Laser Marking & Engraving for the Automotive Industry

In the automotive industry, precision, durability, and traceability are critical for success. Laser marking and engraving provide unmatched capabilities for identifying, tracking, and personalising vehicle components. From intricate parts to larger assemblies, laser technology supports a broad range of applications, ensuring compliance, quality, and efficiency at every stage of automotive production.

Applications of Laser Marking in Automotive Manufacturing

Modern vehicles are made up of thousands of individual components, each requiring accurate coding and marking for traceability and compliance. Laser marking delivers permanent, tamper-proof identification across a variety of materials. Key applications include:

Gearbox Component Marking:

Ensures traceability and compliance for critical drivetrain components.

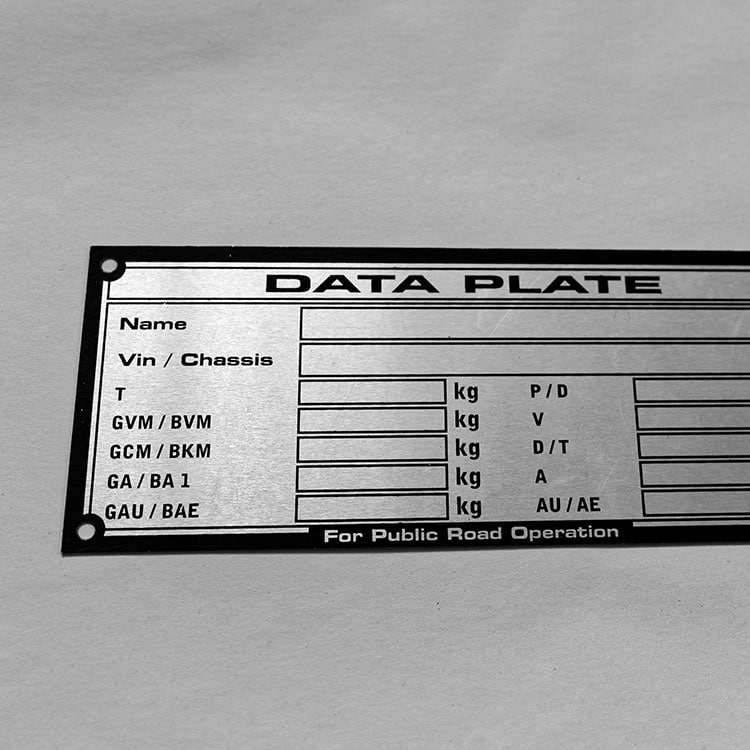

VIN Plates and Identification Labels:

Permanent marking of Vehicle Identification Numbers (VINs) and labels ensures durability and tamper resistance, even in harsh environments.

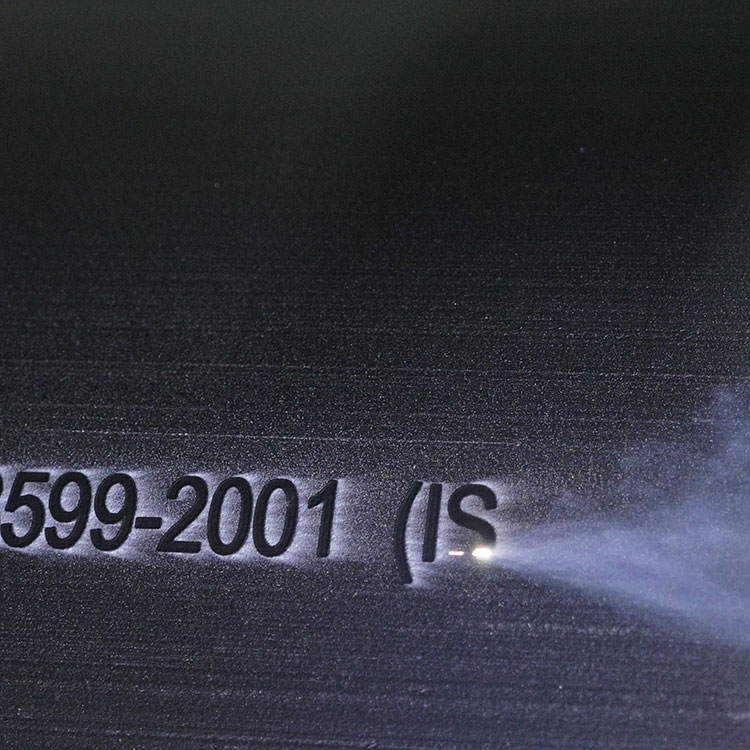

Vehicle Glass Security Code Etching:

Adds an anti-theft measure by etching security codes onto windows and windscreens.

Day/Night Marking for Displays and Controls:

Laser marking enables illuminated controls and interfaces that are easy to read both during the day and at night.

2D Matrix Marking:

Provides high-density data storage for motorsport components, offering superior traceability throughout the supply chain.

The Science Behind Laser Marking for Automotive Components

Laser marking uses a concentrated beam of light to create high-precision marks on various materials. This process is versatile and customisable depending on the specific application:

- Ablation: Removes coatings on surfaces such as dashboards or displays for Day/Night marking.

- Engraving: Creates deep, durable markings for parts that endure high wear, such as gearbox components.

- Annealing: Produces high-contrast marks on stainless steel and other metals for long-term readability.

Laser marking’s ability to adapt to different materials and applications makes it a preferred choice for the automotive industry.

Key Benefits of Laser Marking in the Automotive Industry

Enhanced Traceability:

Laser marking ensures all parts, from the smallest components to entire vehicles, are easily identifiable and traceable throughout production and beyond.

Eco-Friendly and Clean Process:

Unlike traditional marking methods, laser marking is a consumable-free process that eliminates the need for inks, chemicals, or physical abrasives.

Durability and Longevity:

Marks created by lasers are resistant to wear, corrosion, and environmental factors, ensuring they last the lifetime of the vehicle.

High Precision and Repeatability:

Laser marking systems produce consistent, high-quality results, reducing scrap and rework in manufacturing.

Material Versatility:

From metals and plastics to glass and composites, laser marking works on virtually all materials used in modern vehicles.

Our Advanced Laser Solutions for Automotive

FOBA offers state-of-the-art laser marking systems tailored to the automotive sector. Highlights include:

MOSAIC Vision System: Enables fixtureless marking for parts of varying sizes, reducing production setup times.

IMP (Intelligent Mark Positioning): Automatically aligns marks for precision on complex components.

Point & Shoot Technology: Simplifies manual marking alignment for small to medium-sized automotive parts.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.