Laser Marking & Engraving for the Aerospace Industry

In the aerospace industry, precision, traceability, and durability are non-negotiable requirements. Laser marking and engraving have become essential tools for meeting these demands, offering permanent, high-contrast, and damage-free solutions that comply with stringent industry standards. At TLM Laser, we provide advanced laser systems from trusted partners like FOBA, delivering tailored marking and engraving solutions for a wide range of aerospace applications.

Applications of Laser Marking & Engraving in Aerospace

Component Identification and Traceability

Aerospace parts, from turbine blades to fasteners, require clear and permanent identification for regulatory compliance, inventory management, and maintenance. Laser marking ensures high-contrast, durable markings, including serial numbers, QR codes, and Data Matrix codes, that remain intact even in extreme conditions.

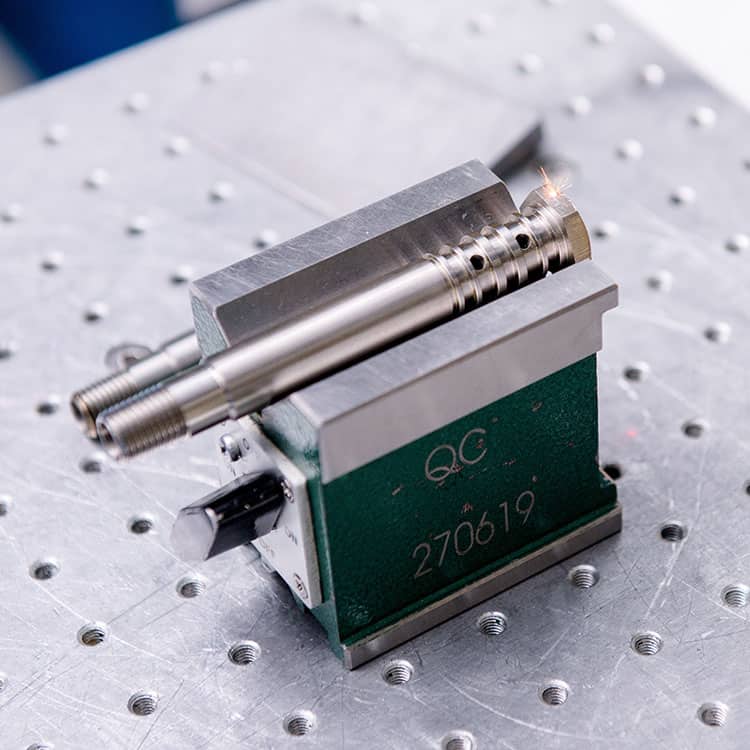

Tool and Mould Engraving

Laser engraving provides precise, repeatable results for engraving moulds and tooling used in the manufacturing of aerospace components. This process enhances the quality and consistency of parts while ensuring long-lasting performance.

Day/Night Markings

For cockpit controls and dashboard panels, laser marking is used to create Day/Night marks. These markings, visible under various lighting conditions, are essential for operational safety and compliance with aerospace standards.

Part Authentication and Anti-Counterfeiting

Aerospace manufacturers face significant risks from counterfeit components. Laser marking offers secure solutions by embedding tamper-proof marks or micro-text that cannot be easily replicated, ensuring authenticity throughout the supply chain.

Heat-Resistant Markings

Components exposed to high temperatures, such as engine parts, require markings that withstand thermal stress. Laser marking creates annealed marks that maintain clarity and contrast without compromising material integrity.

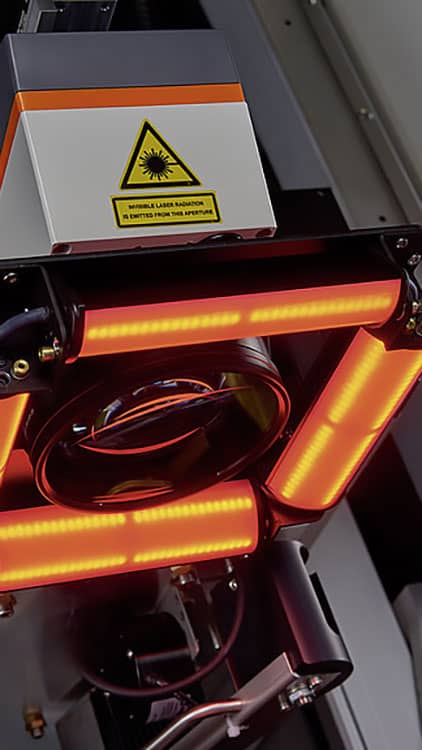

How Laser Marking Works in Aerospace

Laser marking uses focused laser beams to create permanent marks by altering the surface properties of the material. Techniques include:

