Laser Marking & Engraving for the Construction Industry

In the construction industry, durability and reliability are non-negotiable. From tools and machinery to structural components, every item must meet stringent safety, traceability, and quality standards. Laser marking and engraving provide a precise, permanent, and durable solution for identifying and marking construction equipment, tools, and components. With applications ranging from branding and compliance marking to inventory tracking, laser technology has become indispensable in this demanding sector.

Applications of Laser Marking in Construction

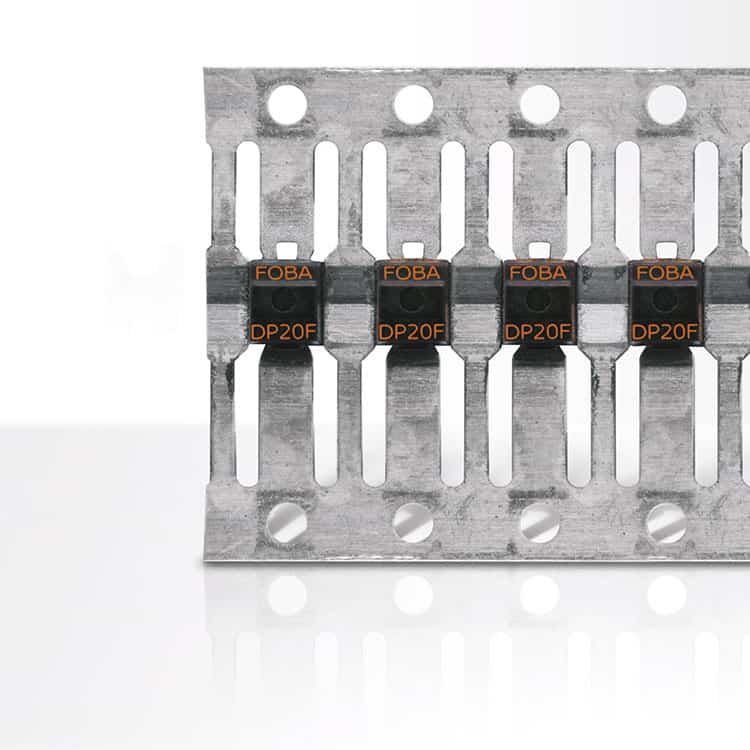

Tool and Equipment Identification:

Ensure tools and equipment are identifiable with permanent serial numbers, barcodes, or QR codes to prevent loss or theft and aid in inventory management.

Compliance and Safety Marking:

Display compliance certifications, load capacities, and safety warnings directly on construction equipment, adhering to industry regulations.

Branding and Logos:

Enhance your company’s visibility and brand recognition by permanently engraving logos or company information on machinery and tools.

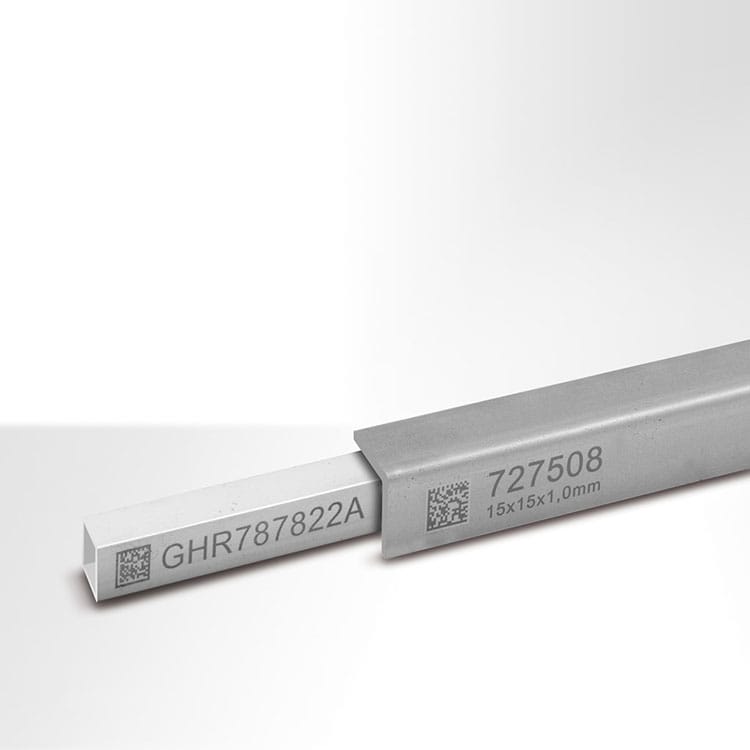

Material Traceability:

Laser marking ensures traceability of components like steel beams, pipes, and concrete reinforcements, aiding in quality assurance and safety audits.

Customised Markings:

Mark specifications, installation instructions, or project details on components for easy identification and assembly on-site.

How Laser Marking Works

Laser marking works by directing a concentrated laser beam onto a material’s surface to alter its properties. Different techniques are used depending on the application:

- Annealing: For metals, this process changes the colour of the material surface without removing any material, creating high-contrast, corrosion-resistant marks.

- Engraving: Removes material to create deep, long-lasting marks, suitable for harsh conditions.

- Etching: Creates precise, shallow marks for intricate designs or detailed information.

- Ablation: Removes coatings or surface layers to reveal underlying material for a high-contrast mark.

The non-contact nature of laser marking ensures that even the most delicate or irregularly shaped items can be marked without damage.

Key Benefits of Laser Marking in Construction

Durability and Resistance:

Laser marks withstand extreme environmental conditions, such as UV exposure, chemicals, abrasion, and temperature fluctuations, making them ideal for the construction industry.

Precision and Versatility:

Laser technology allows for precise, high-contrast markings on various materials, including metals, plastics, and composites, ensuring clarity and legibility.

Eco-Friendly and Cost-Effective:

Laser marking is a consumable-free process, reducing environmental impact and operational costs compared to traditional marking methods.

Enhanced Traceability:

Unique identifiers such as barcodes and serial numbers ensure seamless tracking of tools and components, improving supply chain efficiency and accountability.

Compliance and Safety:

Permanent markings ensure adherence to regulatory standards, providing essential safety information and certifications.

Customisation and Flexibility:

Whether for branding, compliance, or operational needs, laser systems offer unmatched adaptability for various applications.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.