Laser Cutting for Electrical and Electronic Component Manufacturing

In the fast-paced world of electrical and electronic component manufacturing, precision is critical. Laser cutting technology provides unmatched accuracy, flexibility, and efficiency, ensuring that every component meets stringent quality standards. From circuit boards to microelectronic housings, laser cutting is the go-to solution for manufacturers striving to achieve optimal performance and reliability.

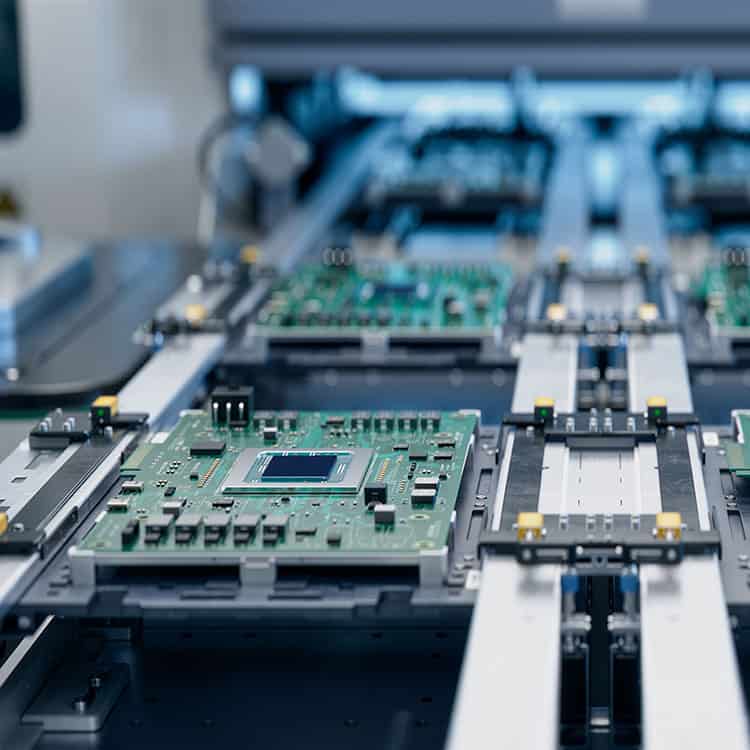

Applications of Laser Cutting in Electronics Manufacturing

Laser cutting plays a pivotal role in producing high-quality components for the electrical and electronics sector, including:

Display and Control Panels: Customised panels for consumer electronics and industrial controls are crafted with smooth edges and exact dimensions.

PCB Manufacturing: Lasers provide clean, precise cuts for printed circuit boards, ensuring no heat damage to delicate components and maintaining electrical integrity.

Microelectronic Housings: Laser technology is used to create compact, detailed housings for sensors, semiconductors, and microchips, ensuring precision fits and minimal material waste.

Connector Fabrication: The production of electrical connectors benefits from laser cutting’s ability to achieve intricate shapes and tight tolerances, critical for reliable connections.

The Science Behind Laser Cutting for Electronics

Laser cutting for electronic components utilises fibre and CO₂ lasers, depending on the material and application. Fibre lasers excel at processing metals, while CO₂ lasers are ideal for non-metal materials such as polycarbonate and acrylics.

The focused laser beam generates intense heat to vaporise or melt the material in the cutting path. Assist gases, such as nitrogen or air, help remove molten material and prevent oxidation. The result is a clean, burr-free cut that requires minimal post-processing. Advanced controls ensure precise replication of even the most complex designs, enabling manufacturers to produce consistently high-quality components.

Key Benefits of Laser Cutting in Electronics Manufacturing

High Precision: Laser cutting achieves micron-level accuracy, essential for miniaturised components used in modern electronics.

Non-Contact Processing: The laser’s non-contact nature prevents mechanical stress or damage to fragile components.

Material Versatility: Compatible with a wide range of materials, including metals, plastics, and ceramics, commonly used in the electronics industry.

Customisation Capabilities: Easily create intricate designs or custom components, adapting quickly to changing production demands.

Fast and Cost-Effective: High cutting speeds and minimal waste make laser cutting an efficient and economical choice for manufacturers.

TLM Laser Solutions for Electronics Manufacturing

At TLM Laser, we offer superior laser cutting solutions tailored for the electronics industry. Our partnership with Universal Laser Systems provides unparalleled options, Ideal for processing delicate non-metal materials, delivering clean and precise cuts for microelectronics.

With TLM Laser, you gain access to advanced technology and expert guidance to optimise your production processes.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.