Laser Cleaning for the Oil & Gas Industry

Laser cleaning has emerged as a game-changing technology for the oil and gas industry, addressing critical challenges such as equipment maintenance, surface preparation, and decontamination. TLM Laser, in partnership with 4JET, provides cutting-edge laser cleaning systems that offer a safer, more efficient, and environmentally friendly solution for oil and gas operations.

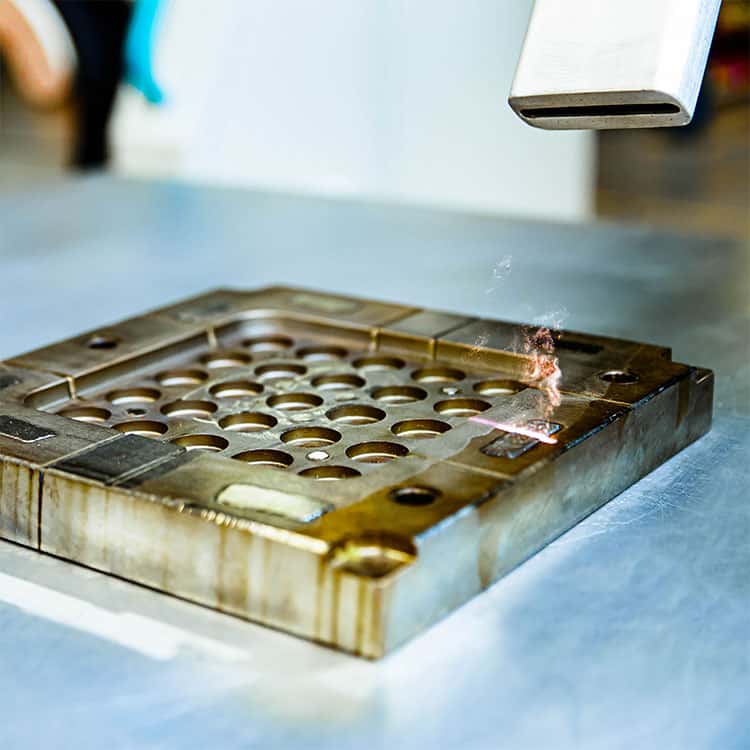

How Laser Cleaning Works

Laser cleaning uses high-intensity laser pulses to vaporise contaminants in a process called ablation. The laser targets impurities without affecting the underlying material, offering a precise, dry, and contactless cleaning solution suitable for the oil and gas sector.

Applications of Laser Cleaning in Oil & Gas

1. Pipeline Maintenance

Laser cleaning effectively removes rust, scale, and coatings from pipelines, ensuring optimal performance and longevity. Its precision reduces the risk of damage to pipeline surfaces, enabling safe and efficient maintenance.

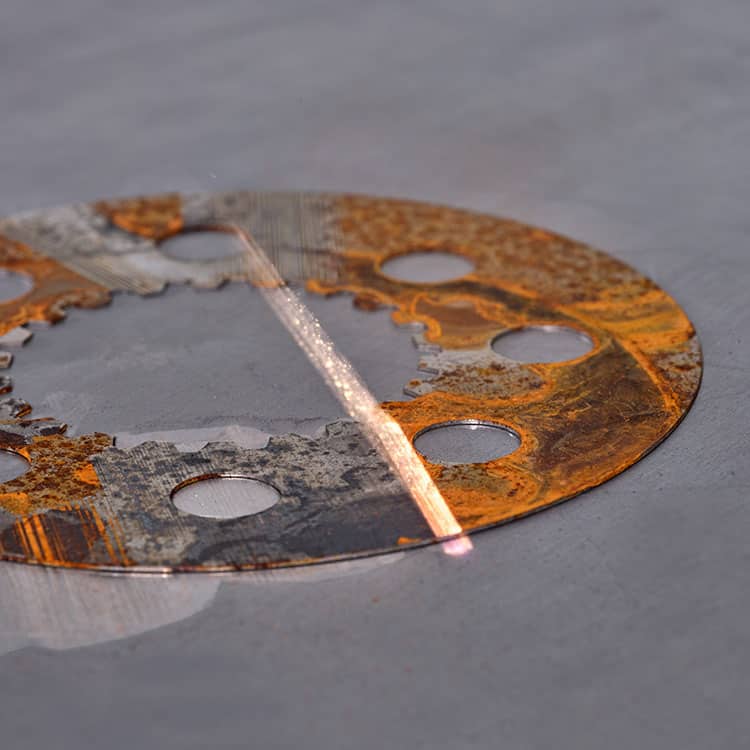

2. Surface Preparation for Welding and Coating

Prepare surfaces for welding or the application of protective coatings by eliminating contaminants such as rust, grease, and old coatings. Laser cleaning ensures a superior bond and extends the lifespan of coatings.

3. Decontamination of Offshore Equipment

Laser systems efficiently clean offshore equipment exposed to harsh environments, including removing marine growth, salt deposits, and other contaminants that compromise equipment integrity.

4. Refinery Equipment Cleaning

Refinery components, such as heat exchangers and storage tanks, can be cleaned of corrosion and residue using lasers, ensuring efficient operations and compliance with safety regulations.

Benefits of Laser Cleaning for the Oil & Gas Industry

1. Improved Safety

Traditional cleaning methods often involve hazardous chemicals and abrasives. Laser cleaning eliminates these risks, creating a safer environment for workers and reducing the potential for chemical exposure or accidental spills.

2. Non-Abrasive and Precise

Laser cleaning preserves the integrity of critical components by removing contaminants without causing wear or damage. This precision is essential for maintaining the reliability of high-stakes oil and gas operations.

3. Environmentally Friendly

By eliminating the need for chemicals or abrasive media, laser cleaning reduces environmental impact and aligns with sustainability goals in the oil and gas industry.

4. Cost-Effective and Efficient

Laser cleaning reduces downtime by enabling faster cleaning and preparation processes. Its efficiency ensures consistent results and lowers long-term maintenance costs.

Compliance with Industry Standards

Laser cleaning systems comply with rigorous health, safety, and environmental standards, including those set by the International Association of Oil & Gas Producers (IOGP). The dry, chemical-free process reduces waste and promotes cleaner operations.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.