.

Key Laser Types for Gasket Cutting:

- Ultraviolet (UV) Lasers: Used for micro-cutting applications where fine detail is required.

- CO₂ Lasers: Ideal for organic and non-metallic materials like rubber, silicone, and PTFE.

- Fibre Lasers: Suitable for cutting thin metallic seals and reflective materials.

Why Laser Cutting Excels for Gaskets:

- Non-Contact Cutting: Eliminates tool wear and mechanical stress on the material.

- Clean Edges: The heat from the laser slightly melts the edges, resulting in a smooth, sealed finish that prevents fraying or contamination.

- Minimal Heat Impact: Advanced beam control ensures low heat input, reducing the risk of warping.

The precision and control offered by laser technology make it the preferred choice for gasket production, especially when working with materials that require high tolerances and minimal waste.

Applications of Laser Cutting for Gaskets and Seals

Laser cutting technology is widely used across various industries to create gaskets and seals that meet stringent quality standards. Some of the primary applications include:

Automotive Gaskets and Seals

Laser cutting enables the production of high-precision gaskets for automotive engines, fuel systems, and exhaust systems. The ability to cut heat-resistant and chemically stable materials like silicone, graphite, and PTFE ensures durability under extreme operating conditions.

Aerospace Components

In the aerospace sector, where every component must meet exacting standards, laser cutting is used to create lightweight yet durable seals for fuel tanks, hydraulic systems, and insulation barriers. The precision offered by laser systems ensures minimal material waste and perfect fitment.

Industrial Machinery and Manufacturing Equipment

Laser cutting is essential in producing seals and gaskets for pumps, compressors, and heavy machinery. These components often require custom shapes and materials like EPDM, neoprene, and fibre composites, which can be precisely cut using laser technology.

Electronics and Electrical Components

The electronics industry requires micro-sized seals and insulation gaskets with intricate geometries. Laser cutting delivers the accuracy needed for these delicate components while ensuring no damage to sensitive materials.

Medical Seals and Gaskets

In medical device manufacturing, laser cutting is used to create gaskets and seals from biocompatible materials such as silicone and PTFE. These parts are essential in diagnostic equipment, fluid management systems, and surgical devices where hygiene and precision are critical.

TLM Laser Solutions for Gasket and Seal Cutting

At TLM Laser, we offer state-of-the-art laser cutting solutions specifically suited for gasket and seal manufacturing. Our partnerships with Universal Laser Systems and LasX ensure you have access to advanced CO₂ laser technology capable of handling a wide range of materials with exceptional precision.

Our Universal Laser Systems and LasX CO₂ laser platforms offer tailored solutions for non-metallic materials, while our Accurl Fiber Lasers are perfect for metallic seals. Whether you’re producing gaskets for automotive, aerospace, or medical industries, TLM Laser delivers cutting solutions that help you maintain quality, efficiency, and cost-effectiveness.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.