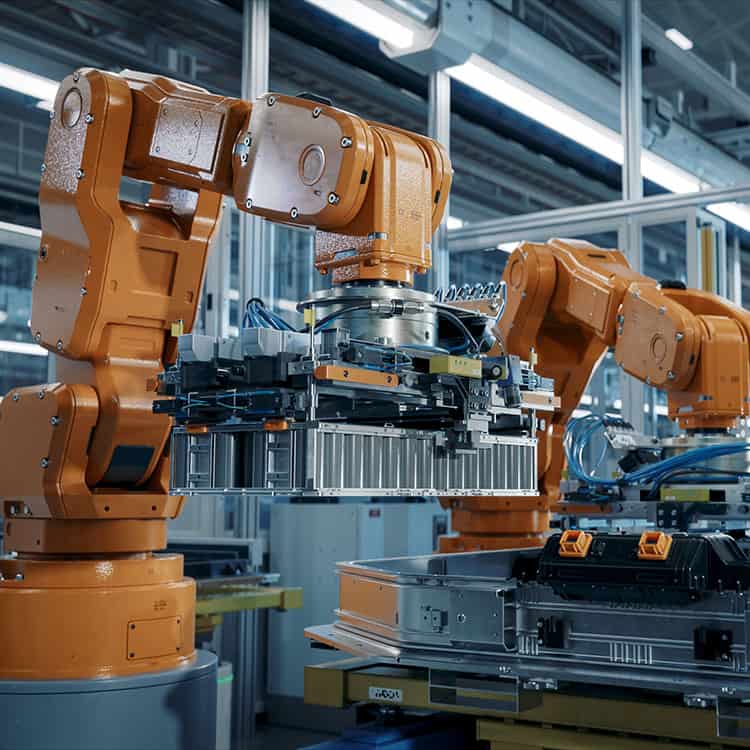

Laser Marking & Engraving for Industrial Machinery

Industrial machinery often operates under demanding conditions, requiring durable and precise markings for identification, traceability, and compliance. Laser marking and engraving are ideal solutions, offering long-lasting, tamper-proof markings on components and assemblies. From branding to serialisation, this technology ensures that machinery and tools meet stringent industry standards while supporting operational efficiency.

Applications of Laser Marking in Industrial Machinery

Laser marking is versatile, serving various applications within the industrial machinery sector. Key uses include:

Part Identification and Serialisation:

Components such as gears, bearings, and housings are laser-marked with serial numbers, barcodes, and QR codes for seamless traceability.

Branding and Logos:

Permanent branding, including company logos, enhances the professional presentation of machinery.

Maintenance Marking:

Instructions, safety warnings, or maintenance guides can be etched directly onto equipment, ensuring durability in harsh environments.

Tool and Die Marking:

Laser engraving ensures precise identification of tools and dies, reducing errors in manufacturing and repair processes.

The Science Behind Laser Marking for Industrial Machinery

Laser marking employs a focused beam of light to create precise marks on various materials. The process is highly adaptable depending on the component and application:

- Annealing: Creates smooth, high-contrast marks on metals such as steel, ideal for long-term readability without surface disruption.

- Engraving: Removes material to create deep, permanent marks, suitable for heavy-duty tools and components.

- Ablation: Removes surface coatings, exposing the underlying material for contrast markings.

- Etching: Produces shallow, detailed marks for logos, branding, or part numbers.

These techniques ensure that every mark meets the durability and clarity standards required in industrial applications.

Key Benefits of Laser Marking in Industrial Machinery

Durability:

Laser-marked identifiers withstand extreme temperatures, abrasion, and chemical exposure, ensuring longevity.

Precision:

High-resolution laser systems create intricate designs and fine details, even on small components.

Efficiency:

Laser marking systems operate quickly and can be automated for seamless integration into production lines.

Material Versatility:

Compatible with a wide range of materials, including metals, plastics, ceramics, and composites.

Eco-Friendly:

Unlike ink-based methods, laser marking is a consumable-free process that generates minimal waste.

Applications of Laser Engraving for Industrial Machinery

Engraving provides deeper, more durable markings for industrial use cases. Applications include:

Heavy-Duty Equipment Marking: Ensures that essential safety and operational information remains legible under harsh conditions.

Tool Engraving: Permanent marks on tools improve inventory management and reduce loss.

Mould Engraving: Creates detailed moulds for high-precision manufacturing processes.

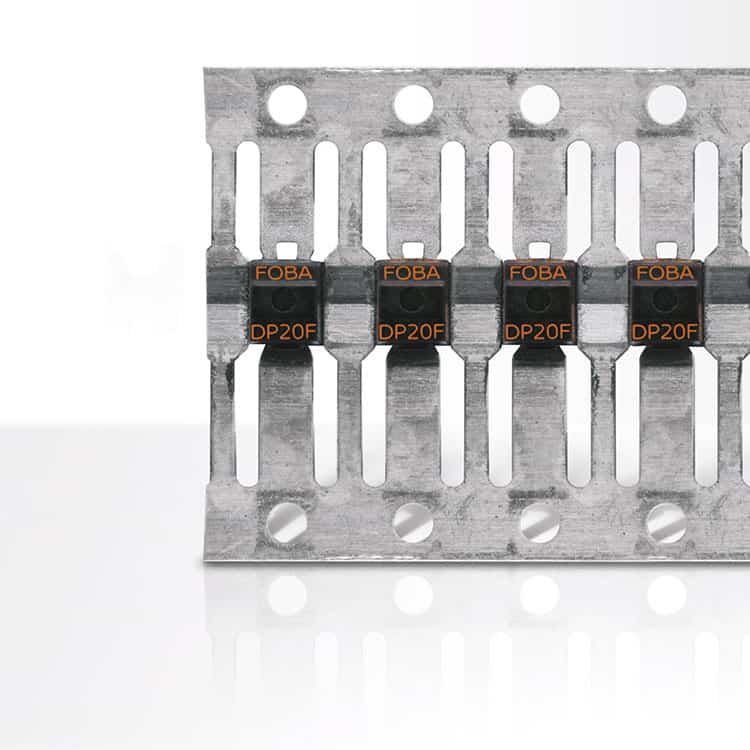

FOBA Laser Marking Solutions for Industrial Machinery

FOBA offers advanced laser marking systems designed specifically for the needs of industrial machinery manufacturers. Features include:

- IMP (Intelligent Mark Positioning): Ensures precise alignment of markings, reducing errors and improving efficiency.

- MOSAIC Vision System: Allows fixtureless marking for complex components, streamlining production.

- Closed-Loop Verification: Incorporates pre- and post-marking validation for superior quality control.

At TLM Laser, we specialise in providing tailored laser marking solutions for industrial machinery manufacturers. Partnering with leading brands like FOBA, we deliver state-of-the-art systems backed by expert support. Whether you’re looking to enhance traceability, branding, or operational efficiency, our solutions are designed to meet your unique needs.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.