Laser Processing for Electrical & Electronic Component Manufacturers

Precision is essential in the production of electrical and electronic components. TLM Laser provides advanced systems for marking, welding, cutting, and cleaning, helping manufacturers achieve high-quality results and meet the demands of modern electronics.

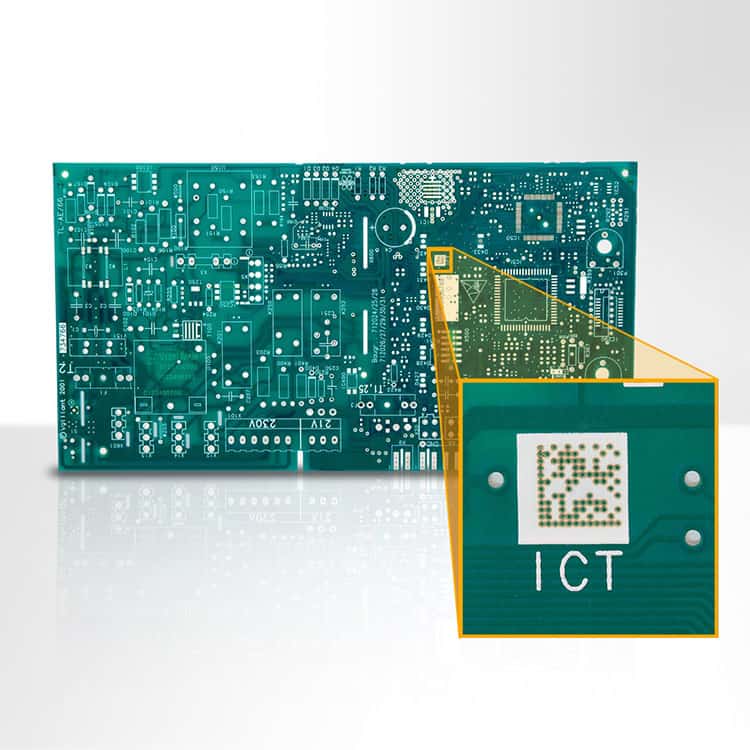

High-Precision Marking for Compact Electronics

TLM Laser supplies marking systems that deliver detailed, permanent marks on small and delicate components. Ideal for barcodes, serial numbers, and branding, these systems ensure compliance and traceability on circuit boards, connectors, and casings, meeting the precision demands of the electronics industry.

Welding Delicate Assemblies for Microelectronics

Our laser welding systems enable precise assembly of electrical and electronic components. With the ability to create strong, reliable bonds without thermal damage, these systems are perfect for delicate applications such as sensor production, battery manufacturing, and microelectronics.

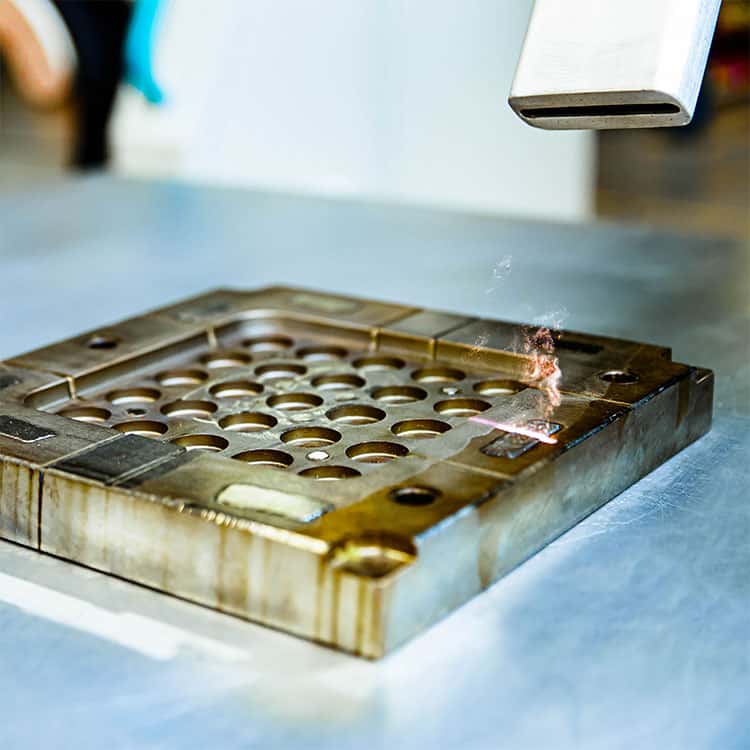

Cleaning Contact Surfaces for Optimal Performance

Laser cleaning systems from TLM Laser provide a non-abrasive method to clean and prepare surfaces of electronic components manufacturing moulds. By removing oxides, coatings, and contaminants, these systems ensure optimal manufacturing performance, supporting high-quality assembly processes.

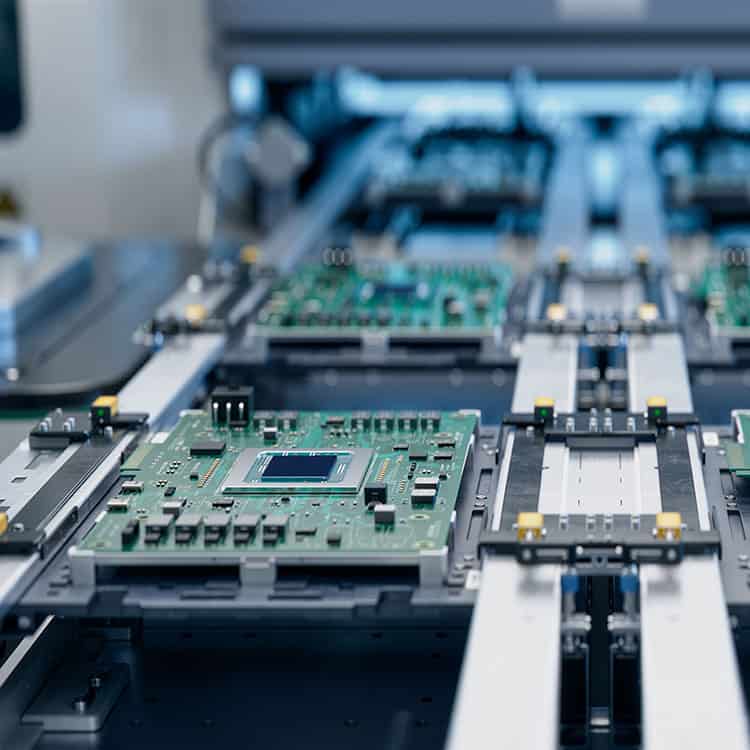

Cutting Solutions for Intricate Circuit Designs

TLM Laser’s cutting systems allow manufacturers to create intricate designs and patterns in electronic components. From cutting circuit boards to precision shaping of casings, our systems support efficient, high-quality production for a variety of electrical applications.

Innovate with Confidence

Laser Machines and Systems

Reviews

Don’t Just Take Our Word for It

Our Customers

Talk to Us!

Connect with our Technical & Support Team.