Laser Marking & Engraving for the Medical Industry

Laser marking and engraving have become essential processes in the medical industry, offering unmatched precision, traceability, and compliance with stringent regulations. From marking surgical instruments to identifying medical implants, laser technology ensures the highest standards of quality, durability, and reliability required in healthcare.

The Importance of Laser Marking for Medical Device Manufacturing

The medical industry relies on accurate and permanent markings to ensure compliance with regulations such as Unique Device Identification (UDI). UDI mandates that devices are marked with information like batch numbers, serial codes, expiry dates, and other critical data to ensure traceability. Laser marking is the preferred solution for these applications because it creates high-contrast, indelible marks without damaging the underlying material. Unlike other marking methods, laser marking is contamination-free, chemical-free, and resistant to wear, making it ideal for demanding medical environments.

Laser Marking Applications in Medical Device and Pharmaceutical Manufacturing

Medical Devices and Instruments: Surgical tools, diagnostic equipment, and other devices require precise markings for identification, batch tracking, and compliance.

Medical Implants: From orthopaedic implants to dental prosthetics, laser marking provides biocompatible, durable marks that withstand sterilisation and usage over time.

Pharmaceutical Packaging: Laser marking is used for blister packs, syringes, and medicine jars, ensuring clear and legible information for patient safety and regulatory compliance.

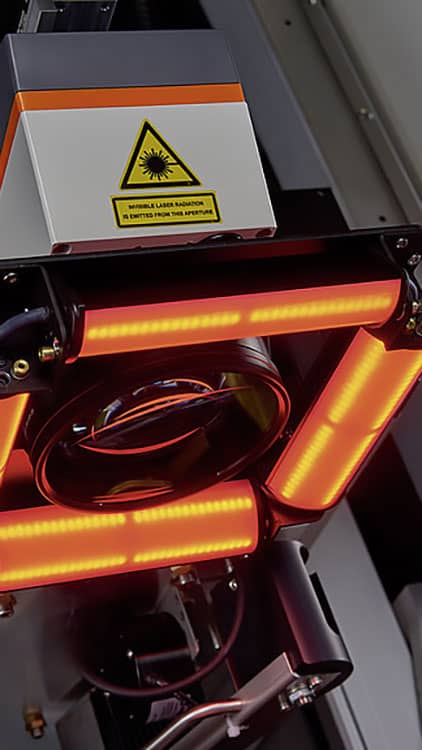

The Science Behind Laser Marking in the Medical Sector

Laser marking uses focused beams of light to create precise, permanent marks by altering the surface of the material. The process is non-contact, making it ideal for delicate medical devices. Here are some common techniques used:

- Annealing: Alters the surface colour of metals, such as stainless steel, without engraving into the material, ensuring a smooth, non-porous surface ideal for medical applications.

- Foaming: Produces raised marks with high contrast on plastics.

- Ablation: Removes coatings or layers, such as paint, to expose the underlying material for marking.

Key Benefits of Laser Marking in Healthcare

Traceability for Compliance and Safety

Laser marking provides precise, permanent markings essential for ensuring traceability in compliance with regulations like UDI (Unique Device Identification). These marks allow healthcare providers to track the origin, manufacturing details, and lifecycle of medical devices and implants, reducing the risk of counterfeiting and enhancing patient safety.

Durable and Sterilisation-Resistant Markings

The durability of laser markings makes them ideal for medical devices that undergo frequent sterilisation processes, including autoclaving, chemical cleaning, and high-temperature exposure. These marks remain legible and intact even under the harshest conditions, ensuring long-term reliability.

Eco-Friendly and Cost-Efficient

Unlike traditional marking methods, laser marking eliminates the need for consumables like inks, chemicals, or etching agents. This not only reduces operational costs but also supports sustainability by minimising waste and avoiding harmful by-products.

Compliance with Global Standards

Laser marking adheres to stringent global medical standards, including FDA UDI requirements and ISO 13485 quality management systems. These marks help manufacturers ensure regulatory compliance across international markets.

Future-Ready Technology

Laser marking systems can be seamlessly integrated into automated production lines, offering scalability for growing demands. The technology also supports Industry 4.0 initiatives by allowing data integration and remote monitoring for advanced process control.

