Laser Processing for the Marine Industry

Marine manufacturing demands durable and corrosion-resistant components built for performance in harsh environments. TLM Laser provides advanced laser systems for marking, welding, cutting, and cleaning, helping manufacturers deliver high-quality marine solutions.

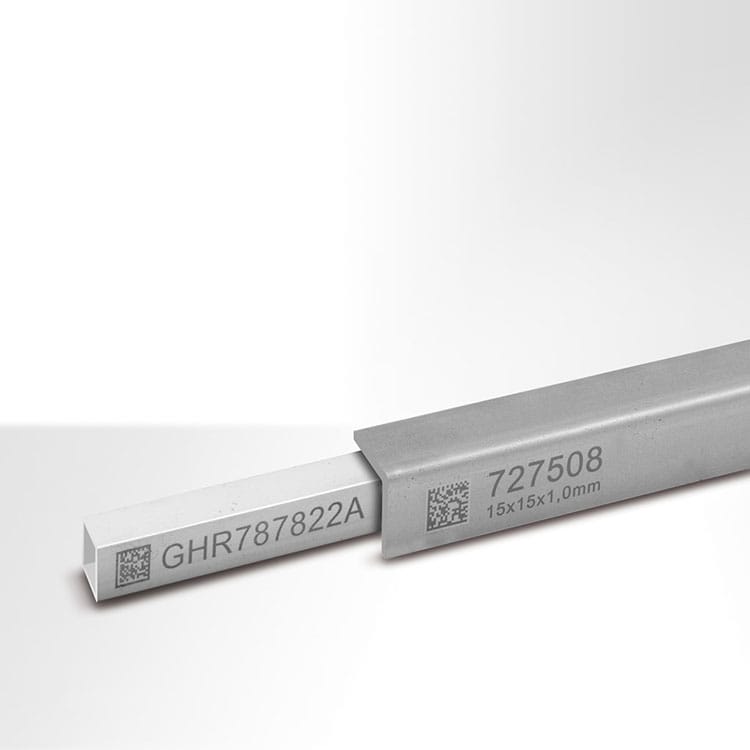

Marking Systems for Durable Marine Components

TLM Laser supplies marking systems that deliver durable, high-contrast marks on marine components such as propellers, hull fittings, and control systems. These marks ensure compliance with safety and identification standards while withstanding the harsh conditions of marine environments.

Corrosion-Resistant Welds for Shipbuilding Applications

Our laser welding systems support the assembly and repair of marine equipment, including ship hull components and structural frameworks. These machines provide strong, corrosion-resistant welds that ensure long-term durability and reliability in challenging marine conditions.

Cleaning Solutions for Long-Term Marine Equipment Maintenance

TLM Laser offers laser cleaning systems designed to remove rust, coatings, and marine fouling from metal surfaces and equipment. This non-abrasive method is ideal for maintaining and restoring marine components, improving performance, and reducing downtime.

Precision Cutting for Structural and Custom Marine Parts

Our laser cutting systems enable manufacturers to produce high-precision parts for marine applications, including structural components, engine casings, and custom fittings. These machines ensure efficient production, reduced waste, and high-quality results suitable for marine environments.

Innovate with Confidence

Laser Machines and Systems

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.