Laser Cleaning for the Marine Industry

Laser cleaning is revolutionising maintenance practices in the marine industry, offering a safer, more sustainable, and highly efficient way to remove contaminants from vessels, equipment, and structures. TLM Laser, in partnership with 4JET, provides state-of-the-art laser cleaning solutions that address the unique challenges of marine environments, including corrosion, biofouling, and surface preparation.

How Laser Cleaning Works

Laser cleaning uses high-energy light pulses to vaporise contaminants, including rust, paint, and marine growth, in a process known as ablation. The laser selectively targets impurities while leaving the underlying material unaffected, making it an ideal choice for delicate or intricate surfaces.

Applications of Laser Cleaning in the Marine Industry

1. Hull Cleaning and Maintenance

Laser cleaning effectively removes rust, marine growth, and old paint from ship hulls, improving fuel efficiency and extending the vessel’s operational lifespan. Its precision ensures the substrate remains intact, unlike abrasive cleaning methods.

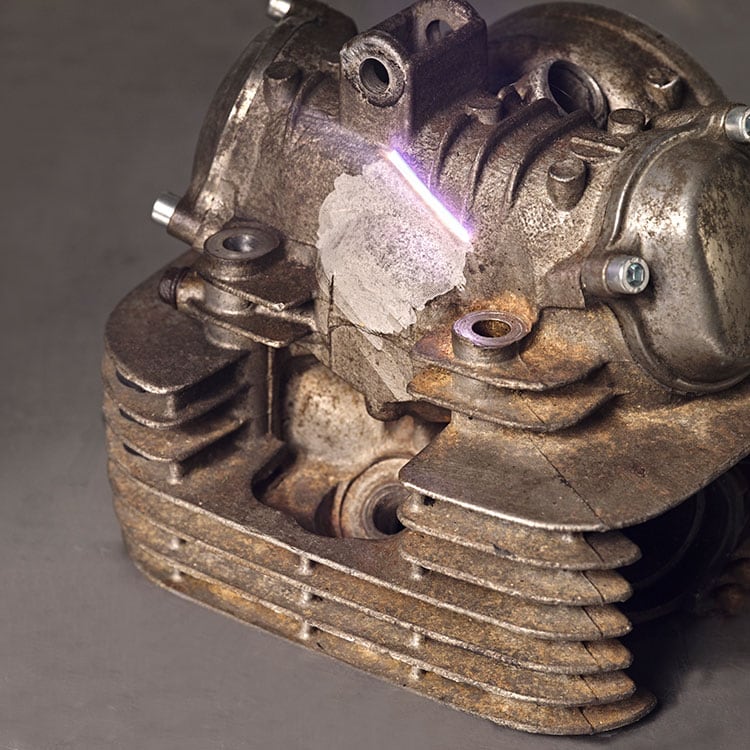

2. Propeller and Engine Component Cleaning

Marine engines and propellers accumulate rust, grease, and carbon deposits over time. Laser cleaning restores these components to optimal condition without causing wear, enhancing performance and reliability.

3. Surface Preparation for Painting and Coating

Before repainting or applying protective coatings, laser cleaning ensures a contaminant-free surface, improving adhesion and durability. This is particularly valuable in preventing corrosion in harsh marine environments.

4. Restoration of Historical Marine Artefacts

Laser cleaning’s precision and non-abrasive nature make it ideal for restoring historical ships, anchors, and other marine artefacts, preserving their integrity while removing dirt, rust, or paint.

Benefits of Laser Cleaning for the Marine Industry

1. Environmentally Friendly

Laser cleaning eliminates the need for chemicals or abrasive materials, reducing waste and preventing contamination of marine ecosystems.

2. Cost and Time Efficiency

Laser cleaning accelerates maintenance processes, minimising downtime for vessels and structures. Its efficiency reduces labour costs and ensures faster project completion.

3. Non-Abrasive and Precise

Unlike traditional cleaning methods, laser cleaning preserves the integrity of surfaces, making it suitable for sensitive components and intricate designs.

4. Enhanced Safety

With no hazardous chemicals or abrasive particles involved, laser cleaning promotes a safer working environment for marine maintenance teams.

Compliance with Marine Standards

Laser cleaning aligns with marine industry standards for environmental and operational safety, including those set by the International Maritime Organisation (IMO). Its dry and sustainable approach ensures compliance with stringent regulations.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.