Laser Marking & Engraving for the Oil and Gas Industry

Ensure safety, traceability, and compliance in the demanding oil and gas sector with precision laser marking and engraving. Durable, legible, and resistant to harsh conditions, laser-marked components keep your operations reliable.

The Importance of Laser Marking for the Oil and Gas Industry

The oil and gas industry operates under harsh environmental conditions, making durability and traceability essential for safety and operational efficiency. Laser marking is a non-contact, highly precise method for permanent identification on metal and plastic components. Unlike traditional methods, it offers long-lasting results without damaging materials, ensuring that markings withstand extreme temperatures, chemicals, and abrasive conditions.

Laser marking solutions are used to engrave critical information such as serial numbers, part identifiers, and safety certifications on a wide range of components. This not only ensures traceability but also reduces the risk of failure, recalls, and downtime caused by unidentifiable parts.

Laser Marking Applications in Oil & Gas

Laser marking is widely used across various oil and gas applications, meeting the sector’s stringent requirements. These include:

Pipeline Identification: Marking permanent serial numbers, specifications, or inspection records on pipelines to ensure traceability throughout their lifecycle.

Tool and Equipment Marking: Engraving essential details such as ownership information, calibration data, or certifications on tools and machinery to prevent misuse and ensure safety compliance.

Component and Asset Tracking: Marking 2D Data Matrix codes or barcodes on valves, fittings, and other components for inventory management and asset tracking.

Safety and Compliance Markings: Engraving safety warnings, load ratings, or hazard information on critical equipment to meet regulatory standards and enhance workplace safety.

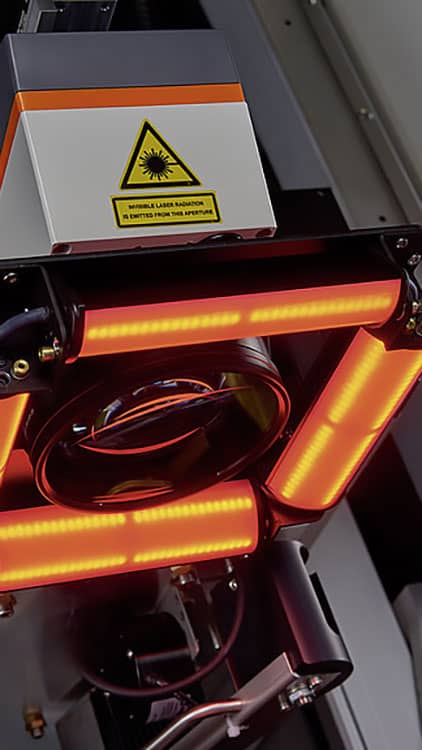

The Science Behind Laser Marking in Oil & Gas

Laser marking works by directing a focused beam of light onto the material surface. Depending on the substrate and application, it can create marks through processes such as engraving, annealing, or ablation. Here’s how these methods apply to the oil and gas sector:

Deep Engraving: Used for components exposed to extreme wear or corrosion, deep engraving ensures marks remain legible even in harsh environments.

Annealing: Common for stainless steel parts, this process produces oxidation marks without removing material, preserving the component’s integrity.

Ablation: Ideal for removing surface coatings to expose the base material, creating high-contrast marks used for barcodes and safety warnings.

Laser marking is favoured for its precision and repeatability, especially in critical applications like pipeline manufacturing and safety equipment certification.

Key Benefits

Laser marking offers a range of advantages that address the unique challenges of the oil and gas industry:

Durability: Marks are resistant to extreme temperatures, corrosion, and harsh chemicals, ensuring longevity in challenging environments.

Traceability: Permanent markings enable seamless tracking of components from production to end-of-life, improving operational efficiency and accountability.

Regulatory Compliance: Meet stringent industry standards with accurate, tamper-proof marks that withstand environmental conditions and inspections.

Eco-Friendly: A non-contact process that eliminates the need for consumables like inks or chemicals, reducing waste and environmental impact.

Versatility: Laser systems can mark various materials, including stainless steel, alloys, and coated surfaces, making them ideal for diverse oil and gas applications.

TLM Laser Solutions for Oil & Gas

At TLM Laser, we partner with FOBA to deliver cutting-edge laser marking systems designed for the oil and gas sector. Our solutions include fully integrated systems for production lines and standalone workstations for precision marking. With features like IMP (Intelligent Mark Positioning) and Mosaic Vision Systems, our lasers guarantee unmatched accuracy, repeatability, and efficiency.

From consultation to implementation, TLM Laser provides tailored solutions to meet your specific needs, ensuring seamless integration into your operations.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.