Laser Welding for the Aerospace Industry

Achieve unparalleled precision and reliability with laser welding for the aerospace industry. Designed to meet stringent safety and performance standards, our solutions provide unmatched quality for critical components and assemblies.

The Importance of Laser Welding for Aerospace

The aerospace industry demands the highest levels of accuracy, strength, and safety in component manufacturing. Laser welding addresses these needs with unmatched precision, minimal heat distortion, and consistent results. Whether working with lightweight alloys or high-strength materials, laser welding ensures structural integrity and compliance with strict aerospace regulations.

This advanced technology also supports innovative designs, enabling manufacturers to meet the evolving needs of the aerospace sector while maintaining cost efficiency and reliability.

Key Applications of Laser Welding in Aerospace

Laser welding is widely adopted in the aerospace sector due to its versatility and performance. Applications include:

Repair and Maintenance: Restore critical parts, such as turbine blades and structural elements, with high precision, reducing downtime and costs.

Engine Components: Create durable, heat-resistant welds for jet engines, turbines, and exhaust systems that withstand extreme temperatures and stress.

Structural Assemblies: Seamlessly join lightweight materials such as titanium and aluminium to optimise aircraft weight without compromising strength.

Fuel Systems: Fabricate leak-proof fuel tanks, pipelines, and connectors with precise, clean welds.

Avionics and Electronics: Assemble compact electronic components, ensuring reliability in navigation and communication systems.

The Science Behind Laser Welding in Aerospace Manufacturing

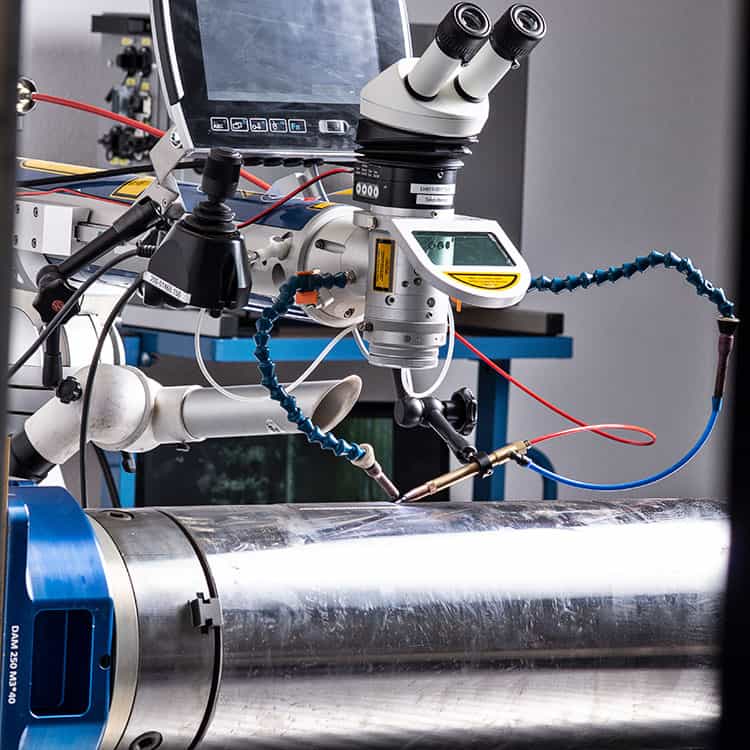

Laser welding employs a concentrated beam of light to create high-precision welds. This technology is particularly effective in aerospace applications, where lightweight materials like aluminium, titanium, and advanced alloys are commonly used.

The process generates intense heat in a controlled manner, allowing for deep penetration and high-strength welds. Unlike traditional welding methods, laser welding minimises the heat-affected zone, preserving the material’s integrity and reducing the risk of warping or thermal damage.

Automation enhances the accuracy and repeatability of laser welding, ensuring consistent quality in high-volume production. This is critical for aerospace manufacturers, where each component must meet rigorous standards for safety and performance.

Key Benefits of Laser Welding in Aerospace

High Precision: Laser welding delivers unmatched accuracy, ensuring flawless results even in complex assemblies.

Minimal Heat Distortion: Controlled heat application preserves the properties of lightweight and heat-sensitive materials.

Durability: Welds are exceptionally strong and resistant to environmental stressors, ensuring longevity and reliability.

Cost Efficiency: Automation reduces production time and waste, providing significant cost savings.

Compliance with Standards: Laser welding ensures adherence to stringent aerospace regulations and quality requirements.

TLM Laser Solutions for Aerospace Applications

At TLM Laser, we supply state-of-the-art laser welding systems tailored for aerospace manufacturing. Partnering with Alpha Laser, we provide advanced solutions that deliver precision, reliability, and compliance with industry standards.

Our laser systems are ideal for producing and maintaining critical components, from jet engines to structural assemblies. With a focus on efficiency and quality, we help aerospace manufacturers optimise their production processes while reducing costs and ensuring safety.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.