Laser Welding for the Oil & Gas Industry

Optimise durability and safety in the oil and gas industry with precision laser welding solutions. Perfect for repairing critical components and enhancing performance in demanding environments.

The Importance of Laser Welding for the Oil & Gas Industry

The oil and gas industry demands robust, reliable solutions to maintain the integrity of equipment operating under extreme conditions. From high pressures and temperatures to corrosive environments, the components used in this sector must withstand extraordinary stress. Laser welding provides a transformative approach to component fabrication and repair, ensuring durability, precision, and long-term performance.

Unlike traditional welding methods, laser welding minimises heat-affected zones, reducing the risk of warping and material degradation. This precision is critical when working on high-value components, such as pipelines, shafts, and spindles, where even minor imperfections can lead to costly downtime or catastrophic failures.

Key Applications of Laser Welding in the Oil & Gas Sector

Laser welding finds numerous applications within the oil and gas industry, enhancing productivity and extending the lifespan of critical components:

Drill Components: Reinforce and repair drilling tools for extended durability in harsh environments.

Pipeline Repair: Seal cracks and strengthen joints in pipelines to prevent leaks and ensure long-term reliability.

Valve Components: Weld intricate valve assemblies with precision to maintain safety and performance in high-pressure systems.

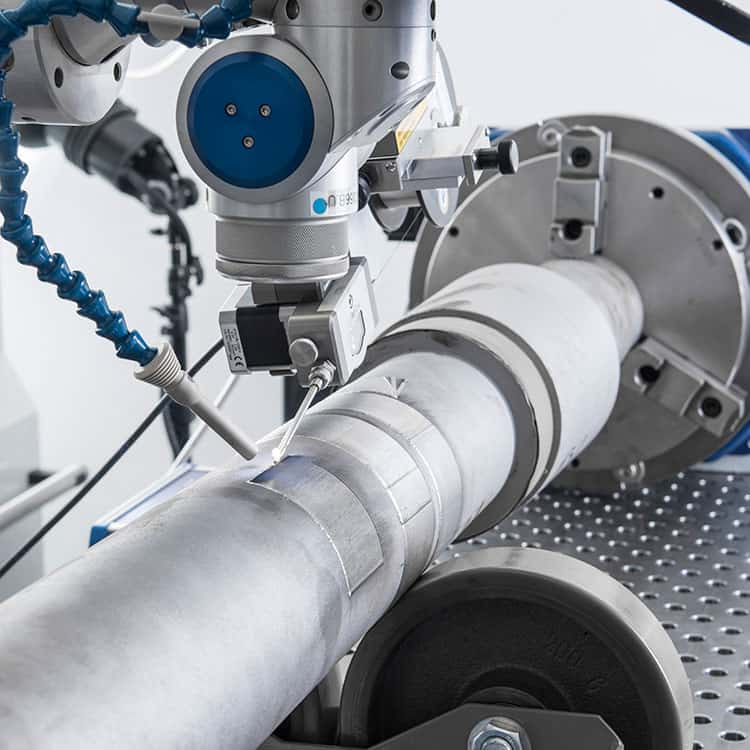

Spindles and Shafts: Restore worn or damaged spindles and shafts to optimal condition, reducing downtime and replacement costs.

Heat Exchangers: Repair and fabricate heat exchanger components with minimal distortion and maximum strength.

The Science Behind Laser Welding in Oil & Gas Applications

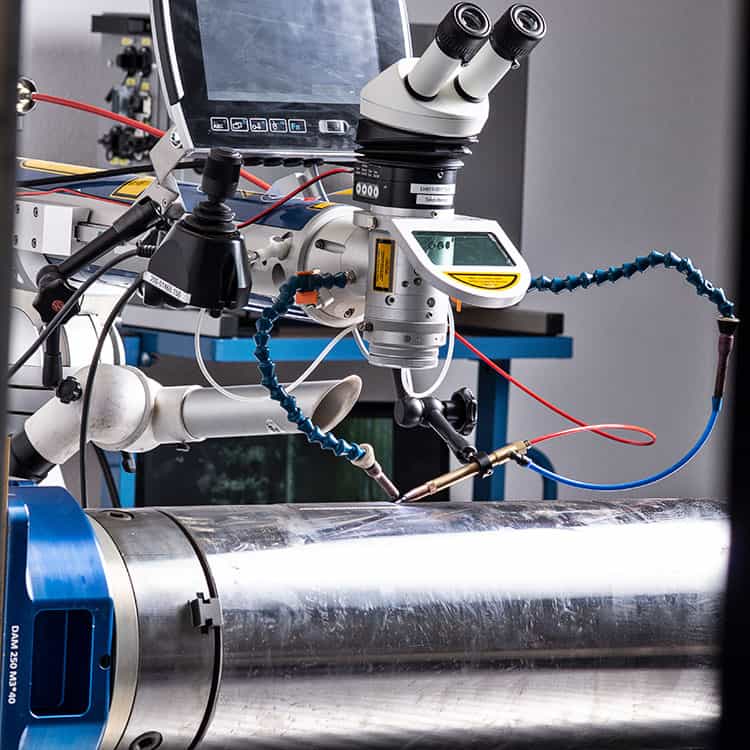

Laser welding leverages a focused beam of high-intensity light to create precise, strong joints in metals. This process is particularly advantageous in the oil and gas industry, where materials like stainless steel, nickel alloys, and titanium are common due to their resistance to corrosion and high temperatures.

The laser’s energy is concentrated in a small area, melting the workpiece without introducing excessive heat to the surrounding material. This control minimises heat-affected zones and preserves the mechanical properties of the component, which is critical for maintaining performance in extreme conditions.

For example, in repairing spindles or shafts, the laser’s precision ensures the weld is applied only where needed, maintaining the integrity of the original structure. The ability to control the depth and width of welds allows for highly specialised repairs, even in areas with restricted access.

Key Benefits of Laser Welding in the Oil & Gas Industry

Durability: Creates strong, long-lasting welds capable of withstanding extreme pressures and temperatures.

Precision: Enables repairs and fabrications with minimal material distortion or loss of mechanical properties.

Cost-Effectiveness: Reduces the need for replacement parts by restoring worn components, lowering overall maintenance costs.

Versatility: Suitable for a wide range of metals and alloys used in oil and gas applications, including stainless steel, nickel alloys, and titanium.

Reduced Downtime: Quick and efficient welding processes minimise operational interruptions.

TLM Laser Solutions for the Oil & Gas Industry

TLM Laser, in partnership with Alpha Laser, provides cutting-edge solutions tailored to the rigorous demands of the oil and gas industry. Our systems deliver unmatched precision and efficiency, whether you’re repairing worn shafts or fabricating intricate components.

Alpha Laser’s mobile and stationary systems offer versatility for both on-site and workshop-based applications. These solutions are designed to address the unique challenges of the sector, including hazardous environments, material-specific requirements, and the need for rapid, reliable repairs.

With TLM Laser, you gain access to expert guidance, state-of-the-art equipment, and a commitment to ensuring your operations run smoothly and safely.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.