Laser Marking & Engraving for the Packaging Industry

Discover how TLM Laser, in partnership with LasX, delivers high-quality, permanent laser marking and engraving solutions for traceability, branding, and regulatory compliance in the packaging industry.

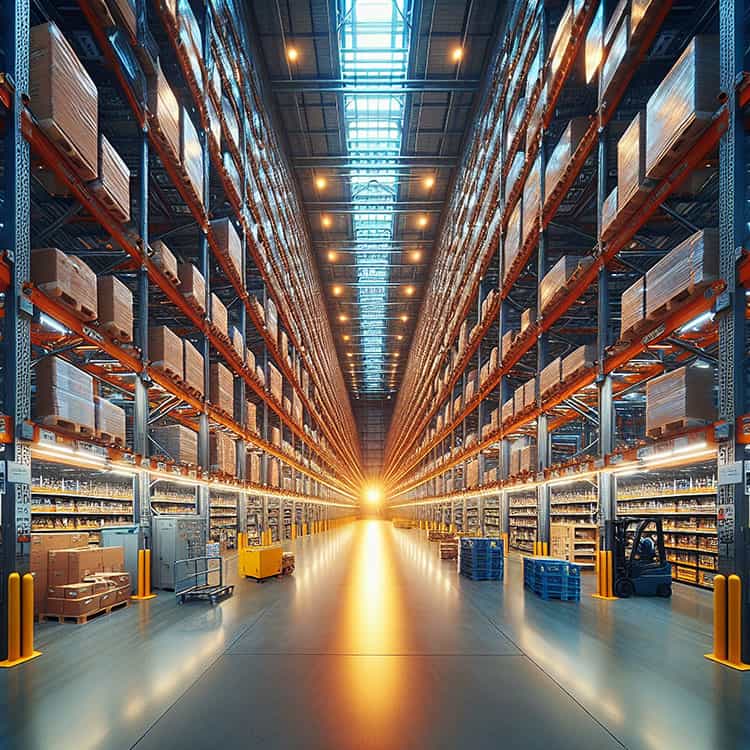

The Importance of Laser Marking for the Packaging Industry

In today’s competitive market, the packaging industry demands precise, permanent, and legible markings to address various needs, including branding, compliance, traceability, and anti-counterfeiting. Laser marking and engraving offer versatile solutions compatible with materials such as plastics, metals, cardboard, and glass. Unlike traditional printing methods, these laser processes are non-contact, chemical-free, and capable of producing high-contrast marks that endure throughout the product’s lifecycle.

Industries such as food, beverages, pharmaceuticals, and consumer goods benefit from the reliability of laser marking and engraving. The adaptability of these technologies ensures compliance with international standards, including ISO, FDA, and CE.

Laser Marking Applications in Packaging

1. Product Identification

Laser-marked serial numbers, batch codes, and production dates facilitate seamless supply chain traceability. This capability is crucial for sectors like food, beverage, and pharmaceuticals, where accurate identification can prevent recalls.

2. Branding and Design

High-resolution laser markings enable detailed logos, custom designs, and text, enhancing the visual appeal of packaging without the risk of fading over time.

3. Compliance and Certifications

Mandatory markings, such as CE marks, FDA approvals, and recyclability symbols, are applied with precision, ensuring packages meet regulatory standards across various markets.

4. Anti-Counterfeiting

Unique laser-etched codes and security patterns deter counterfeit packaging, safeguarding brand authenticity and maintaining consumer trust.

5. Sustainability Markings

Laser processes produce eco-friendly markings, reducing waste associated with consumables like inks or labels.

The Science Behind Laser Marking in Packaging

Laser marking and engraving utilise focused laser beams to induce thermal or photochemical reactions, altering the surface of packaging materials to create high-contrast marks. This precise method ensures minimal impact on the underlying material.

Different laser types are suited to specific materials:

- Fibre Lasers: Ideal for marking metals, including aluminium cans and foil packaging.

- CO₂ Lasers: Best for organic materials like cardboard, wood, and paperboard.

- UV Lasers: Highly effective for marking plastics, ensuring high contrast without surface damage.

Advanced vision systems enhance accuracy by automatically aligning marks, even on complex packaging shapes.

Key Benefits

Durability: Laser markings are resistant to wear, fading, and environmental conditions.

Eco-Friendly: Eliminates the need for consumables like ink or labels, reducing waste and operational costs.

Speed and Efficiency: Ideal for high-speed production lines, laser marking keeps up with modern packaging demands.

Non-Contact Process: Ensures no damage to delicate packaging materials.

Customisation: Flexible enough to create intricate designs or unique codes on demand.

TLM Laser Solutions for Packaging

In collaboration with LasX, TLM Laser offers state-of-the-art laser marking and engraving systems tailored to the packaging industry’s specific needs. Our solutions ensure precise, permanent markings on a variety of packaging materials, optimized for traceability, compliance, and branding.

With advanced vision systems and user-friendly software, our laser systems integrate seamlessly into your production line, enhancing efficiency and ensuring high-quality results.

By choosing TLM Laser and LasX, you invest in cutting-edge technology that meets the stringent demands of the packaging industry, ensuring your products stand out while complying with all necessary regulations.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.