Laser Cleaning for the Aerospace Industry

Laser cleaning offers unparalleled precision and efficiency for maintaining and preparing critical aerospace components. By utilising high-energy laser pulses, contaminants such as oxides, coatings, and residues are safely removed without damaging the underlying material. TLM Laser, in partnership with 4JET, provides advanced laser cleaning solutions tailored to the exacting standards of the aerospace industry.

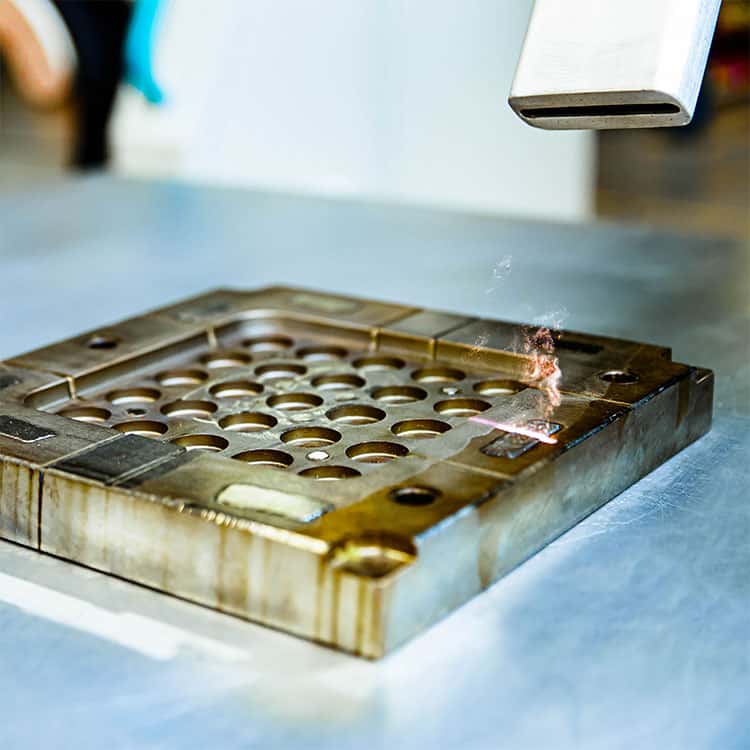

How Laser Cleaning Works

Laser cleaning uses the principle of ablation, where the laser beam targets and vaporises contaminants on the surface. The process is highly controlled, leaving the base material untouched and ensuring consistent cleaning results. Its non-contact nature is particularly beneficial for sensitive aerospace components.

Applications of Laser Cleaning in Aerospace

1. Surface Preparation for Bonding and Coatings

Prepare aircraft surfaces for bonding, painting, or coating applications by removing contaminants like oxides, grease, or residues. Laser cleaning ensures flawless adhesion, critical for maintaining safety and durability in aerospace structures.

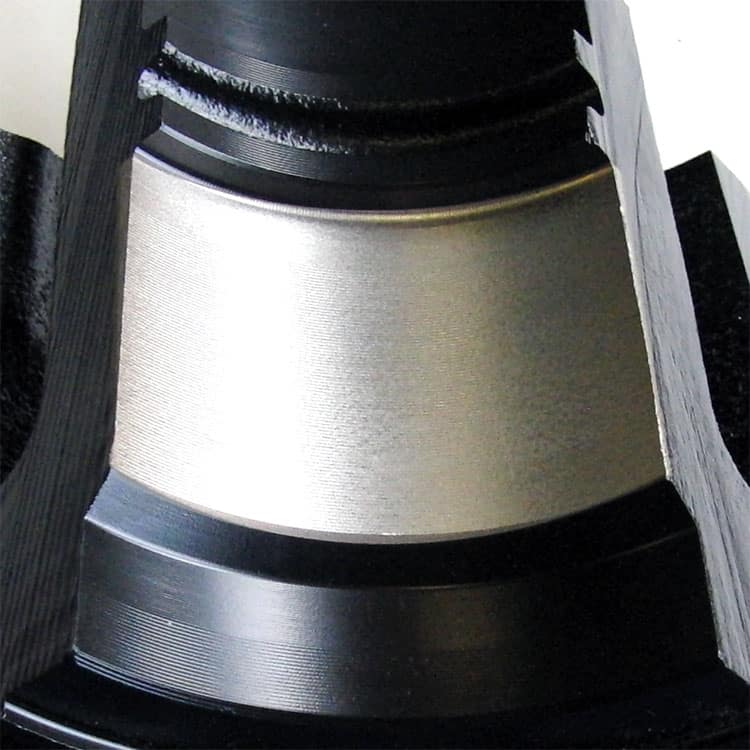

2. Removal of Oxidation and Corrosion

Safely eliminate oxidation layers and corrosion from sensitive components, such as landing gear or wing structures. This precision cleaning enhances the performance and lifespan of these vital parts.

3. Paint Removal from Aircraft Surfaces

Laser cleaning simplifies the paint removal process, eliminating the need for abrasive methods or chemicals that can harm underlying materials. Its precision allows for selective paint stripping, reducing waste and costs.

4. Maintenance and Restoration of Historical Aircraft

Restore historical aircraft components with a non-invasive cleaning method that preserves their structural and aesthetic integrity. Laser cleaning’s ability to target specific contaminants makes it ideal for delicate restoration tasks.

Benefits of Laser Cleaning for Aerospace

1. Non-Abrasive and Safe for Delicate Parts

The precision of laser cleaning protects sensitive materials and intricate designs, ensuring no damage to aerospace components. This makes it ideal for cleaning parts like turbine blades or composite surfaces.

2. Environmentally Friendly Process

Unlike traditional methods, laser cleaning generates minimal waste and does not require harmful chemicals, making it an eco-friendly solution for the aerospace industry. This aligns with environmental regulations and sustainability goals.

3. Cost and Time Efficiency

Laser cleaning reduces downtime and increases operational efficiency by streamlining cleaning and preparation processes. Its automation-ready systems further enhance productivity in aerospace manufacturing.

4. Enhanced Component Longevity

By precisely removing contaminants without impacting the substrate, laser cleaning improves the durability and performance of aerospace components, ensuring safety and reliability over time.

Why Laser Cleaning Is Transforming Aerospace

Regulatory Compliance

Laser cleaning aligns with aerospace standards such as ISO 9001 for quality management and AS9100 for aerospace manufacturing. Its precision and reliability make it a trusted technology in the aerospace sector.

Minimised Downtime

With its speed and efficiency, laser cleaning reduces the time required for maintenance, ensuring aircraft spend less time on the ground and more time in the air.

Cost-Effective Operation

By eliminating consumables and reducing waste, laser cleaning systems offer significant long-term cost savings, even with the initial investment.

Answering Your Questions

Frequently Asked Questions

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.