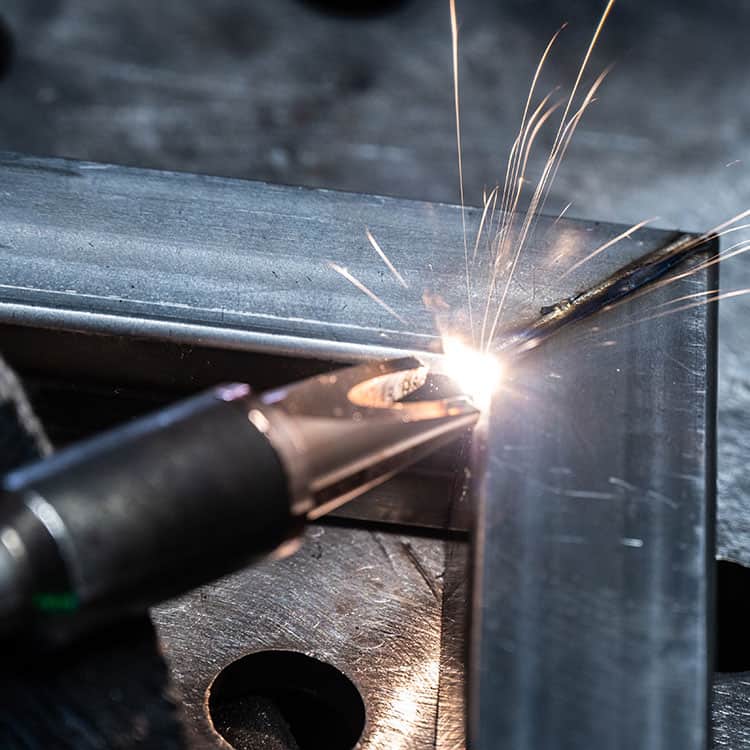

Laser Welding for the Contract Manufacturing Industry

Empower your contract manufacturing services with advanced laser welding systems designed for high-precision, repeatable results across multiple materials and components.

Why Choose Laser Welding for Contract Manufacturing?

Contract manufacturers often handle complex and varied welding tasks for multiple clients. Laser welding offers a precise, non-contact joining method ideal for components requiring minimal heat distortion and repeatable weld quality.

Whether producing automotive assemblies, medical tools, or aerospace parts, laser welding ensures strong, reliable welds while reducing post-processing requirements, making it perfect for contract manufacturers seeking efficiency and quality.

Laser Welding Applications for Contract Manufacturers

Micro-Welding for Electronics and Medical:

Laser welding enables micro-precision joining of small, delicate components such as sensor housings, implantable devices, and battery contacts with minimal heat impact.

Tool and Die Repair:

Contract manufacturers serving tool and die industries can benefit from laser welding systems that restore worn or damaged tools with pinpoint accuracy, extending their operational lifespan.

General Fabrication and Component Assembly:

Laser welding provides high-strength joints for automotive panels, aerospace components, and industrial machinery parts with minimal heat-affected zones, improving overall weld strength and reducing rework.

The Science Behind Laser Welding

Laser welding uses a focused laser beam to heat and melt the material’s surface, creating a fusion bond between components. The precision of the laser allows for deep penetration without excessive heat spread, minimising distortion.

Key techniques include:

Keyhole Welding: Used for deeper welds where the laser vaporises the material, creating a narrow cavity for deep penetration welding.

Conduction Welding: Suitable for thin materials, where heat spreads along the surface.

Key Benefits of Laser Welding for Contract Manufacturers

Precision and Control:

Achieve micro-accurate welds ideal for delicate or high-specification components.

Reduced Heat Distortion:

Perfect for thin materials and complex geometries where conventional welding could damage the material.

Increased Productivity:

Faster than TIG welding, with preset parameters for IPG LightWELD and reducing operator skill dependency.

TLM Laser Solutions for Contract Manufacturers

We supply leading laser welding systems from IPG Photonics, Alpha Laser, and Evosys, ideal for a range of contract manufacturing applications. Our systems offer:

- Handheld Laser Welders: Portable IPG LightWELD for flexible workshop use.

- Precision Micro-Welding Stations: Alpha Laser solutions for micro and tool repair work.

- Plastic Welding Systems: Evosys machines for plastic component joining.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.