Laser Welding for the Marine Industry

Enhance durability and efficiency with laser welding solutions tailored for the marine industry. Deliver precision repairs and fabrications that stand strong against the challenges of harsh marine environments.

The Importance of Laser Welding for the Marine Industry

The marine industry faces relentless challenges from saltwater corrosion, high humidity, and constant mechanical stress. These conditions demand durable and precise welding solutions for shipbuilding, repairs, and component maintenance. Laser welding addresses these needs by offering superior accuracy, reduced heat-affected zones, and reliable results across a variety of materials.

Unlike traditional welding methods, laser welding minimises distortion and ensures strong, long-lasting joints. Its versatility and precision make it an invaluable tool for maintaining and fabricating marine components, enabling cost-effective repairs and extended equipment lifespans.

Key Applications of Laser Welding in the Marine Industry

Laser welding is revolutionising the marine industry with its ability to perform high-precision welds in demanding applications, including:

Engine Components: Repair or assemble parts such as cylinder heads, valves, and manifolds, ensuring reliable engine operation in harsh conditions.

Hull Repairs and Reinforcements: Seamlessly weld or repair sections of ship hulls, ensuring structural integrity and water-tightness.

Propulsion Systems: Join components such as propeller blades and drive shafts with high strength and precision to optimise vessel performance.

Pipeline and Tank Welding: Achieve robust, corrosion-resistant welds for fuel, water, and chemical storage systems aboard ships.

Deck Equipment and Fixtures: Fabricate and repair winches, cranes, and other essential deck machinery to withstand heavy loads and marine exposure.

The Science Behind Laser Welding in the Marine Industry

Laser welding for the marine sector relies on the controlled application of high-intensity laser beams to join metal components with precision. This process significantly reduces the heat-affected zone (HAZ), minimising the risk of warping or weakening surrounding materials—an essential feature for large-scale marine structures like ship hulls and tanks.

The marine industry frequently uses metals like stainless steel, aluminium alloys, and high-strength steels due to their corrosion resistance and durability. Laser welding effectively joins these materials, even when they have varying thermal properties. Its precision ensures that welds are strong, consistent, and resistant to the stresses of marine operations.

Additionally, laser welding supports automation and remote operation, making it ideal for challenging marine environments. Automated systems can perform consistent welds with minimal human intervention, reducing safety risks during repair and fabrication processes in shipyards or at sea.

Key Benefits of Laser Welding for the Marine Industry

Corrosion Resistance: Achieve robust welds that withstand saltwater exposure and harsh marine conditions.

High Precision: Perform detailed repairs and fabrications with minimal material distortion.

Durability: Create strong, reliable joints capable of withstanding mechanical stresses and vibrations.

Material Compatibility: Weld a wide range of marine-grade metals, including aluminium, stainless steel, and copper alloys.

Cost Efficiency: Reduce downtime and material waste with faster, more accurate welding processes.

TLM Laser Solutions for the Marine Industry

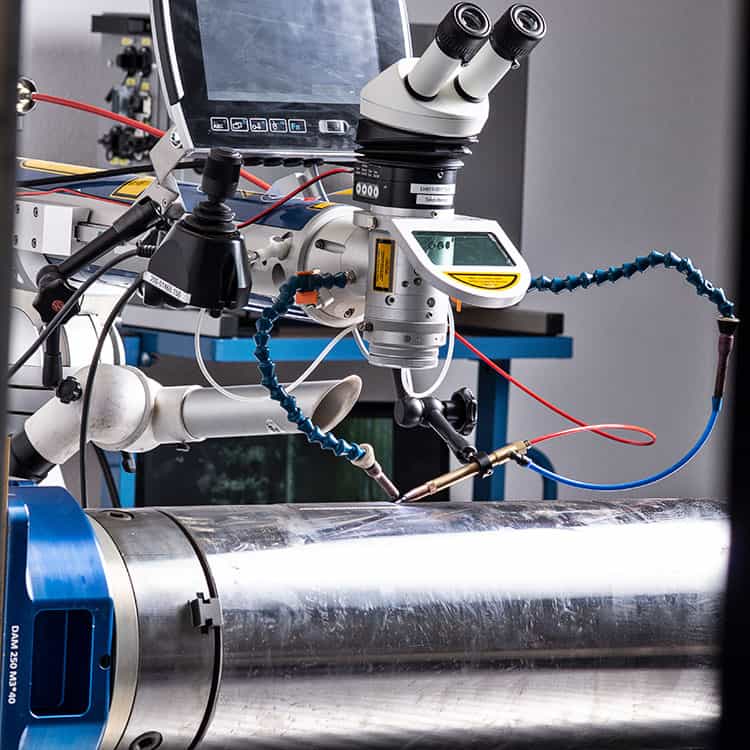

TLM Laser, in partnership with Alpha Laser, delivers advanced laser welding systems designed to meet the demanding needs of the marine industry. Our mobile and stationary laser systems provide unmatched flexibility, allowing for both on-site repairs and in-facility fabrications.

Whether you’re addressing hull damage, fabricating propulsion systems, or maintaining deck equipment, Alpha Laser’s solutions offer precision, durability, and reliability. With their ease of use and ability to weld challenging materials, these systems ensure efficient operations and reduced maintenance costs.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.