Laser Marking & Engraving for the Energy Industry

Empowering the energy sector with precision laser marking and engraving for durable, traceable, and compliant components.

The Importance of Laser Marking for the Energy Industry

The energy industry operates in extreme environments, where reliability, durability, and compliance are paramount. From renewable energy components to oil and gas infrastructure, every part must be identifiable and traceable throughout its lifecycle. Laser marking and engraving provide a permanent, high-contrast solution that meets these critical demands.

Unlike traditional marking methods, laser technology offers unmatched precision, durability, and eco-friendliness. It enables non-contact marking on diverse materials, ensuring legibility under the harshest conditions, such as extreme temperatures, corrosion, and high pressure.

Laser Marking Applications in the Energy Industry

Laser marking and engraving have broad applications across the energy sector, supporting safety, efficiency, and regulatory compliance:

Traceability of Components

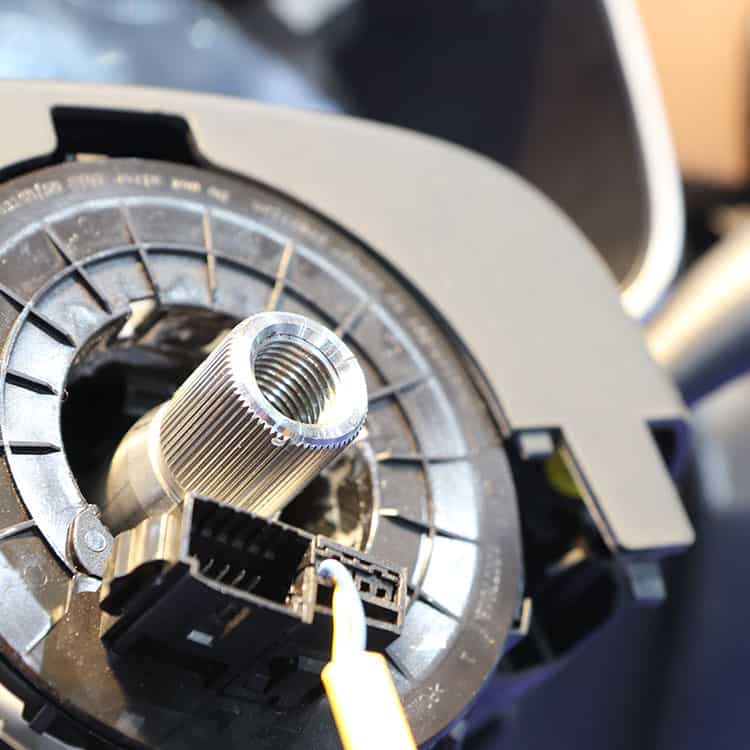

Marking serial numbers, QR codes, and 2D Data Matrix codes on equipment such as turbines, pipelines, and control panels ensures seamless tracking throughout manufacturing, deployment, and maintenance.

Regulatory Compliance

Clear and permanent markings help manufacturers meet international safety standards and regulations, such as CE markings and product certifications.

Safety Instructions and Warnings

Laser-engraved safety labels and operational instructions on hazardous energy equipment reduce risks and ensure proper handling by personnel.

Part Identification and Maintenance

Laser markings provide critical information, such as specifications and part numbers, to simplify maintenance and repairs in energy facilities.

Customisation for Branding

High-precision laser engraving allows manufacturers to add logos or unique identifiers to components, enhancing brand visibility and authenticity.

The Science Behind Laser Marking in the Energy Industry

Laser marking works by focusing a high-energy beam of light onto a material’s surface, creating a permanent mark. Different marking processes are tailored to suit the energy industry’s diverse material requirements:

Annealing

Ideal for marking metals like stainless steel, this method creates smooth, corrosion-resistant markings through oxidation, preserving the material’s surface.

Deep Engraving

Used for components exposed to high wear and tear, deep engraving ensures that markings remain legible despite mechanical abrasion or environmental conditions.

Ablation

This technique removes coatings, such as paint or anodisation, to reveal the base material underneath, enabling high-contrast marks.

Black Marking

Black marking uses ultra-short laser pulses to create dark, high-contrast marks that remain legible in extreme environments, such as high heat or chemical exposure.

Key Benefits

Laser marking offers transformative advantages for the energy industry, ensuring operational efficiency and component longevity:

Durability

Laser markings withstand harsh conditions, including UV exposure, high temperatures, and corrosive environments, ensuring long-term readability.

Precision

High-resolution lasers create intricate and detailed markings, even on small or irregularly shaped components.

Sustainability

Laser marking is an eco-friendly process, eliminating the need for consumables like inks or chemicals and reducing waste.

Non-Contact Marking

The non-invasive process protects the structural integrity of sensitive components, ensuring they remain fully functional.

Traceability and Compliance

Permanent, tamper-proof markings provide complete traceability and help meet stringent industry regulations.

TLM Laser Solutions for the Energy Industry

TLM Laser offers cutting-edge laser marking and engraving systems designed for the energy sector’s unique needs. Our systems, in partnership with FOBA, provide the precision, speed, and durability required for energy components. Whether marking turbine parts, oil and gas pipelines, or renewable energy equipment, TLM’s solutions ensure exceptional performance and reliability.

Our advanced features, such as Intelligent Mark Positioning (IMP) and FOBA Mosaic, provide error-free and repeatable marking, optimising productivity and ensuring compliance. With expertise in integrating laser systems into existing production lines, TLM Laser is the trusted partner for energy manufacturers looking to enhance their operations.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.