Laser Welding for the Tool & Die Industry

Extend the lifespan of your tools and dies with precision laser welding solutions. Reduce costs, minimise downtime, and achieve unparalleled accuracy in restoring industrial components.

Why Laser Welding for the Tool & Die Industry?

The tool and die industry is vital for producing components used across automotive, aerospace, and manufacturing sectors. These tools often face wear and damage due to high-pressure operations, leading to production disruptions and costly replacements. Laser welding provides a transformative solution by offering precision repairs, reducing material waste, and extending the lifecycle of tools and dies.

Unlike traditional methods, laser welding is non-invasive and precise, allowing for targeted material deposition. This ensures minimal heat distortion, preserving the tool’s original design and functionality. The ability to perform repairs in-situ also minimises downtime, making laser welding a practical and cost-efficient choice for industries relying on consistent production.

Key Applications of Laser Welding in the Tool & Die Industry

Laser welding addresses a range of critical needs in the tool and die sector, including:

Repair of Worn or Damaged Tools

Restore cutting edges, mould cavities, and other intricate areas with unparalleled precision, maintaining original dimensions and functionality.

Custom Tool Modifications

Modify tools for specific applications or upgrades without needing full replacements.

Preventive Maintenance

Conduct targeted repairs to address early signs of wear, extending the lifespan of essential equipment.

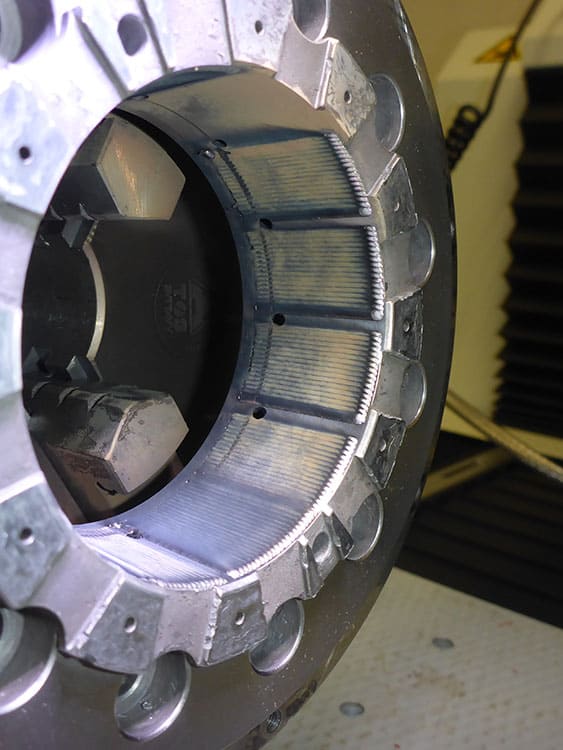

Restoration of Moulds and Dies

Reconstruct damaged areas of injection moulds, stamping dies, and extrusion tools, ensuring high-quality production standards.

Welding of Hard-to-Reach Areas

Employ fine laser beams to repair delicate or inaccessible sections of tools and dies.

The Science Behind Laser Welding in the Tool & Die Industry

Laser welding for the tool and die industry employs concentrated beams of light to create strong, precise welds. The process involves melting the base material and adding filler material with micron-level accuracy, ensuring seamless integration with the original structure. The high intensity of the laser minimises heat-affected zones (HAZ), reducing the risk of warping and maintaining the structural integrity of the component.

This technology excels at joining or repairing challenging materials such as tool steels, hardened alloys, and high-strength metals. The precise control over laser parameters allows operators to address intricate details in tools and dies, making it ideal for repairing micro-cracks, worn edges, and complex geometries.

Modern laser welding systems, such as those from Alpha Laser, incorporate advanced features like remote control and programmable settings. These innovations enhance efficiency and allow operators to perform repeatable, high-quality welds across multiple applications.

Key Benefits of Laser Welding for Tools & Dies

Cost Efficiency

Eliminate the need for costly replacements by restoring damaged tools with laser precision.

Extended Tool Lifespan

Targeted repairs minimise wear and extend the life of critical components.

Environmental Sustainability

Reduce material waste and support sustainable production practices by opting for repair over replacement.

High Precision

Achieve exact material deposition with minimal heat distortion, ensuring tools retain their original functionality.

Versatility

Repair a wide range of materials, including hardened steels, carbides, and exotic alloys.

Minimised Downtime

Perform repairs on-site or in-situ, reducing interruptions to production schedules.

TLM Laser Solutions for the Tool & Die Industry

At TLM Laser, we partner with Alpha Laser, a leader in precision welding systems, to deliver tailored solutions for the tool and die sector. Our advanced systems are designed to handle intricate repairs, enabling manufacturers to restore damaged tools and enhance productivity. Alpha Laser’s portable and stationary units provide unmatched flexibility, ensuring that you can address repairs wherever they are needed.

Our solutions combine precision, reliability, and cost-effectiveness to meet the unique demands of the tool and die industry. With TLM Laser, you can minimise downtime, reduce expenses, and maintain operational excellence with cutting-edge laser welding technology.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.