Laser Marking Explained

Laser marking is a versatile and precise technique used to create permanent marks on various materials for identification, traceability, and branding purposes. The process leverages focused laser beams to alter the surface of a material without physical contact, delivering high-resolution results with unmatched durability. At TLM Laser, in partnership with FOBA, we provide advanced laser marking solutions tailored for diverse industrial applications.

What Is Laser Marking?

Laser marking involves the use of a concentrated laser beam to create high-contrast marks on surfaces. The laser interacts with the material to produce markings such as text, logos, serial numbers, barcodes, and data matrices. These markings are resistant to wear and environmental factors, ensuring longevity and reliability.

Laser Marking vs. Laser Engraving

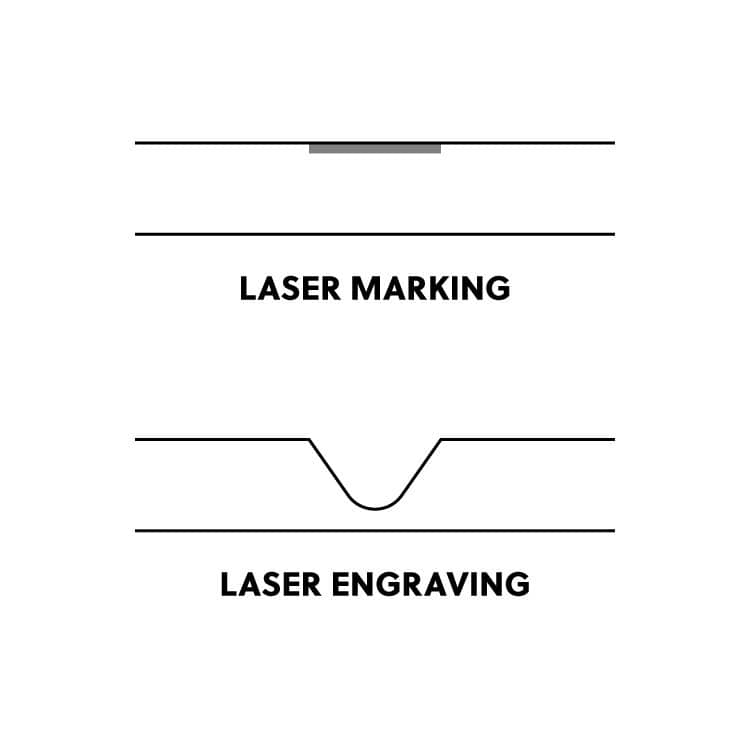

While laser marking and engraving are often used interchangeably, they differ significantly in their processes and outcomes:

Laser Marking: Alters the surface of a material by discolouration, oxidation, or annealing, leaving the surface intact. Ideal for applications requiring smooth, non-invasive markings, such as medical devices or electronics.

Laser Engraving: Removes material to create a recessed mark, resulting in a deeper and more tactile imprint. This process uses high-intensity laser pulses to remove material layer by layer, creating a tactile imprint. It is commonly used in automotive and aerospace industries, where marks must endure extreme conditions.

The Science Behind Laser Marking

Laser marking works by directing a high-energy laser beam onto a specific area of the material, resulting in precise and permanent markings. The laser interacts with the material’s surface to induce physical or chemical changes, which can be customised to achieve a variety of effects depending on the process and material type.

Annealing marking is a technique often used on metals like stainless steel. The laser heats the material’s surface, causing oxidation beneath it. This creates a darkened mark without removing any material, ensuring a smooth surface. It is particularly valued in industries such as medical manufacturing, where corrosion resistance and sterility are crucial.

Foaming is a process designed for plastics. The laser generates tiny bubbles within the material, which reflect light and result in a raised, lighter-coloured mark. This technique provides excellent contrast, especially on dark plastic surfaces, and is often used for ID tags or component markings.

Carbonising, on the other hand, is used to create dark contrasts on light surfaces by reducing oxygen in the material. This process is particularly effective on organic materials like leather or paper, producing aesthetically pleasing and permanent marks.

Colour marking represents a more advanced application of laser technology. By carefully adjusting laser parameters, manufacturers can create vibrant marks in various colours. This method is especially popular for branding and decorative applications on metals such as stainless steel or titanium, delivering visually striking results.

These processes highlight the versatility and precision of laser marking, making it an essential tool across industries for both functional and decorative purposes. Each method is designed to meet specific requirements, ensuring high-quality outcomes tailored to the needs of the application.

Benefits of Laser Marking

1. Permanent and High-Quality Marks

Laser marking produces indelible, high-contrast marks that can withstand extreme environments.

2. Non-Contact and Precise

The laser beam interacts with the material without physical contact, ensuring no mechanical stress or damage.

3. Environmentally Friendly

Laser marking eliminates the need for consumables such as inks or chemicals, reducing waste and operational costs.

4. High-Speed and Automated

With advanced systems like FOBA’s IMP and Mosaic technologies, laser marking integrates seamlessly into production lines for high-speed and accurate markings.

5. Enhanced Traceability

Laser marking enables the integration of barcodes, serial numbers, and data matrices for superior traceability in industries like aerospace and medical devices.

Why Choose TLM Laser for Your Laser Marking Needs?

At TLM Laser, we deliver state-of-the-art laser marking systems that align with your specific needs, ensuring precision, efficiency, and compliance with industry standards. In partnership with FOBA, we offer the latest innovations in laser marking technology, from vision systems to custom software solutions.

Reviews

Don’t Just Take Our Word for It

Our Customers

Blog Posts

Laser News & Information

Talk to Us!

Connect with our Technical & Support Team.