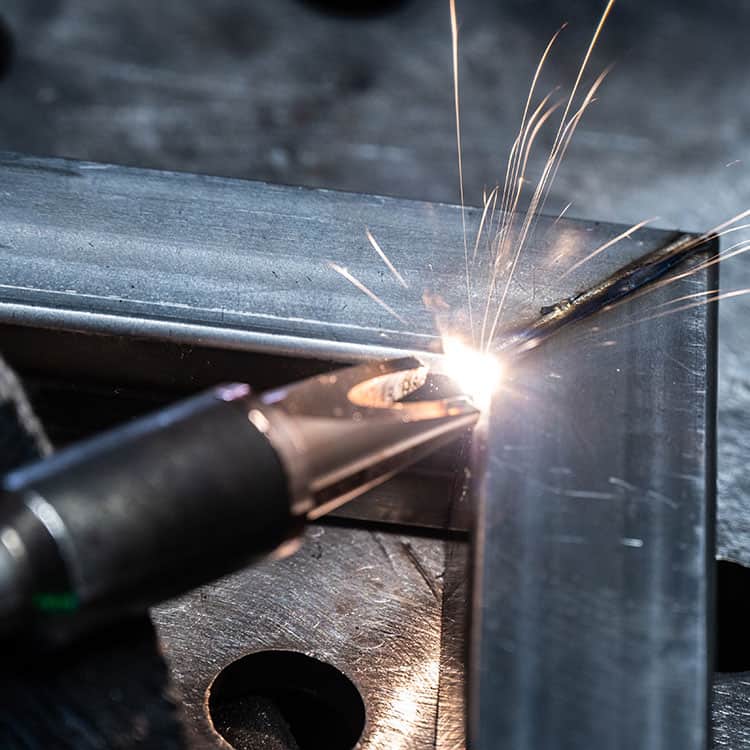

Laser Welding for the Rail Industry

Streamline rail manufacturing and maintenance with precision laser welding solutions. Deliver strong, reliable welds while minimising downtime and maximising operational efficiency.

The Importance of Laser Welding for the Rail Industry

The rail industry demands robust and durable components capable of withstanding heavy loads, extreme temperatures, and continuous wear and tear. Traditional welding methods often fall short when precision and efficiency are required in manufacturing and maintenance processes. Laser welding offers an innovative solution by providing unmatched accuracy, faster processing times, and minimal material distortion.

From repairing critical rail components to manufacturing high-strength parts, laser welding plays a pivotal role in ensuring the reliability and longevity of rail infrastructure. The versatility of laser technology allows for seamless integration into both production lines and field maintenance operations, ensuring consistency and quality.

Key Applications of Laser Welding in the Rail Industry

Laser welding has become indispensable for addressing diverse needs in rail manufacturing and maintenance, including:

Rail Component Fabrication

Ensure the precision and durability of vital components such as bogies, axles, and coupling systems with high-strength welds.

Track and Rail Repairs

Address wear and damage caused by heavy loads and environmental conditions, extending the service life of tracks and other infrastructure.

Manufacture of High-Strength Assemblies

Weld critical components with complex geometries, such as gearboxes and housings, ensuring they meet stringent safety standards.

Refurbishment of Rolling Stock

Perform detailed repairs on train bodies, doors, and interior components to restore functionality and aesthetics.

Thermosensor and Electronics Welding

Assemble temperature-sensitive devices and sensors used for monitoring rail operations with precision and minimal heat distortion.

The Science Behind Laser Welding in the Rail Industry

Laser welding in the rail industry relies on concentrated laser beams to achieve deep penetration and high-strength welds. The process begins with the precise delivery of laser energy to the joint, melting the base material and any filler metal to form a strong, homogeneous bond. This level of control ensures minimal heat-affected zones (HAZ) and reduces the risk of thermal distortion, making it ideal for thick materials and intricate assemblies.

Advanced laser systems, such as those provided by Alpha Laser, allow for the customisation of parameters like beam intensity, speed, and focus. This flexibility ensures consistent results across various rail components, from small electronics to large structural assemblies. Additionally, modern laser systems often incorporate automation and real-time monitoring, increasing efficiency and reducing the likelihood of defects.

Key Benefits of Laser Welding for Rail Applications

Durability

Laser welding produces high-strength, corrosion-resistant welds that withstand extreme conditions and heavy loads.

Precision

The focused beam allows for accurate welding of intricate components, ensuring minimal distortion and high-quality results.

Efficiency

Faster welding speeds and reduced preparation times improve productivity, enabling quicker project turnaround.

Versatility

Suitable for a wide range of rail components, from small electronics to large structural parts.

Cost-Effectiveness

Minimise material waste and reduce the need for post-weld finishing, resulting in long-term cost savings.

On-Site Repairs

Portable laser welding systems enable rapid field maintenance, reducing downtime and ensuring uninterrupted operations.

TLM Laser Solutions for the Rail Industry

At TLM Laser, we provide state-of-the-art laser welding solutions tailored to the rail industry’s unique challenges. Our partnership with Alpha Laser ensures access to cutting-edge systems capable of addressing both manufacturing and maintenance needs. From portable units for on-site repairs to advanced systems for automated production lines, our solutions are designed to maximise efficiency and reliability.

With TLM Laser, rail operators and manufacturers can benefit from enhanced durability, reduced downtime, and consistent performance across all welding applications. Our expert team works closely with clients to deliver customised solutions that meet the rigorous demands of the rail sector.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.