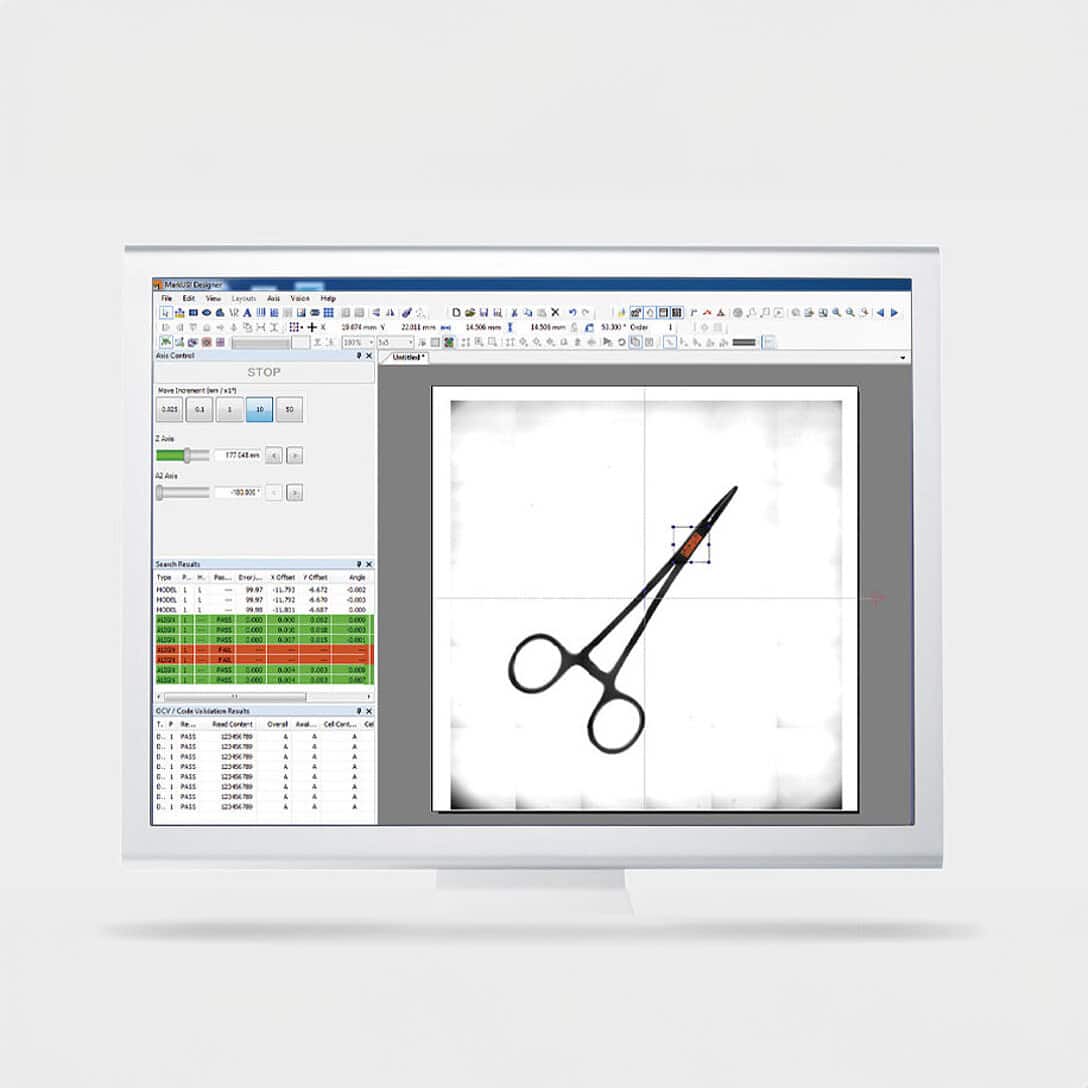

Innovative Vision Systems Designed Perfectly for Medical Marking

Partnered with FOBA, TLM Laser delivers advanced marking solutions equipped with state-of-the-art vision systems. These systems ensure unparalleled precision, reduce waste, and enhance productivity:

- Intelligent Mark Positioning (IMP): Ensures accurate mark placement with pre-mark and post-mark validation, reducing defective products by up to 90%.

- Point & Shoot™: Simplifies manual positioning with a camera-guided system, improving efficiency and consistency.

These technologies are integral for maintaining the high standards of precision and reliability required in medical manufacturing.

TLM Laser provides cutting-edge FOBA laser marking systems tailored to the needs of the medical sector. With over a decade of experience, we offer turnkey solutions, from standalone systems to fully integrated production lines. Our expertise extends to supporting equipment, including BOFA fume extraction systems and Univet safety eyewear, ensuring a complete, compliant, and safe setup for your operations.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.