- Annealing: Produces oxidation marks without removing material, ideal for stainless steel and titanium.

- Engraving: Removes material to create deeper, highly durable marks for heavy-duty applications.

- Etching: Removes surface material to create contrast marks with a shallow depth.

These methods ensure that markings are resistant to wear, corrosion, and extreme environmental conditions, making them perfect for the aerospace industry.

Key Benefits of Laser Marking & Engraving in Aerospace

Precision and Repeatability

Advanced laser systems deliver micron-level precision, ensuring accurate markings on intricate aerospace components. This repeatability is crucial for maintaining compliance and quality.

Material Versatility

Laser marking works effectively on aerospace-grade materials such as stainless steel, titanium, composites, and alloys, ensuring flexibility in application.

Compliance with Industry Standards

Laser marking ensures adherence to aerospace standards such as AS9100 and FAA regulations, providing tamper-proof traceability for parts and components.

Durability and Resistance

Laser markings are designed to withstand extreme conditions, including high temperatures, pressure, and corrosive environments, ensuring longevity in aerospace applications.

Cost Efficiency and Sustainability

Laser marking eliminates the need for consumables like inks or chemicals, reducing operational costs and supporting environmentally friendly manufacturing practices.

Our Advanced Laser Solutions for Aerospace

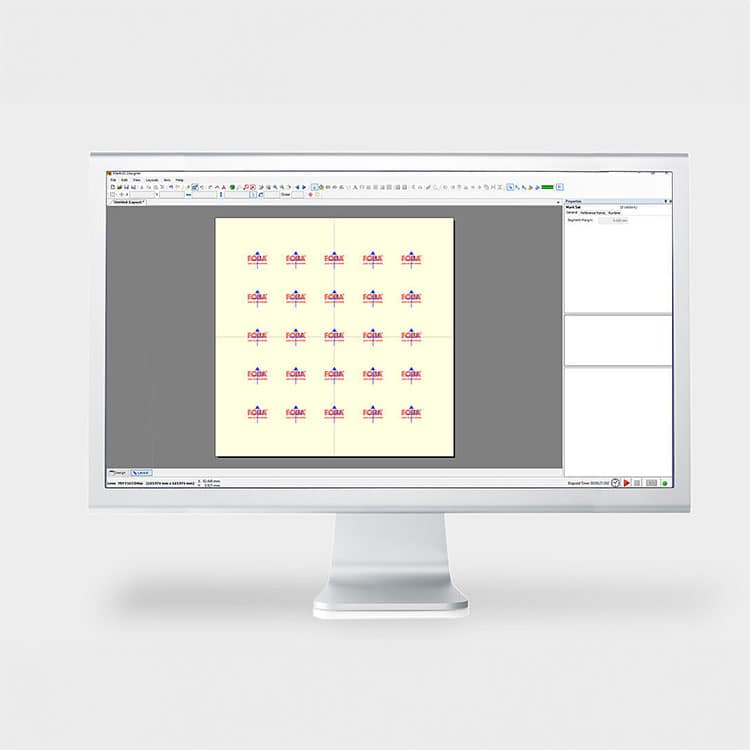

At TLM Laser, we supply cutting-edge laser marking systems equipped with FOBA’s vision-based technologies, including:

MOSAIC: Enables precise, fixtureless marking on complex geometries.

IMP (Intelligent Mark Positioning): Ensures perfect alignment and precision, reducing waste and improving production efficiency.

Point & Shoot: Simplifies manual marking tasks, ensuring accuracy and ease of use.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.