Laser Welding for Industrial Machinery

Optimise your industrial machinery production and maintenance with advanced laser welding solutions. Precision, durability, and efficiency combine to meet the demands of modern manufacturing and repair.

The Importance of Laser Welding for Industrial Machinery

The industrial machinery sector relies on robust, reliable, and durable components to keep production lines running efficiently. Laser welding offers a cutting-edge solution for joining, repairing, and maintaining critical machine parts with unmatched precision and strength.

Traditional welding techniques often fall short when working with complex designs, delicate materials, or high-precision requirements. Laser welding fills these gaps, offering a non-contact process that reduces material stress, ensures consistency, and enhances durability.

Key Applications of Laser Welding in Industrial Machinery

Laser welding is indispensable for various applications in industrial machinery production and maintenance, including:

Machinery Maintenance and Refurbishment: Perform targeted repairs on equipment, reducing downtime and extending machine life.

Precision Component Manufacturing: Create durable, high-strength welds for gears, bearings, and other critical machine parts.

Tool and Die Repair: Restore worn or damaged tools and dies with pinpoint accuracy, extending their operational lifespan.

Custom Fabrication: Seamlessly join intricate components for bespoke machinery designs.

Seam Welding: Ensure air-tight and water-tight seals for components like hydraulic cylinders and pressure vessels.

The Science Behind Laser Welding in Industrial Machinery

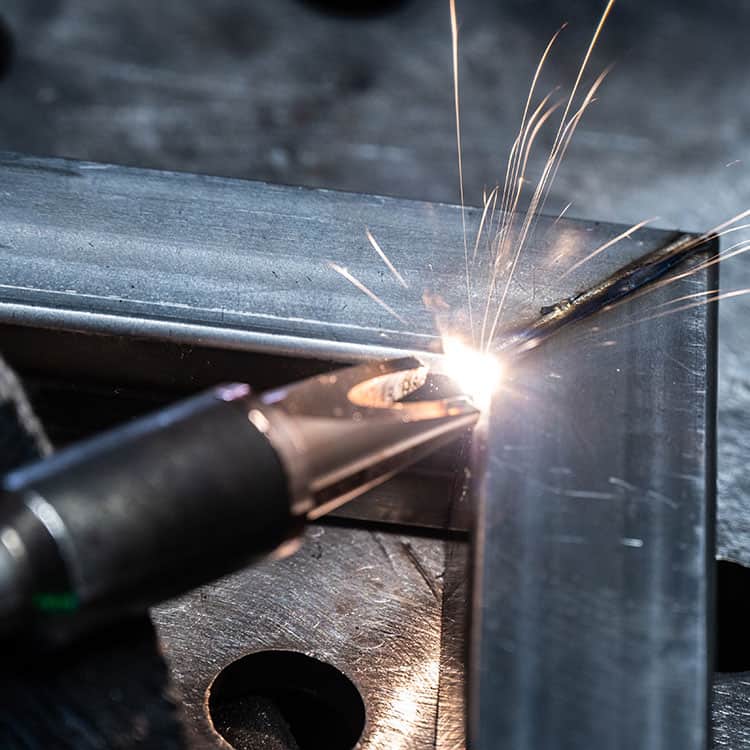

Laser welding utilises a focused beam of light to join materials at the molecular level, delivering exceptional precision and control. This process minimises heat transfer to surrounding areas, preserving the integrity of the base material and reducing the risk of warping or distortion.

For industrial machinery, laser welding is particularly beneficial due to its ability to handle complex geometries and dissimilar materials. The high-intensity laser beam enables deep weld penetration, ensuring strong and durable joins for heavy-duty applications.

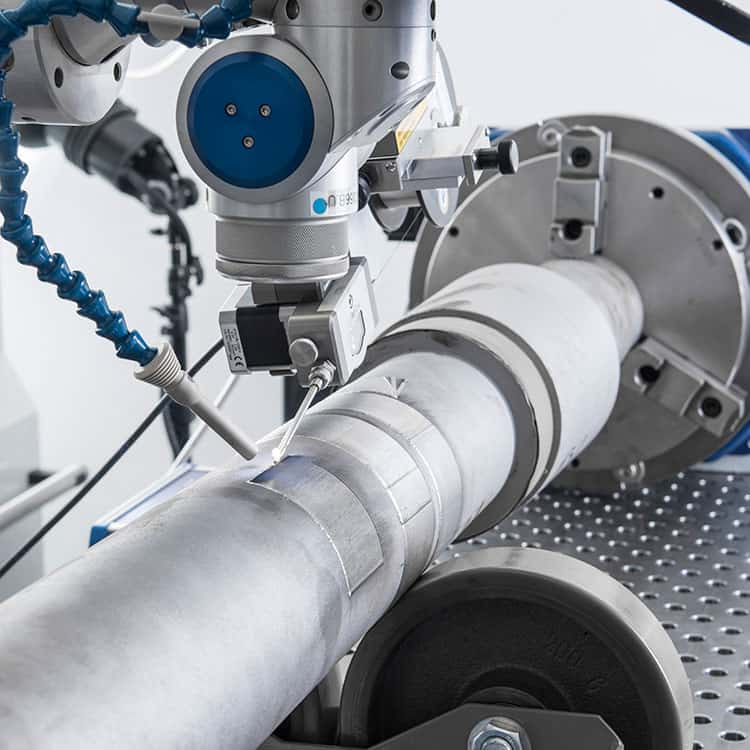

Automation further enhances the efficiency of laser welding in industrial settings. Robotic laser welding systems ensure consistent quality and high-speed production, even in challenging environments. This makes it an ideal choice for manufacturers seeking to scale operations while maintaining exacting standards.

Key Benefits of Laser Welding for Industrial Machinery

Durability and Strength: Achieve welds capable of withstanding heavy loads and continuous use in demanding industrial environments.

Precision: Handle intricate designs and small components with unmatched accuracy.

Versatility: Seamlessly weld dissimilar materials and complex geometries, accommodating a wide range of applications.

Reduced Downtime: Perform quick, targeted repairs to minimise operational disruptions.

Cost Efficiency: Lower consumable usage and reduced post-weld finishing requirements cut costs significantly.

TLM Laser Solutions for Industrial Machinery

At TLM Laser, we provide cutting-edge laser welding systems tailored to the unique demands of industrial machinery production and maintenance. Partnering with Alpha Laser, we offer advanced solutions that prioritise precision, reliability, and efficiency.

From fabricating new components to refurbishing worn equipment, our laser welding systems help manufacturers and maintenance teams achieve superior results with reduced effort. Our expertise ensures seamless integration into your operations, helping you stay competitive in a fast-paced industry.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.