Laser Marking & Engraving for the Marine Industry

Enhance durability, traceability, and compliance in the marine industry with precision laser marking and engraving solutions tailored for maritime environments.

The Importance of Laser Marking for the Marine Industry

The marine industry operates under unique conditions where components and materials are exposed to saltwater, high humidity, and corrosive environments. These challenges demand robust identification and marking methods that remain legible and durable over time. Laser marking stands out as the ideal solution, offering permanent, high-contrast markings that withstand the harshest marine conditions.

From marking ship components to labelling safety equipment, laser systems ensure traceability, safety, and compliance with maritime regulations. The non-contact nature of laser marking preserves the integrity of materials, making it suitable for a wide range of marine applications.

Laser Marking Applications in the Marine Industry

Laser marking and engraving systems are employed across various marine applications, including:

Component Traceability: Permanently marking serial numbers, batch codes, and barcodes on ship components and spare parts to ensure accurate tracking and maintenance.

Safety Equipment Labelling: Marking life-saving equipment such as life vests, buoys, and fire extinguishers with clear identification and compliance details to meet maritime safety standards.

Corrosion-Resistant Markings: Engraving durable marks on metal parts like propellers, anchors, and hull components to maintain visibility even in corrosive saltwater environments.

Customised Branding: Adding logos, vessel names, and decorative designs to enhance the aesthetic appeal and identification of marine equipment and vessels.

Maintenance Tools Identification: Marking tools and repair equipment with unique identifiers to prevent loss and ensure efficient operations on board.

The Science Behind Laser Marking in the Marine Industry

Laser marking leverages precision laser beams to create permanent marks on surfaces through various processes. Each method offers distinct advantages for marine applications:

Annealing: Creates oxidation marks without damaging the material’s surface, ideal for stainless steel components used in marine environments.

Deep Engraving: Penetrates material surfaces to produce long-lasting marks that remain legible even under abrasive conditions like saltwater exposure.

Ablation: Removes coatings to expose the base material, creating high-contrast marks suitable for safety labelling and decorative designs.

Surface Etching: Produces shallow, detailed marks for aesthetic and functional purposes, ensuring clarity and precision.

These processes ensure that laser markings maintain their integrity, readability, and adherence to maritime safety and compliance standards.

Key Benefits

Laser marking offers a host of benefits tailored to the demands of the marine industry:

Durability: Resistant to corrosion, UV exposure, and extreme temperatures, ensuring markings remain legible over the equipment’s lifespan.

Traceability: Unique identifiers like serial numbers and QR codes enable efficient tracking and maintenance of ship components.

Regulatory Compliance: Meet strict maritime safety standards with clear, tamper-proof markings on essential equipment and components.

Eco-Friendly: A chemical-free, non-contact process that reduces waste and supports environmentally conscious marine operations.

Versatility: Capable of marking various materials, including metals, plastics, and composites, making it ideal for diverse marine applications.

TLM Laser Solutions for the Marine Industry

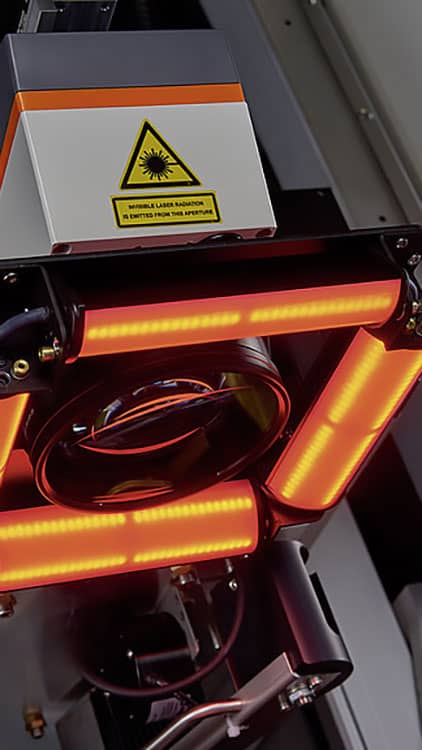

At TLM Laser, we provide advanced laser marking systems in partnership with FOBA, tailored to meet the unique challenges of the marine industry. Our solutions offer precision, durability, and flexibility, ensuring seamless integration into your maritime operations.

With features like IMP (Intelligent Mark Positioning) for accurate part alignment and FOBA Mosaic for fixtureless marking, our systems deliver consistent, reliable results in high-demand environments. Whether you require standalone systems or integrated solutions, TLM Laser can help you achieve optimal performance.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.