Laser Cleaning for the Contract Manufacturing Industry

Contract manufacturers often require versatile cleaning solutions to prepare parts for finishing, painting, or bonding. Laser cleaning offers a chemical-free, non-abrasive alternative to traditional methods, ensuring effective surface preparation without damaging the base material.

Laser Cleaning Applications for Contract Manufacturers

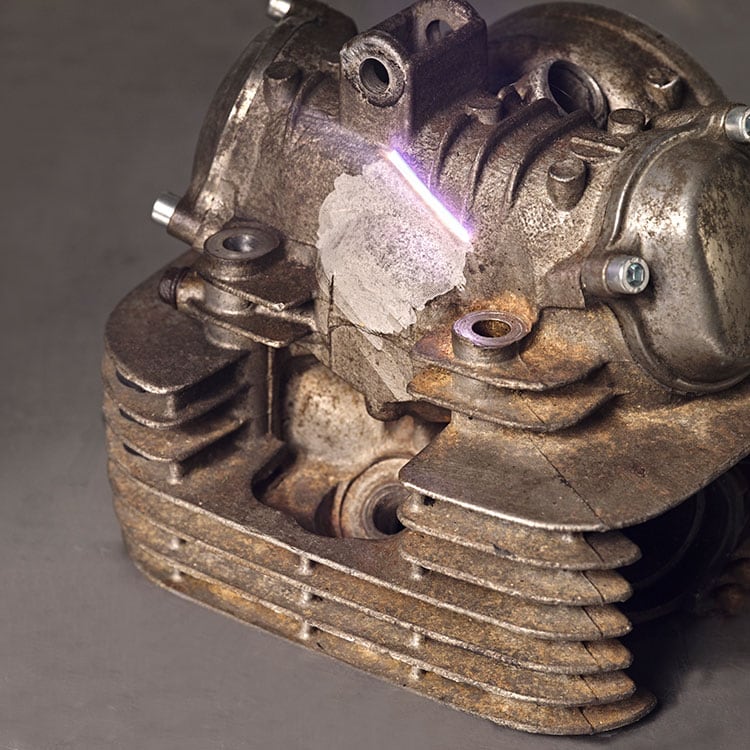

Rust & Oxide Removal:

Efficiently remove rust, oxide layers, and coatings from metal parts with minimal material loss, ideal for automotive restoration and industrial repairs.

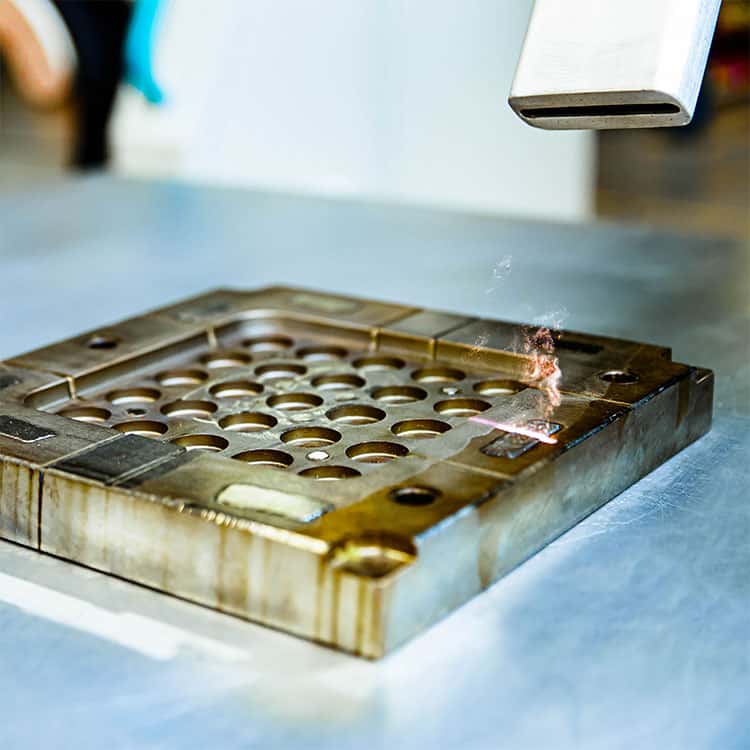

Mould Cleaning:

Non-contact cleaning of production moulds ensures minimal downtime and damage compared to abrasive cleaning methods.

Weld Preparation & Post-Cleaning:

Clean surfaces before and after welding to ensure strong weld joints and visual quality, particularly in precision fabrications.

The Science Behind Laser Cleaning

Laser cleaning relies on a process known as laser ablation, where a high-intensity pulsed laser beam is directed onto the surface of a material. The laser energy interacts with contaminants, causing them to either vaporise or be ejected from the surface.

The cleaning effect works due to the difference in energy absorption between the contamination layer and the base material. Contaminants such as rust, paint, or oxides absorb the laser’s energy more readily than the base material, ensuring only the unwanted layers are removed while the underlying surface remains undamaged.

Key technical aspects of the process include:

- Pulsed Laser Emission: Short bursts of energy minimise heat transfer, preventing damage to sensitive materials.

- Wavelength Control: Systems can be adjusted to optimise cleaning for different materials, such as metals, plastics, and stone.

- Selective Ablation: The laser can target specific layers of a material, making it ideal for multi-layer coatings and delicate parts.

The result is a highly controlled, chemical-free, and waste-free cleaning method suitable for a wide range of applications.

Key Benefits of Laser Cleaning for Contract Manufacturers

1. Precision and Control

Laser cleaning provides targeted removal of contaminants without damaging the base material, making it perfect for delicate components in medical, automotive, and electronics manufacturing.

2. Non-Contact and Non-Abrasive

Unlike abrasive blasting, laser cleaning does not physically touch the material, preserving its structure while effectively removing coatings, rust, and residues.

3. Chemical-Free and Eco-Friendly

Laser cleaning eliminates the need for hazardous chemical solvents, making it a sustainable choice for contract manufacturers seeking to reduce waste and improve workplace safety.

4. Cost-Effective and Low Maintenance

With minimal consumables required and reduced downtime for maintenance, laser cleaning systems provide long-term cost savings compared to traditional cleaning methods.

5. Versatile Across Industries

Whether working with automotive panels, aerospace components, or medical tools, laser cleaning can be adapted to meet the needs of multiple industries.

6. Improved Productivity

Laser cleaning allows for faster processing compared to manual or chemical cleaning methods, improving production flow and reducing labour costs.

TLM Laser Solutions for Contract Manufacturers

At TLM Laser, we supply state-of-the-art 4JET laser cleaning systems designed to meet the diverse needs of contract manufacturers. Our systems offer:

- Automated and Manual Cleaning Options: Adaptable to both batch production and on-demand job shop work.

- Modular Systems: Scalable to match your production volume and space requirements.

- Safe and Certified Designs: Built with integrated fume extraction and laser safety enclosures for compliance with health and safety standards.

We help businesses select the ideal system for their specific requirements, ensuring a smooth integration into existing workflows while improving quality and efficiency.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.