Laser Processing for the Rail industry

Precision and durability are essential in rail manufacturing and maintenance. TLM Laser provides advanced laser systems for marking, welding, cutting, and cleaning, helping manufacturers and operators produce high-quality components and maintain infrastructure to the highest standards.

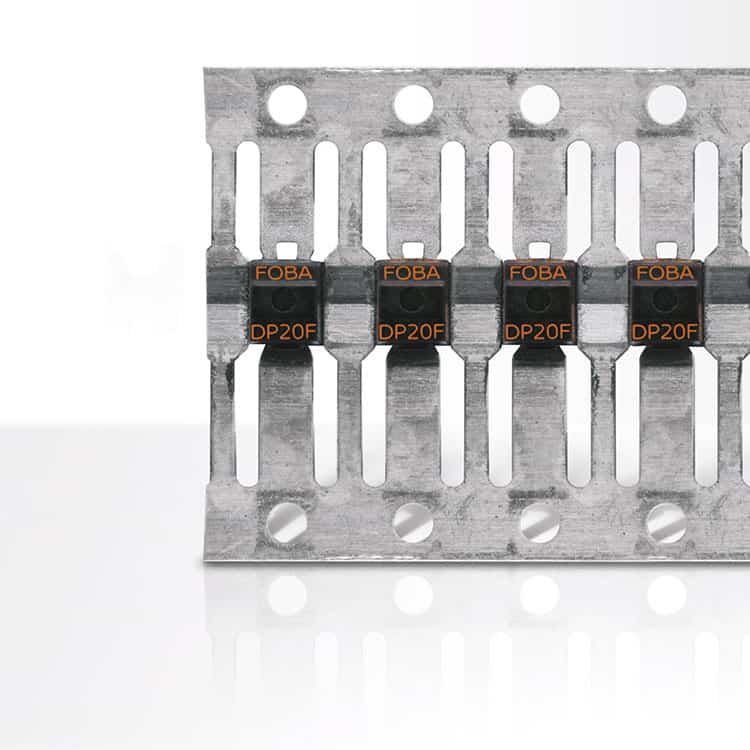

Durable Marking for Rail Infrastructure Components

TLM Laser supplies marking systems for rail components, ensuring permanent, high-contrast identification on metals and composites. These systems enable traceability, compliance with safety regulations, and clear branding on components like tracks, axles, and signalling equipment.

Precision Welding for Rail Equipment Assembly

Our laser welding systems help manufacturers create strong, reliable connections in rail infrastructure and components. From fabricating structural parts to assembling electronic housings, these machines deliver precise welds that ensure long-term performance under demanding conditions.

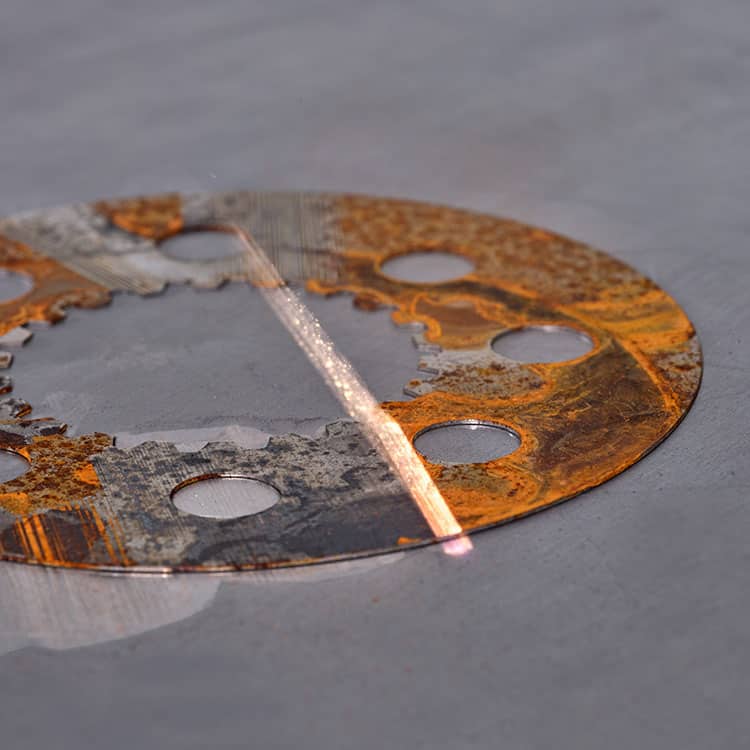

Non-Abrasive Cleaning for Rail Maintenance

TLM Laser offers cleaning systems designed to maintain and restore rail infrastructure. By removing rust, coatings, and contaminants from tracks, bridges, and other components, these systems support efficient maintenance and extend the service life of rail equipment.

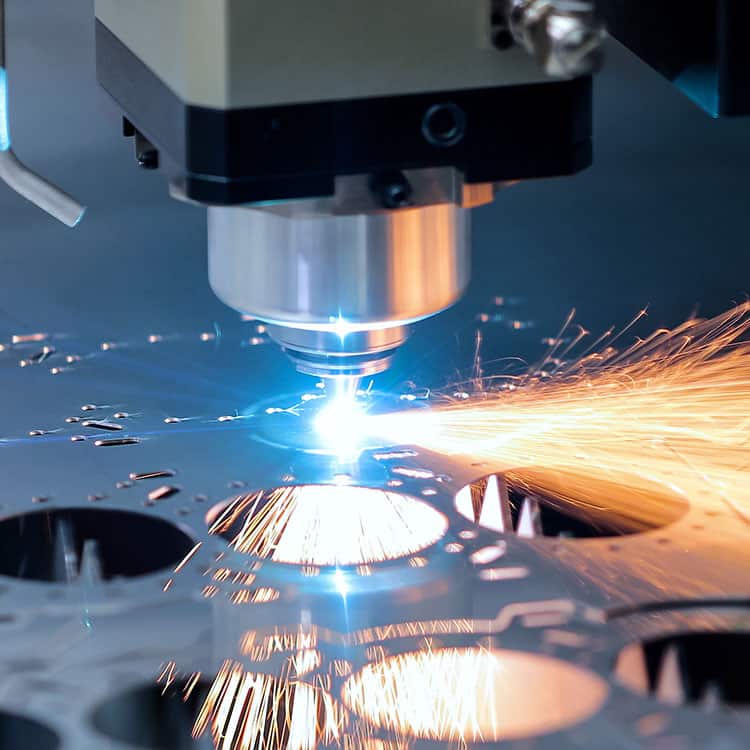

Cutting Structural Components for Rail Manufacturing

Our laser cutting systems enable the production of intricate and robust rail components. From helping with the shaping track sections to creating custom electronic housings, these machines ensure accuracy, efficiency, and quality in rail manufacturing processes.

Innovate with Confidence

Laser Machines and Systems

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.