Laser Cleaning for Electrical and Electronic Component Manufacturing

In the fast-evolving field of electrical and electronic component manufacturing, precision, cleanliness, and efficiency are paramount. Laser cleaning offers an advanced, non-contact solution for removing contaminants, residues, and oxides from delicate components, ensuring optimal performance and reliability.

How Laser Cleaning Works

Laser cleaning uses high-energy pulses of light to remove contaminants through ablation. The laser vaporises impurities without affecting the underlying material, offering a precise and efficient cleaning process ideal for delicate components.

Applications of Laser Cleaning in Electrical and Electronic Component Manufacturing

1. Pre-Bonding and Pre-Welding Surface Preparation

Lasers prepare component surfaces by removing residues and contaminants, enhancing adhesion and welding quality for tasks such as battery pack assembly and circuit board manufacturing.

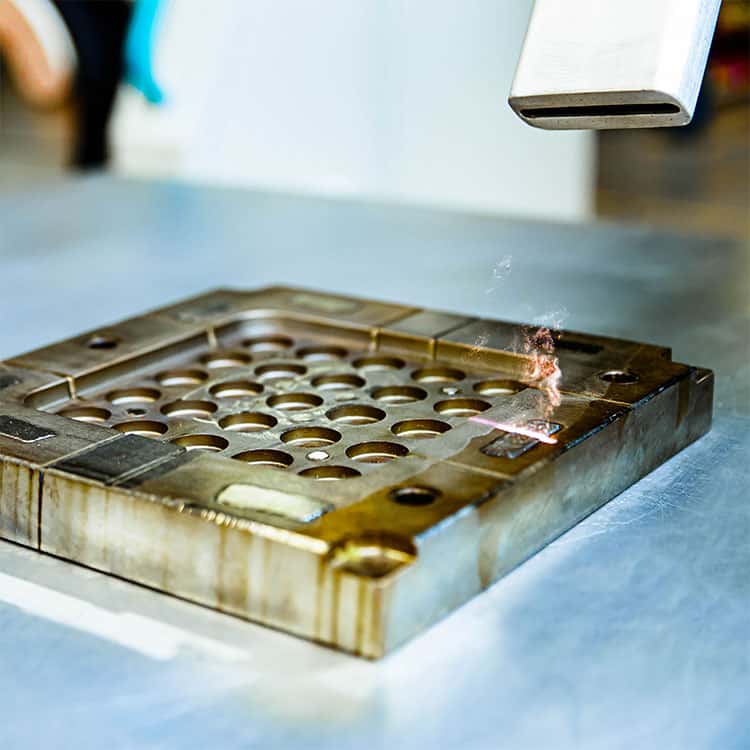

2. Die Cleaning for Moulding Processes

Moulds used in electronic component manufacturing can accumulate residues that affect product quality. Laser cleaning restores these moulds to their original state, ensuring consistency in production.

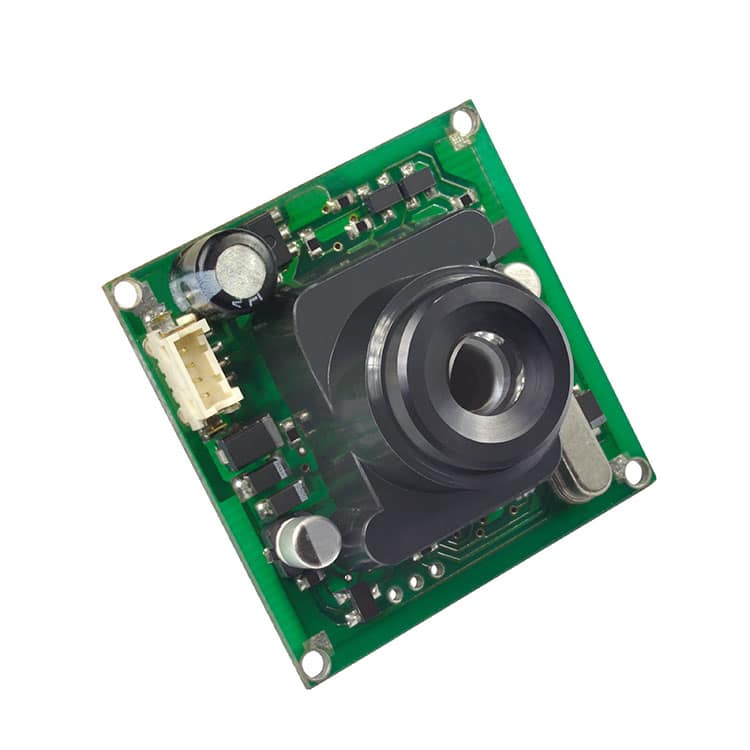

3. Cleaning Electrical Contacts and Connectors

Laser cleaning precisely removes oxides, dirt, and contaminants from electrical contacts and connectors, improving conductivity and ensuring reliable connections in high-performance systems.

Benefits of Laser Cleaning for Electrical and Electronic Component Manufacturing

1. Non-Contact and Non-Abrasive

Laser cleaning’s non-contact process preserves the integrity of delicate components, avoiding the risk of physical damage associated with traditional cleaning methods.

2. Environmentally Friendly

By eliminating the use of chemicals or solvents, laser cleaning reduces environmental impact and creates a safer workplace for operators.

3. High Precision and Repeatability

Laser cleaning’s precision ensures consistent results, even on intricate geometries, making it ideal for high-volume manufacturing environments.

4. Reduced Downtime

Automated laser cleaning systems streamline processes, reducing maintenance and production downtime, and improving overall efficiency.

5. Cost-Effective Over Time

Though initial investments may be higher, laser cleaning’s low operating costs, minimal consumables, and reduced maintenance requirements make it a cost-effective solution for manufacturers.

Compliance with Industry Standards

Laser cleaning systems adhere to stringent quality and safety standards, ensuring that manufacturers can meet the demands of critical industries like aerospace, automotive, and electronics.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.