Laser Marking & Engraving for the Coin & Die Industry

Revolutionising the coin and die industry with precise, durable, and efficient laser marking and engraving solutions.

The Importance of Laser Marking for the Coin and Die Industry

The coin and die industry relies on precision and durability to create intricate designs, maintain tool longevity, and ensure the highest quality standards. Laser marking and engraving provide unmatched accuracy for engraving complex patterns, text, and security features onto dies, moulds, and coins. These non-contact methods ensure that even the most detailed designs are flawlessly replicated, while preserving the integrity of the substrate.

Compared to traditional engraving techniques, laser technology reduces tool wear, minimises material waste, and offers unparalleled flexibility. It also supports the addition of anti-counterfeiting measures and traceable identifiers, essential for currency and high-value items.

The Science Behind Laser Marking for Automotive Components

Laser technology enhances various processes in the coin and die industry:

Coin Minting Dies

Laser engraving ensures the precise replication of intricate patterns and lettering onto coin minting dies, preserving design fidelity across high-volume production.

Customised Commemorative Coins

Laser marking enables customisation with fine details and textures for commemorative or limited-edition coins, enhancing their uniqueness and value.

Embossing and Stamping Tools

Engraving for embossing or stamping tools creates long-lasting impressions for high-quality manufacturing.

Anti-Counterfeiting Measures

Security features, such as microtext, holograms, or unique serial numbers, can be engraved onto coins or dies to prevent counterfeiting.

Serialisation and Traceability

Adding serial numbers or unique identifiers to dies or coins ensures complete traceability throughout the production process.

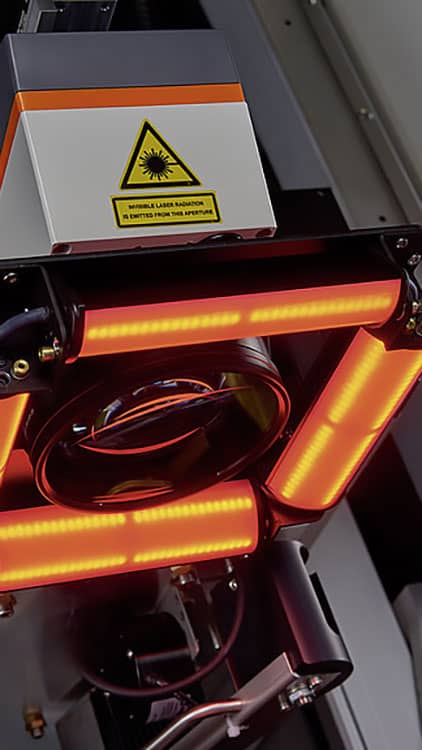

The Science Behind Laser Marking in the Coin and Die Industry

Laser marking and engraving work by delivering highly concentrated beams of light to the material’s surface, precisely removing layers or modifying its properties. Several methods are used in the coin and die industry:

Deep Laser Engraving

This process removes significant layers of material to create deep, durable markings suitable for high-wear applications like coin minting dies.

3D Laser Engraving

By layering material removal, 3D laser engraving creates highly detailed and intricate designs on coins and dies, replicating complex textures and shapes.

Laser Annealing

Used on metals, laser annealing oxidises the surface to create dark, smooth markings without removing material, ideal for creating detailed designs with a clean finish.

Microtext Marking

This process creates high-resolution markings visible only under magnification, adding an essential layer of security for currency and collectable coins.

Our Advanced Laser Solutions for The Coin & Die Industry

Laser marking and engraving bring transformative advantages to the coin and die industry:

Exceptional Precision

Create intricate, detailed patterns and designs with micron-level accuracy.

Enhanced Durability

Laser-engraved dies and tools offer extended lifespans, reducing wear and replacement costs.

Anti-Counterfeiting Measures

Incorporate microtext, holograms, and serial numbers to protect coins and dies from counterfeiting.

Cost Efficiency

Non-contact laser marking reduces material waste and tool wear, leading to significant cost savings.

Environmentally Friendly

The process eliminates the need for consumables such as inks and chemicals, supporting eco-friendly manufacturing practices.

Flexibility

Adapt designs easily for different coins, dies, and embossing tools without requiring physical templates.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.