Laser Marking & Engraving for the Tool and Die Industry

Empower precision and durability in the tool and die industry with advanced laser marking and engraving solutions tailored to meet your production demands.

Laser Marking for the Tool and Die Industry

The tool and die industry operates in high-pressure environments where accuracy, traceability, and durability are essential. Laser marking and engraving provide unmatched precision for marking tools, dies, and moulds with information such as serial numbers, logos, and operational guidelines. Unlike traditional marking methods, laser technology offers a non-contact solution, ensuring the integrity of the tool or mould remains unaffected.

Laser marking is a key enabler for manufacturers to achieve compliance with industry standards, improve traceability, and enhance operational efficiency. With applications ranging from part identification to branding, laser technology seamlessly integrates into the fast-paced workflows of the tool and die sector.

Laser Marking Applications in the Tool and Die Industry

Laser marking and engraving systems deliver robust and versatile solutions for a wide array of applications in the tool and die industry, including:

Tool Identification

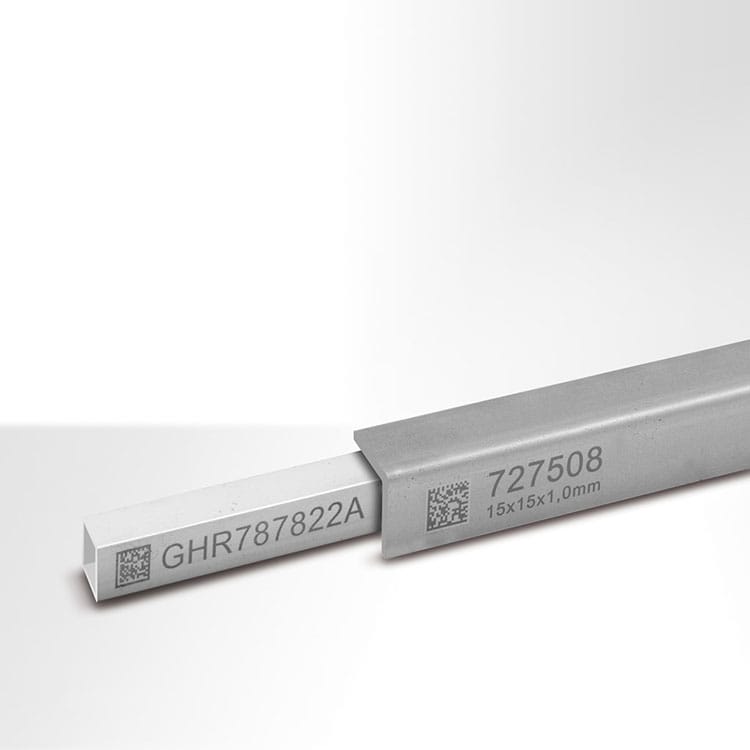

Properly identifying tools and components ensures they are used, maintained, and replaced correctly. Laser marking facilitates the precise engraving of part numbers, serial codes, and operational guidelines on each tool, reducing errors and boosting production efficiency. This is especially critical in industries that require regular audits or strict adherence to quality standards.

Mould Marking

Moulds are integral to manufacturing processes in various industries, and their accurate identification is essential. Laser engraving allows for permanent marking of cavity numbers, batch identifiers, and other details. This not only streamlines production but also reduces downtime caused by misidentification or missing information.

Die Engraving

Dies used for stamping or moulding require intricate and durable markings to maintain their functionality over time. Laser engraving provides a solution to create deep, permanent marks that withstand the intense pressures and repeated usage inherent in die applications.

Surface Functionalisation

Beyond identification, laser marking can alter surfaces for functional or aesthetic purposes. Textures or micro-engraved patterns can be added to enhance grip, improve material bonding, or create a decorative finish.

Material Traceability

The tool and die industry relies on complete traceability to ensure quality and compliance. Laser marking enables the application of 2D Data Matrix codes, barcodes, and QR codes, offering instant access to manufacturing data, maintenance history, and batch tracking.

These applications ensure that markings are clear, permanent, and resistant to wear, even under extreme industrial conditions.

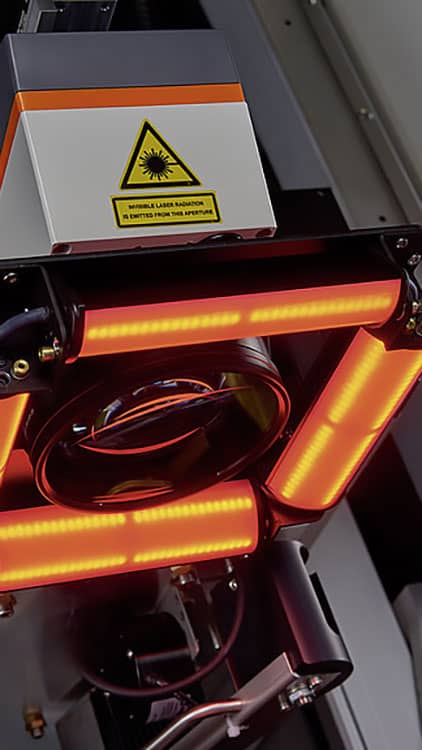

The Science Behind Laser Marking in the Tool and Die Industry

Laser marking employs a focused beam of light to precisely alter the surface of a material. The following processes are particularly effective for the tool and die sector:

Annealing

This technique creates high-contrast, oxidation-based marks on metals such as stainless steel, leaving the material’s surface intact. It is ideal for marking tools and dies where surface integrity is critical.

Engraving

Laser engraving removes material layers to create deep, permanent marks. This process is especially beneficial for moulds and dies, where markings must remain visible despite constant use and exposure to harsh conditions.

Ablation

Ablation involves removing surface layers, such as coatings or finishes, to expose the underlying material. This method ensures high-contrast markings and is often used in branding or component identification.

Black Marking

Through ultra-short laser pulses, black marking achieves extremely dark, high-contrast marks without damaging the material. This is particularly useful for tool steels and other reflective materials.

Each process can be tailored to meet specific material and operational requirements, ensuring consistent results across different applications.

Key Benefits

Laser marking and engraving offer numerous advantages for the tool and die industry:

Durability

Laser markings are resistant to wear, heat, corrosion, and chemicals. This ensures they remain legible throughout the lifecycle of the tool or component, even under extreme conditions.

High Precision

The accuracy of laser technology allows for intricate details and fine patterns to be marked on tools, moulds, and dies. This level of precision ensures consistency in production and improves the overall quality of end products.

Traceability

Permanent markings, such as serial numbers, batch identifiers, and barcodes, enable seamless tracking of tools and components. This enhances quality control, simplifies maintenance, and supports regulatory compliance.

Eco-Friendly

Laser marking eliminates the need for consumables such as inks or chemicals, reducing waste and supporting sustainable manufacturing practices. The process is clean, efficient, and requires minimal maintenance.

Customisation

Laser systems can be programmed to mark unique designs, company logos, or specific identifiers, meeting the diverse needs of manufacturers in the tool and die sector.

TLM Laser Solutions for the Tool and Die Industry

At TLM Laser, we provide cutting-edge laser marking systems in partnership with FOBA, designed to meet the rigorous demands of the tool and die industry. Our systems support a wide range of materials, including tool steels, ceramics, and composites, ensuring flexibility and reliability in every application.

Features like Intelligent Mark Positioning (IMP) and FOBA Mosaic ensure precise, repeatable marking without the need for complex fixtures, enhancing productivity and reducing waste. Whether for standalone systems or integrated production lines, TLM Laser offers tailored solutions that deliver efficiency and precision.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.