Laser Cleaning for Industrial Machinery

Laser cleaning technology offers unparalleled precision, efficiency, and environmental benefits for maintaining and preparing industrial machinery. By using high-energy laser pulses, contaminants such as rust, grease, coatings, and oxides can be effectively removed without damaging the underlying material.

How Laser Cleaning Works

Laser cleaning uses the principle of laser ablation, where focused laser energy vaporises surface contaminants. The laser is tuned to target specific materials such as rust or coatings, leaving the base material untouched. This non-contact and eco-friendly process is ideal for a range of industrial applications.

Key Features:

- Non-Abrasive Process: Protects sensitive machinery surfaces.

- Dry and Chemical-Free: Eliminates the need for solvents or abrasive materials.

- Automation Ready: Easily integrates into production lines or can be used manually for precision cleaning.

Applications of Laser Cleaning in Industrial Machinery

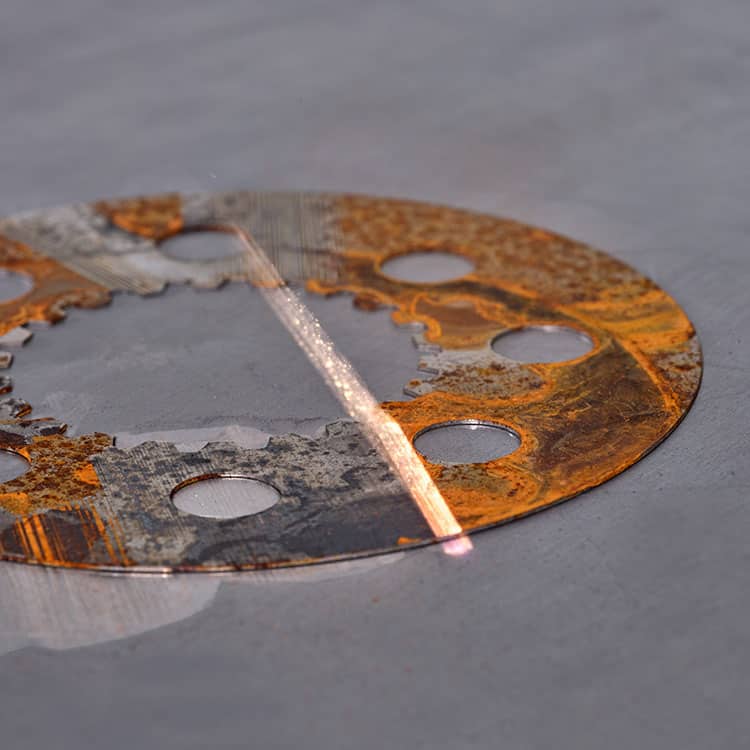

1. Rust and Oxide Removal

Laser cleaning effectively eliminates rust and oxides from machinery components, preparing them for further processing or restoring them to optimal condition. for example, laser technology has been used to restore conveyor systems in manufacturing facilities, efficiently removing contaminants like grease without harming the equipment.

2. Surface Preparation for Coatings

Prepare machinery surfaces for painting, bonding, or coating by removing contaminants such as grease, oil, and old coatings. This ensures better adhesion and a higher-quality finish, essential for maintaining equipment performance and appearance.

3. Maintenance of Tools and Dies

Clean industrial tools and dies efficiently without abrasive damage, ensuring consistent product quality and extending tool life. Laser cleaning preserves the precision and integrity of these critical components, making it ideal for industries with high manufacturing standards.

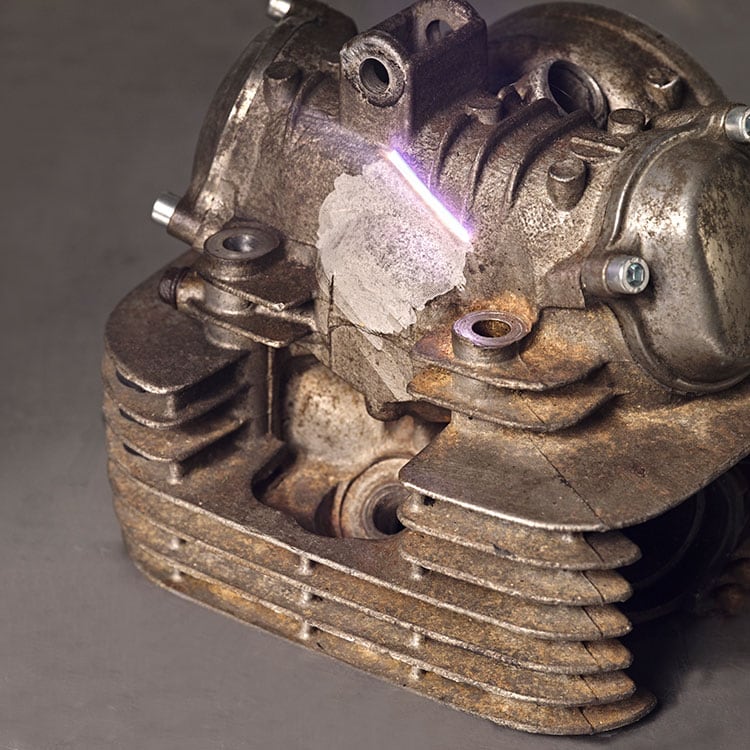

4. Cleaning of Complex Geometries

Laser cleaning can access intricate parts and hard-to-reach areas of machinery, offering unparalleled versatility for industrial maintenance. Its precision allows for effective cleaning of components with complex shapes without the need for disassembly.

Benefits of Laser Cleaning for Industrial Machinery

1. Prolonged Machinery Lifespan

By removing contaminants without mechanical or chemical stress, laser cleaning ensures the durability and efficiency of high-value machinery. Regular laser cleaning can prevent corrosion and wear, extending equipment service life.

2. Minimise Downtime

Laser cleaning’s speed and precision reduce the time needed for maintenance, keeping your production line running smoothly. Its efficiency allows for quick turnaround times during scheduled maintenance.

3. Cost-Effective Maintenance

While the initial investment may be higher, eliminating the need for consumables such as solvents or abrasives leads to long-term cost savings. Additionally, reduced downtime and extended equipment lifespan contribute to overall operational cost efficiency.

4. Eco-Friendly Operations

Laser cleaning is a sustainable solution that generates minimal waste, aligning with modern environmental standards in industrial settings. It eliminates the use of hazardous chemicals, reducing environmental impact and improving workplace safety.

Why Choose Laser Cleaning for Industrial Machinery?

Precision and Consistency

Laser cleaning delivers repeatable results, making it ideal for industries requiring high-quality maintenance and surface preparation.

Compliance with Industry Standards

Adhering to industry standards is crucial for ensuring safety and quality in laser cleaning processes. The International Organisation for Standardisation (ISO) is developing standards such as ISO/WD 8504-6, which specifies laser cleaning methods for the preparation of steel surfaces before coating with paints and related products. Additionally, ISO 11553-1 outlines safety requirements for laser processing machines, ensuring operator safety during laser cleaning operations.

Versatile Applications

From heavy-duty machinery to delicate precision tools, laser cleaning is adaptable to a wide range of industrial needs.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.