Laser Cleaning for the Tool & Die Industry

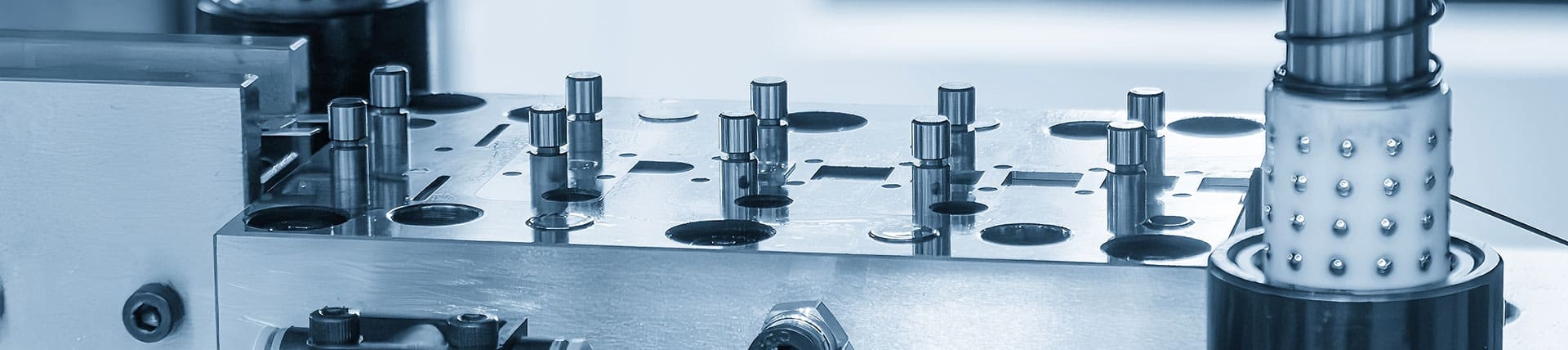

In the demanding tool and die industry, maintenance and surface preparation are critical for achieving high-quality production results. Laser cleaning offers a non-abrasive, eco-friendly solution for removing contaminants, restoring precision tools, and ensuring optimal die performance.

How Laser Cleaning Works

Laser cleaning utilises high-energy pulses of light to ablate contaminants like rust, residue, and coatings. The process heats the impurities, causing them to vaporise or detach from the surface, leaving the underlying material intact. This non-contact method ensures consistent and high-quality cleaning.

Applications of Laser Cleaning in the Tool & Die Industry

1. Mould and Die Cleaning

Laser cleaning removes residues such as mould release agents, burnt polymers, and carbon deposits from dies and moulds. The process preserves the surface texture and ensures dimensional accuracy, essential for high-quality production.

2. Surface Preparation for Coating and Texturing

Laser systems precisely clean and prepare tool and die surfaces for the application of coatings or textures, improving adhesion and extending the lifespan of the coating. This enhances the tool’s resistance to wear and corrosion.

3. Rust and Oxide Removal

Tools and dies exposed to harsh environments often develop rust and oxides. Laser cleaning eliminates these contaminants without damaging the substrate, restoring the tool’s functionality and extending its service life.

4. Cleaning Delicate Tooling

Intricate or sensitive tools benefit from laser cleaning’s precision, as it can target contaminants in hard-to-reach areas without risking damage to fine details or edges.

Benefits of Laser Cleaning for the Tool & Die Industry

1. Non-Abrasive and Precision Focused

Unlike abrasive methods such as blasting, laser cleaning preserves the integrity of tools and dies. It eliminates the risk of surface damage, ensuring dimensional accuracy and maintaining intricate details.

2. Increased Productivity

With its ability to clean tools quickly and efficiently, laser cleaning minimises downtime and enhances production throughput, making it an invaluable asset for the tool and die industry.

3. Environmentally Friendly

Laser cleaning eliminates the need for chemicals, solvents, or abrasive media, reducing waste and environmental impact. It aligns with the industry’s push toward sustainable manufacturing practices.

4. Cost-Effective Maintenance

By reducing the frequency of tool replacements and extending the lifespan of dies, laser cleaning offers long-term cost savings. It also streamlines maintenance, cutting down on labour and material costs.

Compliance with Industry Standards

Laser cleaning meets stringent industry standards for safety and environmental responsibility. Its dry, consumable-free process ensures consistent compliance with health and safety regulations in manufacturing environments.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.