Laser Hardening for the Tool & Die Industry

Maximise the lifespan and performance of tools, moulds, and dies with Laser Hardening for the Tool & Die Industry. This advanced technology ensures precision, durability, and cost-efficiency, helping manufacturers maintain production quality while reducing downtime and wear-related expenses.

Laser Hardening for the Tool & Die Industry

The tool and die industry is critical to manufacturing, requiring components that withstand constant wear and tear while maintaining precision. Laser hardening offers an innovative solution to extend the lifespan of these tools, reducing the need for frequent replacements and repairs. By delivering targeted heat treatment, laser hardening enhances the surface durability of critical areas without affecting the base material.

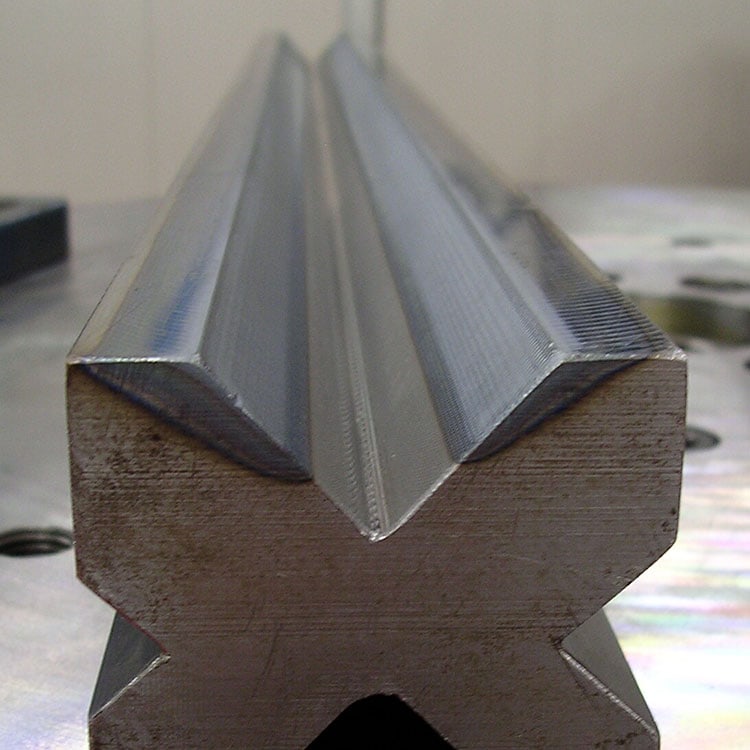

Unlike traditional methods such as flame or induction hardening, laser hardening allows for selective treatment of complex geometries, including intricate edges and surfaces. This precision ensures tools maintain their original dimensions and functionality, even under challenging production conditions.

Applications of Laser Hardening in Tool & Die Manufacturing

Laser hardening has transformed how tools and dies are maintained and optimised, offering unmatched precision for various applications:

Punching Dies: Harden specific wear zones like pinch edges and contact points, minimising distortion and improving cutting accuracy.

Cutting Tools: Improve the wear resistance of cutting edges, extending their operational life and reducing downtime for tool replacements.

Injection Moulds: Enhance the durability of sealing edges, closing surfaces, and radii, ensuring consistent moulding performance.

Deep Drawing Tools: Reinforce critical areas prone to wear, such as bending radii and contact surfaces, ensuring smooth operation under high loads.

The Science Behind Laser Hardening for Tool & Die

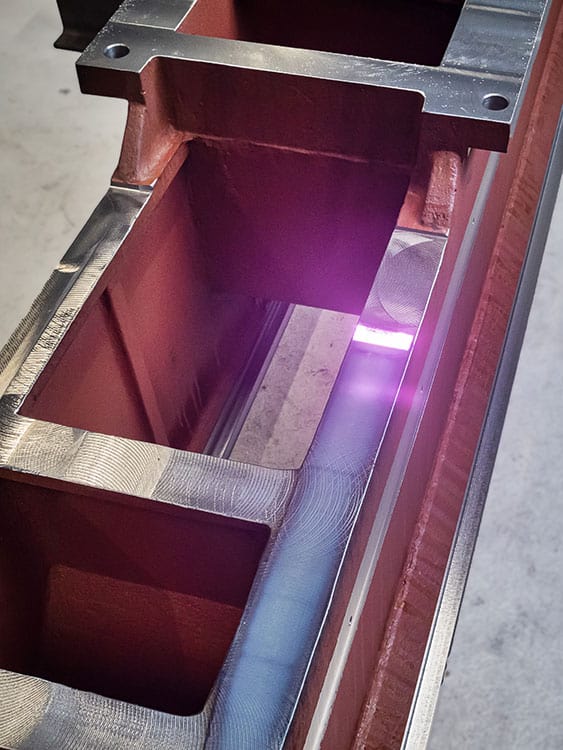

Laser hardening employs concentrated light to deliver controlled heat to the surface of a workpiece. By rapidly raising the temperature of the metal surface between 900°C and 1300°C, a hardened layer is formed through metallurgical transformation. This process, known as self-quenching, eliminates the need for additional cooling agents like oil or water, making it cleaner and more sustainable than traditional methods.

This targeted heat application allows for selective hardening of specific areas, ensuring that surrounding zones remain unaffected. Complex geometries and hard-to-reach areas, such as grooves and blind holes, can be treated with precision. This capability is particularly valuable for tool and die applications, where maintaining dimensional accuracy is essential.

Benefits of Laser Hardening for the Tool & Die Industry

Enhanced Wear Resistance: Prolongs the life of tools by strengthening high-stress areas.

Precision Treatment: Targets specific zones without affecting neighbouring surfaces or materials.

Minimal Distortion: Ensures tools retain their original shape and functionality after treatment.

Cost-Effectiveness: Reduces the need for frequent tool replacements, lowering long-term operational costs.

Sustainability: Eliminates the use of cooling oils or water, making it an environmentally friendly option.

TLM Laser Solutions for Tool & Die

At TLM Laser, we provide cutting-edge laser hardening and cladding solutions, including the Alpha Laser AL-ROCK mobile system. Designed to deliver precise, targeted treatment for tools and dies, the AL-ROCK ensures unmatched reliability and efficiency in industrial environments.

Our team works closely with you to integrate laser systems into your workflow, minimising downtime and maximising productivity. Whether you’re looking to enhance tool durability, repair worn components, or optimise your manufacturing process, TLM Laser has the expertise and technology to meet your needs.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.